Have you ever faced the frustration of a seized bolt that just won’t budge? You’re not alone.

When a bolt is stuck tight, it can bring your entire project to a halt. But don’t worry—there’s a way to fix this without damaging your tools or the material around it. In this guide, you’ll learn step-by-step how to drill out a seized bolt safely and effectively.

By the end, you’ll have the confidence to tackle this common problem and keep your work moving forward. Keep reading—you’re about to master a skill that every DIYer and professional needs.

Credit: www.reddit.com

Reasons For Bolt Seizure

Bolt seizure happens when a bolt becomes stuck and hard to remove. Understanding the reasons helps prevent damage and saves time. Several factors cause bolts to seize and require drilling out. Knowing these reasons makes the repair process easier and safer.

Common Causes

Bolt seizure often starts with dirt or debris in the threads. Dust, metal shavings, or paint can block smooth movement. Using the wrong tools or poor fitting can damage threads. This damage makes the bolt harder to turn and remove. Lack of lubrication also increases friction and risk of seizure.

Effects Of Corrosion

Corrosion is a major cause of bolt seizure. Water and chemicals cause rust to form on metal surfaces. Rust expands and locks the bolt tightly in place. Over time, corrosion eats away at the metal threads. This weakens the bolt and makes removal difficult. Regular inspection and cleaning help reduce corrosion risks.

Impact Of Over-tightening

Over-tightening a bolt increases pressure on the threads. This pressure causes the metal to deform or strip. Stripped threads reduce grip and can cause the bolt to seize. Over-tightening can also crack or break the bolt head. Using a torque wrench helps apply the correct tightness. Proper tightening avoids future seizure problems.

Credit: www.madelectrical.com

Tools Needed

Drilling out a seized bolt requires the right tools. Using proper tools saves time and prevents damage. Prepare all tools before starting the job.

Basic Hand Tools

Start with common hand tools. A wrench or socket set helps remove loose parts. A center punch marks the bolt’s center for accurate drilling. A hammer is needed to tap the punch. These tools form the foundation for the job.

