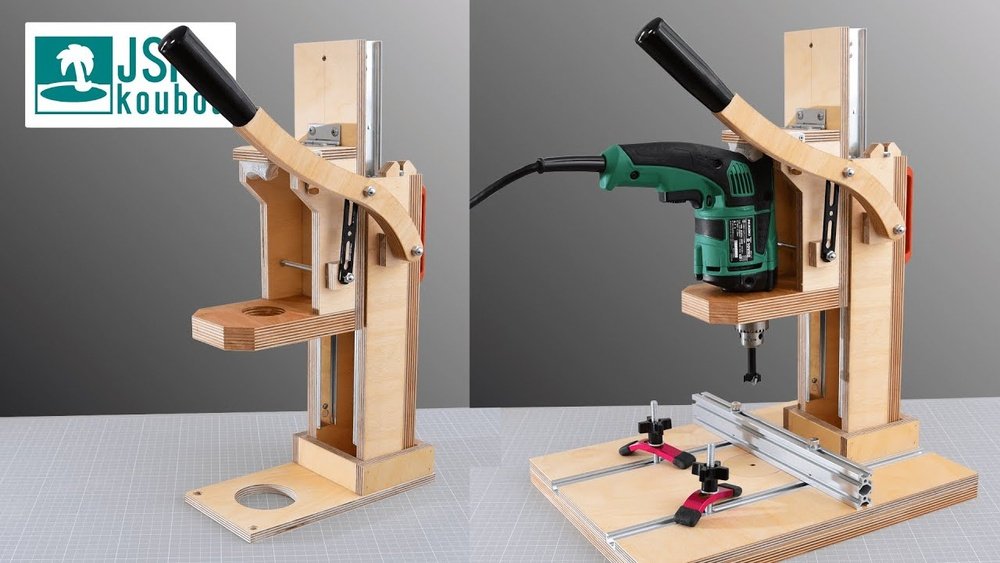

Are you ready to build your very own drill press machine and take your DIY projects to the next level? Imagine having a powerful tool right at your fingertips, one that can drill precise holes with ease and accuracy.

Whether you’re a hobbyist or a beginner, making your own drill press can save you money and give you complete control over your work. In this guide, you’ll discover simple steps and insider tips that make the process straightforward and fun.

Keep reading, and soon you’ll have a reliable drill press that’s built by you, for you.

Credit: www.instructables.com

Essential Tools And Materials

Building a drill press machine requires specific tools and materials. Having the right items helps the process go smoothly. It also ensures the machine works well and lasts a long time.

This section lists the essential tools and materials you need. Prepare these before starting your project. It will save time and reduce errors.

Required Tools

- Electric drill or drill motor for power

- Metal saw or hacksaw to cut metal parts

- Welding machine or strong metal adhesive

- Measuring tape or ruler for accuracy

- Clamps to hold parts steady

- Wrenches and screwdrivers for assembly

- Grinding tool to smooth edges

- Safety gear: gloves, goggles, and ear protection

Materials Checklist

- Steel or iron rods for frame and support

- Metal sheet for the base and table

- Drill chuck to hold drill bits

- Electric motor compatible with drill speed

- Bearings for smooth rotation

- Bolts, nuts, and washers for fastening

- Springs for tension control

- Paint or rust protection coating

Credit: hackaday.com

Choosing The Right Motor

Choosing the right motor for your drill press machine is a key step. The motor controls the speed and power of the drill. Picking the correct motor ensures smooth operation and longer machine life. This section explains motor types and power needs.

Motor Types

There are mainly two types of motors used in drill presses: AC and DC motors.

AC motors run on household electricity and are common in many machines. They are simple and reliable for most drilling tasks.

DC motors offer better speed control and efficiency. They are often used in advanced or portable drill presses.

Choosing between AC and DC depends on your drilling needs and budget.

