Are you struggling to get the perfect speed on your drill press? Knowing how to adjust the speed correctly can save you time, improve your results, and protect your tools.

Whether you’re working with wood, metal, or plastic, the right speed makes all the difference. You’ll discover simple steps to change your drill press speed quickly and safely. Keep reading to master this skill and take your projects to the next level.

Credit: www.reddit.com

Drill Press Speed Basics

Understanding drill press speed is key to safe and effective drilling. Different materials and drill bit sizes need different speeds. Choosing the right speed helps you drill clean holes and avoid damage. This section explains the basics you need to know about drill press speed.

Why Speed Matters

Speed affects how well your drill cuts through material. Too fast can burn the bit or material. Too slow can cause rough holes or broken bits. The right speed keeps the drill bit sharp longer. It also makes your work easier and safer.

Common Speed Settings

Drill presses usually have multiple speed settings. Low speeds are good for hard materials like metal. High speeds work best for soft materials like wood or plastic. Medium speeds fit many general tasks. Always check the drill bit and material guide for best speed.

Credit: www.homemadetools.net

Types Of Drill Presses

Drill presses come in different types. Each type has a different way to change speed. Knowing these types helps you work better and safer. Two common types are belt-driven and variable speed models. Both have their own ways to adjust speed.

Belt-driven Models

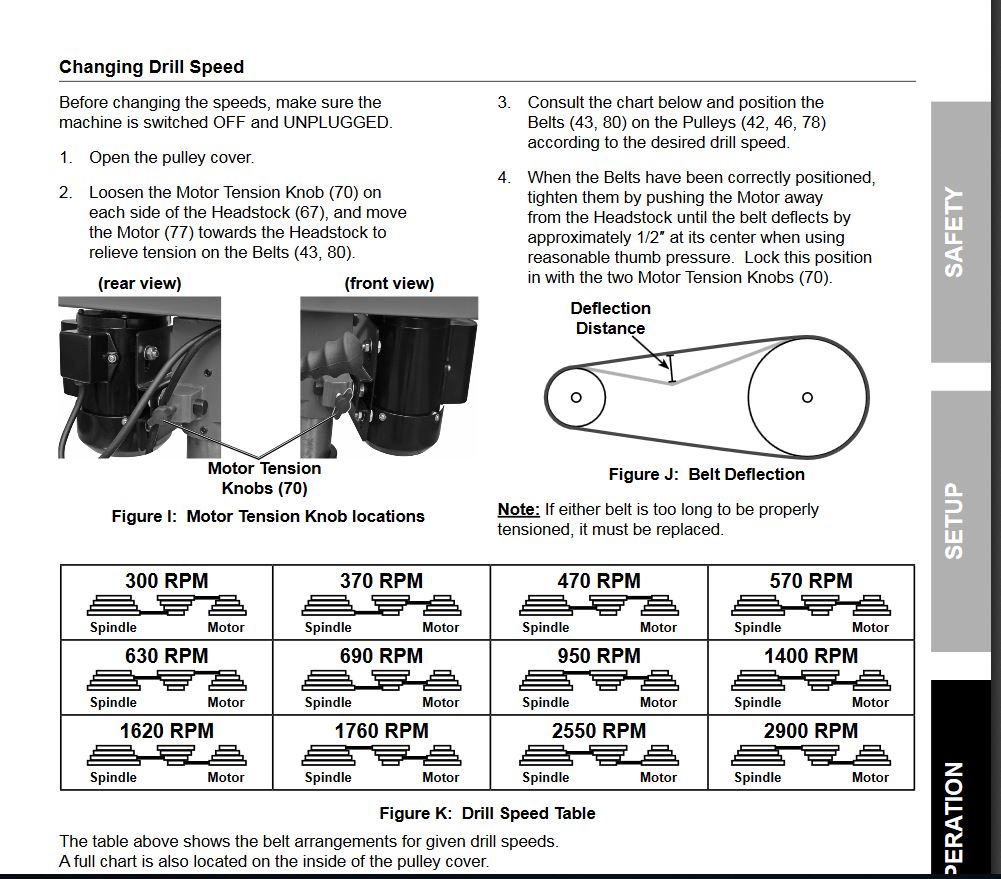

Belt-driven drill presses use belts and pulleys. You change speed by moving the belt to different pulleys. This changes the rotation speed of the drill bit. It needs manual effort to shift the belt. Usually, you stop the drill press first. Then, open the cover and move the belt. This method is simple but takes more time.

Variable Speed Models

Variable speed drill presses use a motor with adjustable speed. You change speed using a dial or lever on the machine. This allows smooth and quick speed changes. No need to stop the drill press. It is easy to adjust speed while working. These models are good for projects needing different speeds fast.

