Are you struggling to find the right drill press chuck size for your project? Picking the correct chuck size can save you time, improve your work quality, and prevent damage to your tools.

But how do you know which size fits your drill press perfectly? You’ll discover simple, step-by-step methods to measure and determine your drill press chuck size with confidence. Keep reading, and you’ll never second-guess your choice again.

Types Of Drill Press Chucks

Drill press chucks hold drill bits firmly in place. Different types of chucks fit various needs and machines. Choosing the right type helps improve drilling accuracy and safety.

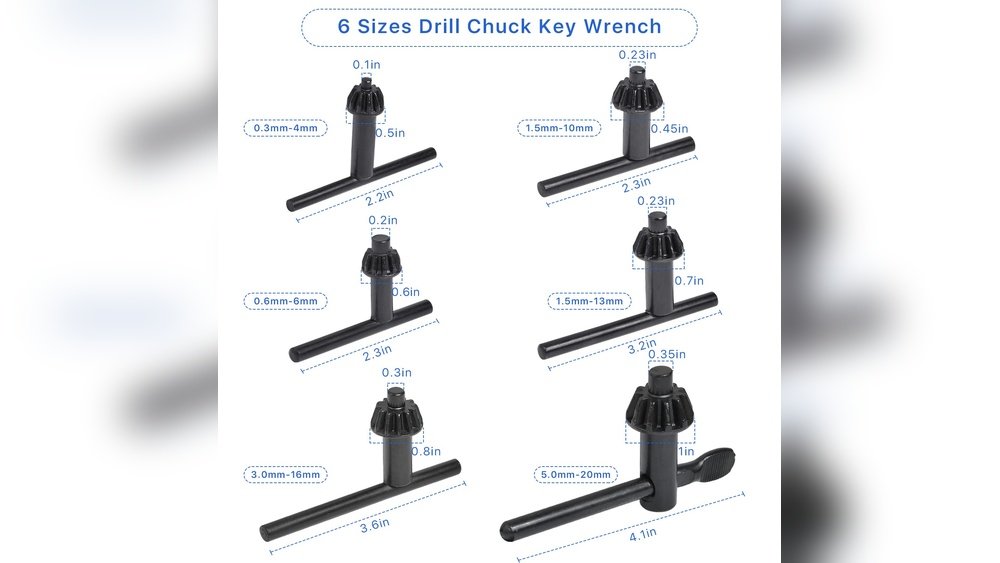

Keyed Chucks

Keyed chucks use a small tool called a chuck key. Turn the key to tighten or loosen the jaws. This type offers strong grip and stability. It works well for heavy drilling tasks. Many older and professional drill presses use keyed chucks.

Keyless Chucks

Keyless chucks allow hand tightening without tools. Twist the chuck sleeve to secure the bit. They offer quick bit changes and convenience. Best for lighter tasks and frequent bit swaps. Some keyless chucks may not hold as tightly as keyed ones.

Jacobs Taper Chucks

Jacobs taper chucks fit directly into the drill press spindle. No jaws or keys are needed. The chuck locks by fitting tightly on a tapered shaft. These chucks provide strong, precise holding power. Common in industrial and heavy-duty drill presses.

Credit: www.martinispa.com

Common Chuck Sizes

Drill press chucks come in different sizes. Each size fits specific drill bits and tasks. Knowing common chuck sizes helps pick the right one for your work. It also ensures better accuracy and safety during drilling.

1/4 Inch Chucks

1/4 inch chucks hold small drill bits. They are best for light jobs like electronics or crafts. These chucks are common in hobbyist drill presses. They fit bits up to 1/4 inch in diameter. Perfect for delicate and detailed drilling.

3/8 Inch Chucks

3/8 inch chucks fit medium-sized bits. They handle tougher materials than 1/4 inch chucks. These chucks work well for general household projects. They support bits up to 3/8 inch wide. Ideal for wood, plastic, and soft metal drilling.