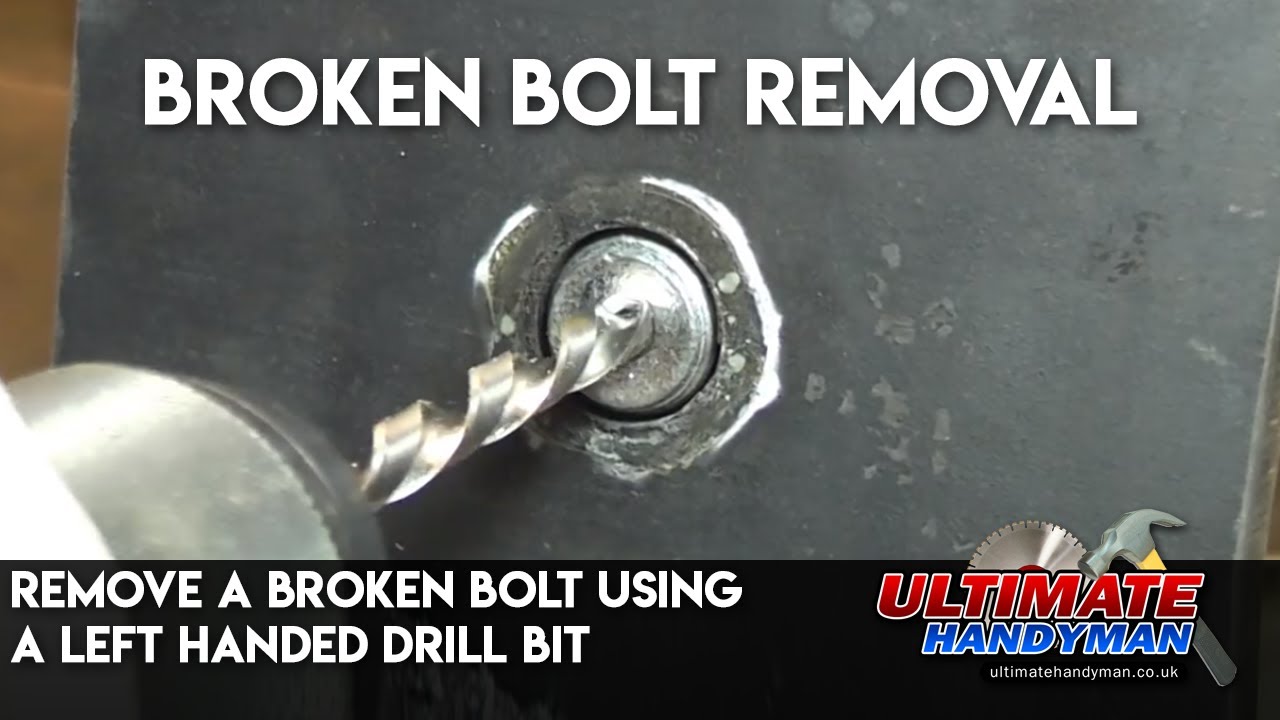

Specialized Drill Bits

Use drill bits made for metal work. High-speed steel (HSS) bits cut through bolts effectively. Left-handed drill bits can help loosen seized bolts. An extractor bit set is useful for removing broken bolts. Pick the right size for precision.

Safety Equipment

Protect yourself during drilling. Safety glasses shield your eyes from metal shards. Gloves protect your hands from sharp edges and heat. Ear protection reduces noise from the drill. Wear clothes that cover your skin fully.

Preparation Steps

Preparing to drill out a seized bolt is a key step. Proper preparation makes the job easier and safer. It helps avoid damage to tools and materials. Follow these simple steps to get ready.

Cleaning The Area

Remove dirt, grease, and rust around the bolt. Use a wire brush or cloth for cleaning. A clean area helps the drill bit grip better. It also prevents debris from interfering with the process.

Applying Penetrating Oil

Apply a good amount of penetrating oil to the bolt. Let it soak for at least 10-15 minutes. The oil helps loosen rust and corrosion. This step reduces the force needed to drill out the bolt.

Setting Up The Workspace

Arrange your tools within easy reach. Make sure the work surface is stable and well-lit. Use clamps to hold the workpiece steady if possible. Safety glasses and gloves protect you from metal shards.

Credit: www.youtube.com

Drilling Techniques

Drilling out a seized bolt needs careful technique to avoid damage. Using the right method helps remove the bolt safely and quickly. This section covers key drilling tips that improve success and protect your tools and work area.

Choosing The Right Drill Bit Size

Select a drill bit slightly smaller than the bolt shaft. This helps avoid cutting into the surrounding material. Using a bit that is too large can damage the bolt hole and make removal harder. A smaller bit creates a pilot hole that guides the drill and reduces slipping.

Drilling At Low Speed

Use low drill speed to keep control and prevent overheating. High speeds can break the drill bit or damage the bolt. Slow drilling allows the bit to cut steadily and reduces friction. Apply steady pressure without forcing the drill to keep the hole straight.

Avoiding Damage To Surroundings

Protect nearby surfaces by covering them with tape or a shield. Keep the drill bit centered to avoid slipping onto other parts. Use cutting oil to cool the bit and reduce wear. Take breaks if the bit gets hot. This prevents damage to both the tool and the workpiece.

Using Extractors

Using extractors is a common way to remove a seized bolt. These tools grip the bolt tightly and help turn it out. Extractors come in different types and sizes. Choosing the right one makes the job easier. Proper insertion is key to avoid breaking the extractor or bolt. Patience and care lead to a smooth removal.

Types Of Extractors

There are two main types of extractors. The first is the spiral flute extractor. It has a tapered, twisted design that bites into the bolt. The second is the straight flute extractor. It uses a simple straight design for easier removal of soft metals. Spiral extractors work best for strong bolts. Straight extractors suit weaker bolts or soft metals.

Proper Insertion Methods

Start by drilling a small hole in the center of the bolt. The hole must be straight and deep enough for the extractor. Insert the extractor gently into the hole. Tap it lightly with a hammer to set it in place. Avoid forcing the extractor to prevent breaking it. Turn the extractor slowly to grip the bolt tightly.