Power Requirements

Power is measured in horsepower (HP) or watts. A drill press needs enough power to handle the materials you drill.

Light tasks like drilling wood need a motor with about 1/3 to 1/2 HP.

For harder materials, choose a motor with 3/4 HP or more. This prevents motor strain and overheating.

Check the motor speed too. Variable speed motors offer more control for different jobs.

Building The Base

The base is the foundation of a drill press machine. It must be strong and stable to support all parts. A good base reduces vibrations during drilling. This makes your work safer and more precise. Building the base carefully ensures your drill press lasts longer and works better.

Material Selection

Choose materials that are heavy and durable. Steel and cast iron work well for stability. Wood can be used but it may not last as long. Avoid light metals because they may vibrate too much. The base should resist wear and hold the machine firmly in place.

Assembly Process

Start by cutting the base material to the right size. Smooth all edges to prevent injury. Drill holes to attach the column and motor securely. Use strong bolts and nuts to hold parts tight. Check that the base is level before tightening all fasteners. A flat base prevents wobbling during use.

Constructing The Column

The column is the backbone of a drill press machine. It holds the drill head and allows smooth vertical movement. A strong column keeps the machine steady and accurate during drilling. Building the column correctly ensures the drill press works well and lasts long.

Dimensions And Design

Choose a metal pipe or steel tube for the column. The diameter should be about 2 to 3 inches. Height depends on your workspace and drill size, usually 24 to 36 inches. The column must be thick enough to resist bending. A round shape helps the drill head slide up and down easily. Smooth the surface to reduce friction and wear. Make sure the column is straight to avoid wobbling during use.

Mounting Techniques

Secure the column firmly to the base for stability. Use a strong metal plate and bolts to fix the column. Drill holes in the base and column for tight fitting bolts. Check that the column is vertical using a level tool. Weld the base plate if possible for extra strength. Attach the drill head clamp so it can slide smoothly along the column. Tighten clamps well to hold the drill head in place while working.

Designing The Drill Head

The drill head is the core part of a drill press machine. It holds the drill bit and controls its movement. A well-designed drill head ensures accurate drilling and smooth operation. Careful planning of its components is essential for good performance.

Focus on the spindle, chuck, and speed control. These parts affect how well the machine works. Each must be chosen and placed with care. Let’s explore these components in detail.

Spindle And Chuck Setup

The spindle is the rotating shaft that holds the chuck. It must be strong and straight to avoid wobbling. Use steel or hardened metal for durability. The spindle fits into bearings for smooth rotation.

The chuck grips the drill bit. Choose a chuck that matches the drill bit size. Keyed chucks offer a tighter grip, while keyless chucks provide quick bit changes. Secure the chuck firmly to the spindle for safety.

Speed Control Mechanism

Speed control adjusts how fast the drill bit spins. Different materials need different speeds. Use a pulley system or variable speed motor to change speed easily.

A simple belt and pulley setup can offer multiple speeds. Changing the belt position changes speed. For more control, use an electronic speed controller. This lets you adjust speed smoothly without stopping the machine.

Assembling The Table

Assembling the table is a key step in building your drill press machine. The table holds the material steady during drilling. It must be strong and easy to adjust. Proper assembly ensures safety and accuracy. Let’s explore two important features of the drill press table.

Adjustable Height

The table’s height needs to change for different projects. You can raise or lower it using a simple crank or lever. This lets you drill large or small items. Adjusting height helps you work comfortably and safely. Make sure the height locks firmly in place. A stable table prevents mistakes and accidents.

Rotation Features

The table should rotate to reach different angles. This rotation makes angled drilling easier. Usually, the table turns smoothly around a center point. Locking mechanisms keep the table fixed at the right angle. Rotating tables add flexibility and precision to your work. Check that the rotation moves freely but holds steady.

Electrical Wiring And Safety

Electrical wiring is a key part of building a drill press machine. It connects the motor and controls power flow. Proper wiring ensures the machine runs smoothly and safely. Safety must be the top priority during this process.