1/2 Inch Chucks

1/2 inch chucks hold large drill bits. They are common in heavy-duty drill presses. These chucks suit thick wood and metal drilling. They accept bits up to 1/2 inch in diameter. Great for construction and industrial work.

Tools Needed For Measurement

Measuring your drill press chuck size requires the right tools. Accurate tools help you find the exact chuck size without guessing. Using proper measuring tools saves time and prevents errors. Here are the most common tools used for this task.

Calipers

Calipers give precise measurements for small and large objects. They can measure inside, outside, and depth dimensions. Digital calipers show easy-to-read numbers on a screen. Manual calipers have a sliding scale for reading measurements. Use calipers to measure the chuck diameter accurately.

Rulers

Rulers are simple and easy to use for basic measurements. Use a metal ruler for better accuracy than plastic ones. Align the ruler carefully to the chuck edge. Rulers work best for rough size estimates or larger chucks.

Measuring Tape

Measuring tape is flexible and useful for round objects. It wraps around the chuck to measure circumference. Use the tape to check the outer size of the chuck. Measuring tapes come in metal or fabric types for different needs.

Credit: makerspaces.northeastern.edu

Measuring The Chuck Diameter

Measuring the chuck diameter is a key step to find the right drill press chuck size. It helps you match the chuck to your drill press or the drill bit. Getting the size right ensures safe and accurate drilling. This section explains simple ways to measure the chuck diameter correctly.

Measuring The Outer Diameter

Use a ruler or caliper to measure the outside edge of the chuck. Place the tool across the widest part of the chuck body. This shows the outer diameter in millimeters or inches. Write down this measurement. It gives a clear idea of the chuck size.

Checking The Jaw Opening

The jaws hold the drill bit in place. Measure the jaw opening by fully opening the jaws. Use a ruler to find the distance between the inside edges of the jaws. This tells you the maximum drill bit size the chuck can hold. Note this measurement carefully.

Measuring The Shank Size

The shank connects the chuck to the drill press. Measure the shank diameter with a caliper or ruler. This size must fit the drill press spindle. Record the shank size in millimeters or inches. Matching the shank size avoids fitting problems later.

Identifying The Taper Size

The taper size of a drill press chuck is crucial for proper fit and function. It determines how the chuck fits into the spindle. Correct identification prevents damage and ensures safety during drilling. Tapers come in standard types that vary by shape and size.

Measuring the taper can be tricky without the right knowledge. Focus on the shape and markings on the chuck or spindle. Use simple tools like calipers for accurate measurement. Knowing the taper type helps choose the right accessories and replacements.

Morse Taper Identification

The Morse taper is common in many drill presses. It has a smooth, slightly conical shape. This taper is self-holding, meaning it tightens under pressure. It usually has a number stamped on the spindle, such as MT1, MT2, or MT3. The higher the number, the larger the taper.

Measure the small end diameter and the length of the taper. Compare these to standard Morse taper charts. The taper angle is about 1.49 degrees per side. This gradual angle helps the chuck stay firm without extra tools.

Jt (jacobs Taper) Identification

The Jacobs taper is another popular type, mainly for drill chucks. It has a slightly different angle and a flat end with a tang. This tang fits into a slot to prevent the chuck from spinning. JT sizes are usually labeled JT0, JT1, JT2, and so on.

Check the diameter at the widest part of the taper. Measure the length from the flat end to the narrow tip. Jacobs taper is less tapered than Morse, with about a 3-degree angle per side. Identifying the tang shape and size helps confirm the JT taper type.

Credit: emproservis.com

Matching Chuck Size To Drill Press

Matching the chuck size to your drill press is crucial for safe and accurate drilling. The chuck must fit perfectly to hold drill bits firmly. A wrong size can cause wobbling or damage to the tool. Understanding how to match the chuck helps you use your drill press better and avoid problems.