Removing The Bolt

Use a wrench or tap handle on the extractor to turn it counterclockwise. The extractor will bite and start to turn the seized bolt. Keep steady pressure and turn slowly. If the bolt does not move, stop and try again later. Removing a seized bolt needs patience and steady force. Once the bolt starts moving, keep turning until it comes out.

Alternative Methods

Sometimes, the usual methods to remove a seized bolt do not work. Alternative methods can help in tough situations. These techniques use different ways to loosen or remove the bolt without breaking tools or damaging parts. Each method has its own advantages and suits different scenarios.

Heat Application

Applying heat can expand the metal around the bolt. This expansion helps break the rust or corrosion holding the bolt tight. Use a heat gun or small torch carefully. Heat the bolt evenly for a few minutes. Avoid heating nearby plastic or rubber parts. After heating, try to turn the bolt with a wrench. Heat loosens bolts stuck from rust or old paint.

Tapping And Vibrating

Tapping the bolt gently can help shake loose rust or debris. Use a hammer and tap around the bolt head. Do not hit too hard to avoid damage. Vibrations from tapping can break the bond between the bolt and its hole. After tapping, try turning the bolt with a socket or wrench. This method works best for bolts stuck in metal parts.

Cutting The Bolt

Cutting the bolt is a last option when other methods fail. Use a rotary tool or hacksaw to cut a slot in the bolt head. This slot allows a flathead screwdriver to grip. You can also cut off the bolt head completely to remove the remaining part. Be careful to avoid cutting surrounding parts. Cutting is useful for bolts that cannot be unscrewed by normal means.

Post-removal Tips

After removing a seized bolt, some important steps follow. These post-removal tips help keep your project safe and working well. Taking care of the area ensures smooth repairs and stops future problems. Focus on cleaning, checking, and prevention for the best results.

Cleaning The Threads

Remove any dirt and rust from the bolt hole and threads. Use a wire brush or thread chaser to clean gently. Clear threads allow new bolts to fit easily. Clean threads prevent damage and ensure a strong hold.

Inspecting For Damage

Check the threads and surrounding metal for cracks or wear. Look closely at the hole and bolt area. Damaged threads can cause bolts to loosen or break. Replace or repair damaged parts before reassembling.

Preventing Future Seizures

Apply anti-seize lubricant or grease on new bolts before installation. Use the correct bolt size and torque settings. Avoid over-tightening bolts to reduce stress. These steps help bolts last longer and stay easy to remove.

Frequently Asked Questions

How Do You Safely Drill Out A Seized Bolt?

To safely drill out a seized bolt, first secure the workpiece. Use a center punch to mark the bolt center. Start with a small drill bit and gradually increase size. Apply steady pressure and coolant to avoid overheating. Always wear safety goggles and gloves.

What Tools Are Needed To Drill Out A Seized Bolt?

You need a drill, drill bits, center punch, penetrating oil, and safety gear. A bolt extractor set may help remove the bolt after drilling. Use a lubricant to ease drilling and prevent damage. Proper tools improve success and safety.

How Can Penetrating Oil Help With Seized Bolts?

Penetrating oil loosens rust and corrosion around the bolt threads. Apply it generously and let it soak for at least 15 minutes. This makes drilling easier and reduces the risk of bolt breakage. It also protects your drill bits.

Can Drilling Damage The Surrounding Material?

Yes, drilling can damage nearby material if not done carefully. Use the correct drill bit size and low speed to minimize damage. Secure the workpiece firmly to avoid slipping. Take your time to ensure precision and avoid costly repairs.

Conclusion

Drilling out a seized bolt takes patience and the right tools. Start slow and keep the drill steady. Use the correct drill bit size to avoid damage. Take breaks to prevent overheating. Safety matters—wear protective gear. Practice this method on old bolts first.

With care, you can remove stuck bolts without extra cost or stress. Keep calm and work carefully. This skill saves time and money in repairs. Try it step-by-step, and you will succeed.