If you want clean, precise holes every time you use your drill press, holding the drill press vice correctly is key. You might think it’s simple, but even a small mistake can lead to uneven drilling or damage to your workpiece.

You’ll discover easy steps to secure your drill press vice like a pro, so your projects come out perfect and safe. Keep reading to learn how to boost your drilling accuracy and confidence with just a few smart adjustments.

Credit: www.youtube.com

Choosing The Right Drill Press Vice

Choosing the right drill press vice is key for safe and accurate drilling. The vice holds your workpiece firmly. A good fit prevents slipping and damage. This section helps you pick the perfect vice for your drill press. Consider types, build quality, and size to match your needs.

Types Of Drill Press Vices

There are several types of drill press vices. Plain vices hold the work steady with fixed jaws. Swivel vices rotate for angle drilling. Quick-release vices open fast for easy work changes. Each type suits different tasks and materials. Pick one that fits your project style.

Material And Build Quality

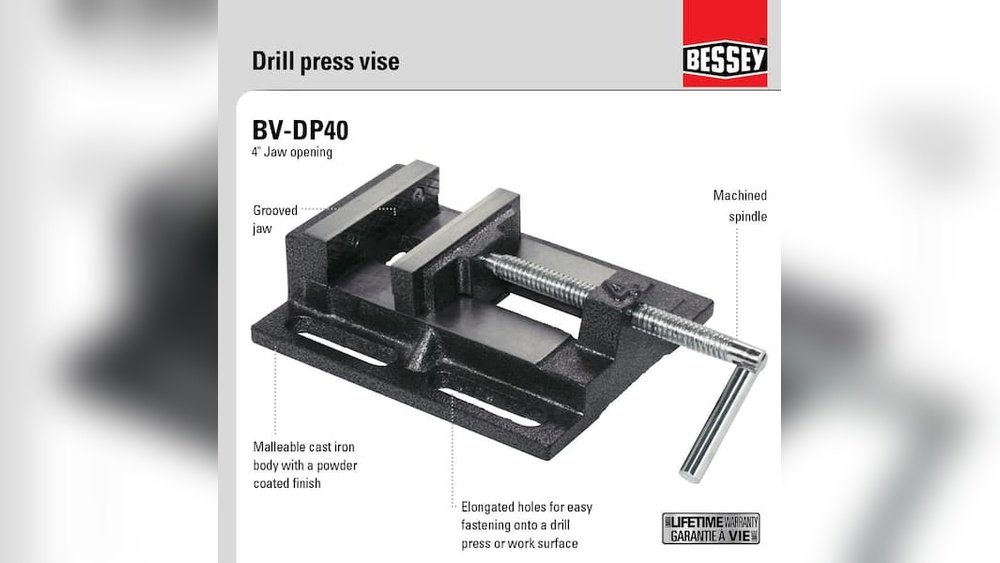

Strong materials ensure the vice lasts long. Cast iron is common and very durable. Steel vices offer extra strength and resistance. Check the finish for rust protection. A well-built vice keeps steady under pressure. Avoid cheap plastics or weak metals.

Size And Jaw Capacity

Size matters for holding different workpieces. Jaw capacity means the maximum width the vice can hold. Small vices fit tiny parts, large ones hold bigger pieces. Match the size with your typical project needs. Ensure the vice fits your drill press table too.

Credit: www.grozusa.com

Preparing The Drill Press Table

Preparing the drill press table is an important step before holding the drill press vice. A clean and level table ensures accurate drilling. Proper alignment helps avoid mistakes and keeps the workpiece stable. Take time to set up the table carefully.

Cleaning And Leveling The Surface

Start by removing dust, dirt, and metal shavings from the table. Use a brush or cloth to clear all debris. A clean surface stops the vice from slipping during drilling.

Next, check if the table is level. Use a spirit level tool for this task. Adjust the table’s height or position until it is flat and even. A level surface improves drill precision and safety.

Aligning The Table With The Drill Bit

Place the drill bit in the chuck and lower it toward the table. Move the table so the bit lines up with the center mark. This alignment helps the drill bit hit the exact spot.

Double-check the position by lowering the bit just above the table. Adjust the table angle if needed to keep the bit straight. Proper alignment protects the drill bit and the workpiece.

Mounting The Vice Securely

Mounting the vice securely on your drill press is key for safe and precise work. A firm hold prevents movement during drilling. It also protects your materials and tools from damage. Follow these steps to mount your vice correctly and keep it stable.

Positioning The Vice Correctly

Place the vice on the drill press table. Align it so the jaws face the drill bit. Make sure the vice sits flat and straight. This helps the drill bit enter the material at the right angle. Check there is enough space for the drill to move freely.

Using Bolts And Clamps

Secure the vice using bolts through the table holes. Tighten the bolts firmly to stop any movement. Use clamps if your table has no holes. Clamp the vice tightly to the table edge. Both bolts and clamps keep the vice steady during drilling.

Checking Stability And Tightness

Test the vice by trying to move it by hand. It should not shift or wobble. Tighten bolts or clamps more if needed. Recheck after a few uses to keep the vice secure. A stable vice improves drilling accuracy and safety.