Consulting Manufacturer Specifications

Start by checking the drill press manual or manufacturer’s website. They usually list the correct chuck size for each model. This information includes the chuck diameter and the type of spindle taper. Using the recommended size ensures the chuck fits securely and works well.

Some manufacturers also suggest specific brands or models of chucks. Follow these guidelines to maintain your drill press’s warranty. If you cannot find this information, contact customer support for help.

Compatibility Tips

Measure the spindle diameter to verify chuck compatibility. Use a caliper for an accurate measurement. Compare this size with the chuck’s mounting hole. The two must match closely to avoid loose fitting.

Choose a chuck that suits your drill bit size range. Larger drill bits need bigger chucks for better grip. Also, consider the chuck type—keyed or keyless—based on your needs.

Check for any adapter or sleeve requirements. Some drill presses need these to fit certain chucks. Using the right adapter prevents damage and improves performance.

Replacing Or Upgrading Your Chuck

Replacing or upgrading your drill press chuck can improve your machine’s performance. A new chuck offers better grip and precision. It also allows you to use different drill bit sizes. Knowing how to remove and install a chuck makes the process easy and safe.

Removing The Old Chuck

First, unplug the drill press for safety. Open the chuck jaws wide to release the drill bit. Use a chuck key to loosen the chuck by turning it counterclockwise. If the chuck is stuck, tap it gently with a rubber mallet. Some models have a retaining screw inside the chuck. Remove this screw with a screwdriver before taking the chuck off. Pull the chuck straight off the spindle once it is loose.

Installing A New Chuck

Clean the spindle threads and taper before installing the new chuck. Align the new chuck with the spindle carefully. Push the chuck onto the spindle firmly. Tighten the chuck by hand, then use the chuck key to secure it. If there is a retaining screw, insert and tighten it. Test the new chuck by running the drill press at low speed. Make sure the chuck holds drill bits tightly and spins smoothly.

Common Mistakes To Avoid

Choosing the right drill press chuck size is important for safety and tool performance. Many people make simple mistakes that cause problems later. Avoiding these errors saves time and money. Learn about common mistakes to avoid when measuring and selecting your chuck size.

Incorrect Measurements

Measuring the drill press chuck incorrectly is a frequent error. Using the wrong tools or methods leads to wrong sizes. Always use a caliper or precise ruler for accurate results. Measure the chuck diameter across the widest part. Double-check your numbers before buying a new chuck.

Guessing or estimating size can cause the chuck not to fit. This mistake wastes money and effort. Take your time and measure carefully for the best fit.

Ignoring Taper Types

Taper type is key to matching your chuck to the drill press spindle. Different machines use different taper styles like Jacobs or Morse. Not checking the taper type can cause compatibility problems. The chuck may not fit or hold securely.

Identify the spindle taper before choosing the chuck. Look at the drill press manual or spindle markings. Knowing the taper ensures you pick the right chuck for your tool.

Frequently Asked Questions

What Is A Drill Press Chuck Size?

Drill press chuck size refers to the maximum drill bit diameter the chuck can hold. It determines the drill’s capacity and compatibility with various bit sizes.

How Do I Measure My Drill Press Chuck Size?

To measure, use a ruler or caliper. Measure the diameter of the chuck’s opening across the widest part. This gives you the chuck size in inches or millimeters.

Why Is Knowing Drill Press Chuck Size Important?

Knowing the chuck size ensures you select the correct drill bits. It prevents using incompatible bits that can cause damage or reduce drilling accuracy and efficiency.

Can I Use Different Size Drill Bits With One Chuck?

Yes, within the chuck’s size range. For example, a ½-inch chuck can hold bits smaller or equal to ½ inch, but not larger ones.

Conclusion

Knowing the drill press chuck size helps you choose the right drill bits. Measure carefully using simple tools like a ruler or caliper. Understanding this size improves your work accuracy and safety. It saves time by preventing wrong purchases. Keep the chuck size info handy for future projects.

Small steps lead to better results. Drill smart, drill safe.