Are you curious about how to drill for oil on land? Whether you’re a beginner or just want to understand the process better, this guide will walk you through the key steps.

Imagine tapping into a valuable resource right beneath your feet. Knowing how to start can save you time, money, and frustration. Keep reading, and you’ll discover simple, practical tips to help you get started with land oil drilling the right way.

Your journey to unlocking underground oil begins here.

Site Selection

Choosing the right site is the first step to drilling for oil on land. The success of drilling depends a lot on where you decide to drill. Careful planning and research help reduce risks and costs. You need to understand the land and what lies below the surface.

Several factors affect site selection. These include the geology, ownership of the land, and environmental rules. Each factor needs attention to make drilling safe and effective.

Geological Surveys

Geological surveys study the earth to find oil deposits. Experts use maps and tools to check the underground layers. They look for rock formations that may hold oil. Seismic surveys send sound waves into the ground. The waves bounce back and reveal hidden structures.

Survey data helps decide the best spots to drill. It reduces the chance of drilling dry wells. Accurate surveys save time and money in the drilling process.

Land Acquisition

Before drilling, securing the land rights is essential. You must get permission from landowners or the government. This process involves legal agreements and contracts. Clear land ownership avoids future disputes.

Check local laws and regulations about land use. Sometimes, multiple parties share land rights. Proper negotiation ensures smooth operations during drilling.

Environmental Considerations

Drilling affects nature and nearby communities. Environmental checks identify sensitive areas like forests or water bodies. Avoiding these zones helps protect wildlife and water quality.

Follow environmental laws to prevent pollution and damage. Plan waste disposal and spill control carefully. Respecting the environment reduces risks and builds trust.

Credit: en.wikipedia.org

Permitting And Regulations

Drilling for oil on land requires careful attention to permits and regulations. These rules protect the environment, workers, and local communities. Following the correct legal steps helps avoid fines and delays.

Obtaining Permits

Start by applying for the necessary permits from local and national authorities. Permits vary by location and project size. Common permits include drilling, environmental, and land use permissions. Submit detailed plans and pay fees to begin the process. Approval may take weeks or months, so plan ahead.

Compliance With Laws

Follow all laws related to land use and environmental protection. Laws control waste disposal, water use, and air emissions. Regular inspections ensure compliance. Failure to comply can result in fines or work stoppages. Keep up to date with changes in regulations. Hire legal experts if needed to navigate complex rules.

Safety Standards

Adhere to strict safety standards to protect workers and the environment. Use proper equipment and train workers thoroughly. Safety plans must cover emergency response and hazard management. Regular safety checks reduce accidents and improve efficiency. Compliance with safety rules also builds trust with the community.

Equipment And Technology

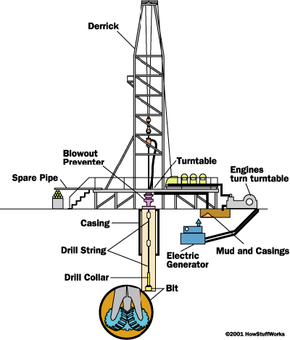

Drilling for oil on land needs the right equipment and technology. The tools must be strong and precise. They help reach deep oil layers safely and quickly. Using the right gear improves success and lowers risks.

Understanding each type of equipment helps plan the drilling process better. This section explains the main tools and systems used in land oil drilling.

Choosing Drilling Rigs

Drilling rigs are large machines that make holes in the ground. They come in many sizes and types. Select a rig based on the land, depth, and oil type. Some rigs move easily for different spots. Others are fixed and powerful for deep drilling. Matching the rig to the job saves time and money.

Drilling Tools

Drilling tools include drill bits, pipes, and pumps. Drill bits cut through rock and soil. They must be hard and sharp. Pipes carry the drill bit and remove debris. Pumps push fluids to cool the drill and bring cuttings up. Choosing tools that fit the soil type and depth is key for smooth drilling.

Monitoring Systems

Monitoring systems track drilling progress and safety. Sensors measure pressure, temperature, and vibrations. Data helps spot problems early. Real-time monitoring prevents accidents and equipment damage. Modern systems also guide the drill to stay on course. These systems make drilling safer and more efficient.

Credit: www.martinispa.com

Preparing The Site

Preparing the site is the first step in drilling for oil on land. This process ensures the area is safe and ready for heavy equipment. Proper preparation helps avoid delays and accidents. It also protects the environment and nearby communities.

Clearing And Leveling

Clear the land of trees, bushes, and rocks. This creates space for drilling machines and workers. Level the ground to make it flat. A flat surface prevents equipment from tipping over. It also makes drilling faster and safer.

Building Access Roads

Construct roads to reach the drilling site. These roads allow trucks and machines to move easily. Use gravel or dirt to build strong roads. Good roads reduce travel time and wear on vehicles. They also help bring supplies and workers to the site.

Setting Up Infrastructure

Install essential facilities like water and power supply. Set up storage areas for fuel and equipment. Build temporary offices and rest areas for workers. Proper infrastructure keeps the site organized. It supports smooth drilling operations and worker safety.