Aligning The Workpiece

Aligning the workpiece on a drill press vice is key to accurate drilling. Proper alignment ensures the drill hits the exact spot needed. This step prevents mistakes and keeps your project safe. Take time to set the workpiece right before starting.

Centering The Material

Place the material in the vice so the drill bit hits the center. Use a ruler or marking tool to find the exact spot. Adjust the workpiece until the mark lines up with the drill bit. Centering helps avoid uneven holes and damage.

Adjusting Jaw Pressure

Tighten the vice jaws just enough to hold the workpiece firmly. Too much pressure can damage the material or bend it. Too little pressure lets the workpiece move during drilling. Find the balance to keep the material secure and safe.

Avoiding Workpiece Movement

Check the workpiece for movement by trying to shift it slightly. If it moves, tighten the jaws more or reposition the material. Use clamps or supports for extra stability if needed. A stable workpiece means cleaner, safer drilling results.

Safety Tips While Using Drill Press Vice

Using a drill press vice safely is important to avoid accidents. The vice holds your workpiece steady during drilling. Unsafe use can cause injury or damage to the drill press and the workpiece. Follow safety tips to protect yourself and ensure the best results.

Wearing Protective Gear

Always wear safety goggles to protect your eyes from flying debris. Use gloves to shield your hands from sharp edges and heat. Wear ear protection if the drill press is loud. Avoid loose clothing or jewelry that can catch in moving parts.

Avoiding Over-tightening

Do not tighten the vice too much. Over-tightening can damage the vice or crush the workpiece. Tighten the vice just enough to hold the item firmly. Check the grip before starting the drill press to prevent slipping.

Regular Maintenance Of The Vice

Keep the drill press vice clean and free of dust and metal shavings. Oil the moving parts regularly to ensure smooth operation. Inspect the vice for cracks or wear before each use. Replace parts if you notice damage to avoid failure during drilling.

Common Mistakes To Avoid

Holding a drill press vice correctly is key for safe and accurate drilling. Many users make simple mistakes that reduce work quality and cause damage. Avoiding these errors will help you get the best results and protect your tools.

Ignoring Vice Alignment

Proper alignment of the vice is essential. If the vice is not aligned with the drill bit, holes may be off-center. This can damage the workpiece and waste materials. Always check the vice position before starting your work.

Using Inappropriate Clamping Methods

Using the wrong clamps or tightening too loosely causes the vice to move. This leads to unsafe drilling and poor precision. Choose clamps designed for drill presses and tighten them firmly. Loose or weak clamping is a common cause of accidents.

Neglecting Vice Wear And Tear

Over time, vices wear out and lose grip strength. Rust, cracks, or bent parts reduce safety and accuracy. Inspect your vice regularly and replace worn parts. Do not ignore signs of damage or the vice may fail during use.

Enhancing Efficiency With Accessories

Using the right accessories can make holding a drill press vice easier and faster. Accessories improve safety and precision. They help keep the workpiece steady. This reduces errors and saves time. Small tools can make a big difference in your work.

Choosing the right accessories depends on the type of work and materials. These tools help you hold the vice firmly and reduce damage to the workpiece. They also allow quick adjustments for repeated tasks. Efficiency grows with the right setup.

Using Soft Jaws And Pads

Soft jaws protect delicate materials from scratches and dents. They fit over the metal jaws of your vice. Made from rubber, plastic, or wood, they add a cushion layer. This prevents damage to soft or finished surfaces. Soft jaws also improve grip without extra force.

Incorporating Stop Blocks

Stop blocks help place workpieces in the same position repeatedly. They are fixed on the drill press table or vice. This saves time by avoiding re-measuring each time. Stop blocks increase accuracy in drilling multiple pieces. They make repetitive tasks faster and easier.

Employing Quick-release Mechanisms

Quick-release mechanisms speed up the clamping and unclamping process. They allow fast adjustments without using tools. This is useful for projects with many different sizes. Quick-release saves effort and reduces downtime. It keeps your workflow smooth and steady.

Credit: www.printables.com

Frequently Asked Questions

How Do I Secure A Drill Press Vice Properly?

To secure a drill press vice, place it on the drill press table. Align it with the drill bit. Use bolts or clamps to fasten it tightly. Ensure the vice is stable to prevent movement during drilling.

What Tools Are Needed To Hold A Drill Press Vice?

You need bolts, nuts, washers, and a wrench to hold the vice. Clamps can also be used for quick setups. These tools ensure the vice stays firmly fixed on the drill press table.

Can I Use Clamps Instead Of Bolts For The Vice?

Yes, clamps can temporarily hold the vice on the drill press. They allow quick adjustments and removal. However, bolts provide a more secure and stable hold for precise drilling.

How To Align The Drill Press Vice With The Drill Bit?

Place the vice on the table and loosely secure it. Lower the drill bit to the vice jaws. Adjust the vice position until the bit is centered. Tighten the bolts or clamps to lock the vice in place.

Conclusion

Holding a drill press vice correctly keeps your work safe and steady. Tighten the vice securely to avoid movement during drilling. Always check the alignment before starting the machine. Use proper clamps if needed for extra support. Taking these steps helps you drill more accurately and safely.

Practice often to feel confident using the drill press vice. Small efforts lead to better results and less risk. Stay careful and focused every time you work. That’s how you get the best from your drill press vice.