Adjusting Speed On Belt-driven Drill Press

Adjusting the speed on a belt-driven drill press helps match the tool to your task. Different materials need different speeds for clean, safe drilling. Understanding how to change the speed improves your work quality and tool life.

Locating The Belt And Pulleys

First, open the drill press cover to find the belt and pulleys. The belt connects two pulleys—one on the motor, one on the spindle. These pulleys have steps of different sizes to change speed. The belt usually sits on the outer edges of the pulleys.

Changing Pulley Positions

To change speed, move the belt to different pulley steps. Larger pulley on the motor and smaller on the spindle means slower speed. Smaller pulley on the motor and larger on the spindle means faster speed. Use both hands to carefully slide the belt off and onto the new steps.

Ensuring Proper Tension

After moving the belt, check its tension. The belt should be tight but not too hard to stretch. Too loose and the belt slips, causing poor speed and wear. Tighten the motor mount or adjust the belt guide to get the right tension. Proper tension keeps the drill press running smoothly.

Adjusting Speed On Variable Speed Drill Press

Adjusting speed on a variable speed drill press lets you work with different materials easily. You can change speed without stopping the machine. This saves time and helps you get better results. Different materials need different speeds for clean, smooth holes. Variable speed drill presses offer control and flexibility.

Using The Speed Control Dial

The speed control dial is the most common way to adjust speed. Turn the dial clockwise to increase speed. Turn it counterclockwise to lower speed. The dial usually has numbers or marks to show speed levels. Start slow when drilling hard materials. Adjust the dial slowly to find the best speed. The dial gives smooth and steady speed changes.

Digital Speed Settings

Some drill presses have digital speed controls. These allow precise speed adjustments using buttons or a touchscreen. You can set the exact speed you want. The digital display shows the current speed clearly. This helps to keep speed constant during work. Digital controls often have memory to save favorite speeds. This feature speeds up your workflow.

Tips For Optimal Speed Selection

Choosing the right speed on a drill press is key to getting good results. Proper speed helps you drill clean holes without damaging the material or tool. Use these tips for better speed selection and safer work.

Material Considerations

Different materials need different speeds. Soft materials like wood work well at higher speeds. Hard materials like metal require slower speeds. Adjust the speed to match the material hardness. This prevents damage and ensures smooth drilling.

Bit Size And Type

Bigger drill bits need slower speeds. Small bits can spin faster safely. The type of bit also matters. For example, carbide bits need slower speeds than high-speed steel bits. Check the bit specifications for the best speed range.

Avoiding Overheating

Overheating can ruin bits and materials. Use the right speed to keep heat low. Apply light pressure and keep the drill bit cool. Take breaks to let the bit cool down during long jobs. This extends the tool life and keeps work clean.

Credit: www.youtube.com

Safety Precautions During Adjustment

Adjusting the speed on a drill press needs care and attention. Safety is very important to avoid accidents. Follow key precautions to protect yourself and your tools. Small steps can prevent big problems.

Power Off Before Changes

Always turn the drill press off before adjusting the speed. Unplug the machine if possible. This stops the drill from starting by mistake. Moving parts can cause serious injury if the power is on. Check that the machine is fully stopped before touching any controls.

Proper Handling Techniques

Use both hands when adjusting speed controls. Hold tools firmly to avoid slips. Do not force parts that feel stuck. Use the correct tools for adjustments. Keep your fingers away from belts and pulleys. Wear safety glasses to protect your eyes from dust or debris. Clear the area around the drill press before starting work.

Frequently Asked Questions

How Do I Change The Speed On A Drill Press?

To change speed, adjust the belt on the drill press pulleys. Loosen the motor mount, move the belt to a different pulley step, then tighten the mount. This changes the pulley ratio, altering the drill speed for different tasks.

What Is The Ideal Drill Press Speed For Wood?

For wood, use a moderate speed between 1,000 to 3,000 RPM. Slower speeds prevent burning and ensure clean cuts. Always refer to your drill press manual for specific speed recommendations based on the wood type.

Can I Adjust Speed Without Tools On Some Drill Presses?

Yes, some drill presses feature variable speed controls or a dial. This allows easy speed changes without moving belts. Check if your model includes this feature for quick and safe speed adjustments.

Why Is Adjusting Drill Press Speed Important?

Proper speed adjustment ensures clean holes and tool longevity. Different materials require different speeds to prevent damage or overheating. Correct speed improves precision and extends drill bit life.

Conclusion

Adjusting the speed on your drill press improves your work’s quality. Slow speeds work best for large or hard materials. Faster speeds suit smaller or softer materials. Always check the machine’s manual for safety tips. Practice adjusting speed to gain confidence.

Proper speed helps avoid damage to tools and materials. Keep your workspace clean and organized for smooth operation. With regular practice, speed changes will feel easy and natural.