Drilling Process

The drilling process is the core step in finding oil under the land. It involves making a deep hole into the earth to reach oil deposits. This task needs careful planning and skill to avoid problems. Drilling must be done safely and efficiently to protect the environment and workers.

Each stage in drilling has a clear purpose. From choosing the right tools to managing fluids, every detail matters. Understanding these steps helps explain how oil is brought from underground to the surface.

Drilling Techniques

Drilling starts with selecting the best technique for the land and depth. The most common method uses a rotary drill bit that turns to cut through rock. Drill pipes carry the bit down and allow fluids to flow up.

Directional drilling helps reach oil not directly under the drill site. It guides the drill bit to curve and hit targets far below or sideways. This method saves land space and reaches hard places.

Managing Drilling Fluids

Drilling fluids, or mud, cool the drill bit and carry rock bits to the surface. They also keep the hole stable and stop oil or gas from escaping suddenly. The fluid must be the right mix to work well under pressure.

Monitoring fluid quality is crucial. Proper fluid management prevents accidents and helps the drill move smoothly. It also protects the environment by containing harmful materials.

Handling Unexpected Challenges

Drilling can face sudden problems like hitting hard rock or high pressure zones. These issues slow down work and can be dangerous. Quick decisions and proper tools help fix problems fast.

Regular checks and good communication keep the team ready for surprises. Safety rules guide every action to avoid accidents. Being prepared lowers risks and keeps drilling on track.

Well Completion

Well completion is a key step after drilling an oil well. It prepares the well for safe and efficient production. This process ensures the well is sealed and ready to bring oil to the surface. Proper completion protects the environment and improves oil flow.

Casing And Cementing

Casing is a steel pipe placed inside the drilled hole. It holds the well open and prevents collapse. Cement is pumped around the casing to seal the space between the pipe and the rock. This stops fluids from leaking into other layers. Cementing also protects groundwater from contamination.

Installing Production Equipment

After casing, production equipment is set up at the wellhead. This includes valves and pipes to control oil flow. The equipment helps manage pressure and flow rate safely. It also allows for maintenance and monitoring during production.

Testing The Well

Testing checks if the well can produce oil effectively. Pressure tests ensure the casing and equipment hold up under stress. Flow tests measure how much oil or gas comes out. These tests confirm the well is ready for full production.

Safety And Environmental Protection

Drilling for oil on land requires careful attention to safety and the environment. Protecting workers and nature is a top priority. Following strict rules helps avoid accidents and pollution. Responsible practices keep the site safe and clean.

Emergency Preparedness

Always have an emergency plan ready. Train workers to respond quickly to fires or spills. Keep safety gear and first aid kits close. Clear communication helps reduce risks during emergencies. Regular drills prepare the team for real events.

Waste Management

Handle waste materials with care. Store drilling fluids and chemicals safely to prevent leaks. Use proper containers for oil and sludge. Dispose of waste according to local laws. Recycling and reuse reduce environmental harm.

Minimizing Impact

Choose drilling sites carefully to protect wildlife and plants. Limit land clearing to what is necessary. Use technology to reduce noise and dust. Restore the land after drilling ends. Small actions make a big difference for nature.

Post-drilling Activities

After drilling for oil on land, several important activities take place. These post-drilling steps ensure safety, efficiency, and environmental care. Proper handling after drilling helps maintain the site and supports ongoing oil production.

Site Restoration

Site restoration repairs the land affected by drilling. Workers remove equipment and clean the area. Soil is replaced or treated to help plants grow back. Restoring the site reduces environmental damage and protects wildlife habitats.

Production Monitoring

Production monitoring tracks the amount of oil extracted. Sensors and tools measure pressure, flow, and volume. This data helps operators adjust processes for better output. Constant monitoring prevents accidents and keeps operations safe.

Maintenance And Repairs

Maintenance keeps drilling equipment in good condition. Regular checks find issues before they cause problems. Repairs fix leaks, broken parts, and wear. Good maintenance extends equipment life and avoids costly downtime.

Credit: science.howstuffworks.com

Frequently Asked Questions

What Equipment Is Needed To Drill For Oil On Land?

Essential equipment includes a drilling rig, drill bits, casing pipes, mud pumps, and safety gear. These tools enable safe and efficient drilling operations on land.

How Do You Locate Oil Reserves Before Drilling?

Geologists use seismic surveys, magnetic data, and soil sampling to identify potential oil reserves underground before drilling starts.

What Safety Measures Are Important During Land Oil Drilling?

Safety measures include proper training, protective gear, regular equipment checks, and emergency response plans to prevent accidents and ensure worker safety.

How Long Does It Take To Drill An Oil Well On Land?

Drilling an oil well typically takes a few weeks to several months, depending on depth, geology, and technology used.

Conclusion

Drilling for oil on land takes careful planning and hard work. You must choose the right spot and use proper tools. Safety should always come first to avoid accidents. Knowing the basics helps you work more confidently. Keep learning as you go to improve your skills.

Oil drilling can be tough, but patience pays off. Stay focused and follow the steps well. This way, you increase your chances of finding oil.