Careful wiring stops electrical faults and reduces risk of shocks. Using the right tools and materials is important. Follow clear steps to connect wires correctly. This helps protect both the machine and the user.

Wiring The Motor

Start by identifying the motor’s power requirements. Check the voltage and current ratings on the motor label. Use wires that can handle this power safely. Connect the motor wires to the power supply terminals. Secure connections with wire nuts or terminal blocks. Avoid loose or exposed wires to prevent shorts. Use insulated wires to keep the setup safe. Double-check connections before powering the motor on.

Safety Switches

Install safety switches to control the drill press power. Emergency stop buttons allow quick power cut-off. Place switches where they are easy to reach. Use switches with clear ON/OFF markings. Test switches regularly to confirm they work properly. Safety switches reduce the chance of accidents. They add an important layer of protection for users.

Testing And Calibration

Testing and calibration are key steps after building your drill press machine. These processes ensure the machine works correctly and safely. Proper testing helps avoid mistakes during drilling and extends the machine’s life.

Calibration makes sure the drill press operates at the right speed and alignment. It also confirms the accuracy of drilling holes. Without careful calibration, the machine might produce uneven or wrong-sized holes.

Alignment Checks

Start with alignment checks to verify the drill bit is straight. Use a square tool to check if the bit is perpendicular to the base. Adjust the spindle or table until the drill bit lines up perfectly. Poor alignment causes crooked holes and damages the workpiece. Repeat the check after every adjustment for best results.

Speed Testing

Speed testing confirms the drill press runs at correct speeds. Use a tachometer to measure the spindle’s rotations per minute (RPM). Test the machine at all speed settings you plan to use. Ensure the motor runs smoothly without unusual noise or vibration. Correct speed improves drilling quality and protects the drill bit from wear.

Maintenance Tips

Proper maintenance keeps your drill press machine working well for years. It helps avoid breakdowns and costly repairs. Simple steps can improve its life and performance. Focus on key areas to keep the machine smooth and safe.

Lubrication

Lubricate moving parts regularly. Use oil or grease suitable for your drill press. This reduces friction and wear. Pay attention to the spindle, gears, and bearings. Clean old lubricant before adding new. This prevents dirt buildup and damage.

Routine Inspections

Check your drill press often for any issues. Look for loose bolts, worn belts, and cracks. Test the switches and power cords for safety. Tighten or replace parts as needed. Catching problems early saves time and money later.

Credit: www.youtube.com

Frequently Asked Questions

What Materials Are Needed To Make A Drill Press Machine?

You need a motor, drill chuck, spindle, base, column, and table. Additional tools like bolts and switches are essential. Quality materials ensure durability and precision in your drill press machine.

How Do I Assemble A Homemade Drill Press Machine?

Start by fixing the motor to the base, then attach the spindle and drill chuck. Secure the column upright and mount the adjustable table. Ensure all parts are tightly fastened for stability and safety.

What Safety Tips Should I Follow When Using A Drill Press?

Always wear safety goggles and keep hands clear of the drill bit. Use clamps to secure your workpiece. Ensure the machine is turned off before adjustments. Follow these tips to avoid accidents and work efficiently.

Can I Use A Drill Press Machine For Woodworking Projects?

Yes, a drill press is ideal for precise drilling in wood. It provides better control and accuracy than handheld drills. Use appropriate drill bits for different wood types to get clean holes.

Conclusion

Building a drill press machine takes patience and care. Follow each step slowly and check your work often. Using the right tools makes the job easier and safer. This project helps you learn basic mechanical skills. You can use the drill press for many tasks once done.

Keep your workspace clean and organized during the build. Safety should always come first to avoid accidents. Enjoy the process and the feeling of creating something useful. Practice makes perfect, so don’t rush or worry about small mistakes. Your new drill press will be a handy tool at home.