Have you ever wondered what makes a pneumatic hammer drill so powerful and efficient? If you’re looking to understand how this tool works and why it’s a favorite among professionals, you’re in the right place.

Knowing the inner workings of a pneumatic hammer drill can help you use it better, maintain it properly, and even choose the right model for your needs. Keep reading, and you’ll discover the simple mechanics behind this impressive tool and how it can make your drilling tasks easier and faster.

Basics Of Pneumatic Hammer Drills

Pneumatic hammer drills are powerful tools used in construction and repair work. They use air pressure to create strong hammering action. This action helps drill through tough materials like concrete and stone. Understanding the basics of these drills helps you use them better and choose the right one for your needs.

These tools are different from regular drills because they combine rotation with hammering. This makes drilling faster and easier in hard surfaces. Let’s explore the key parts of pneumatic hammer drills and how they differ from electric drills.

Key Components

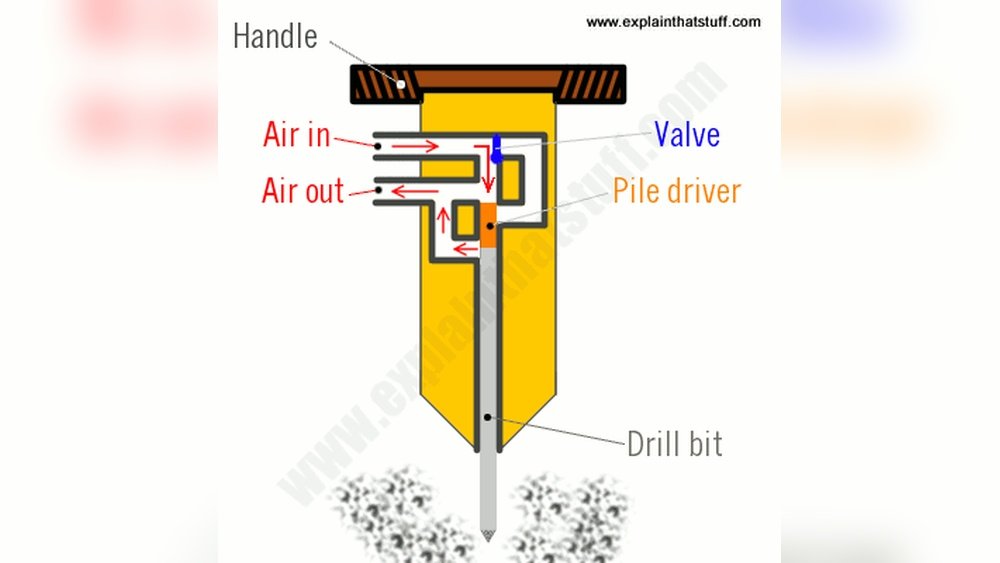

Pneumatic hammer drills have several important parts. The first is the air compressor, which provides the air pressure. Then, the drill body holds the motor and hammer mechanism. Inside, a piston moves back and forth, creating the hammering motion. The drill bit attaches to the chuck and spins to drill holes.

The trigger controls the air flow, starting or stopping the drill. The hammer mechanism hits the drill bit with high force. This pounding action breaks tough materials quickly. All parts work together to deliver strong, fast drilling power.

How It Differs From Electric Drills

Pneumatic hammer drills use compressed air, not electricity. This makes them lighter and easier to handle for long jobs. They also produce less heat, reducing wear on parts. Electric drills rely on electric motors and often have slower hammer action.

Another difference is power source. Pneumatic drills need an air compressor nearby. Electric drills only need a power outlet or battery. Pneumatic models are better for heavy-duty work. Electric drills suit lighter tasks and home use.

Credit: tft-pneumatic.com

Mechanism Behind The Hammer Action

The hammer action in a pneumatic hammer drill is what makes it powerful and effective. This action allows the drill to deliver strong, fast impacts. These impacts help break tough materials like concrete and stone. Understanding the mechanism behind this action shows how the tool works efficiently.

Role Of Compressed Air

Compressed air powers the hammer action in the drill. It enters the tool through a hose connected to an air compressor. The air pressure pushes parts inside the drill to move quickly. This pressure is controlled to create fast, repeated impacts. Without compressed air, the hammer action cannot happen.

Piston Movement Explained

Inside the drill, a piston moves back and forth. The compressed air pushes the piston forward with force. When the piston moves forward, it hits the drill bit. This impact breaks the material. Then, the piston moves back to prepare for the next hit. This quick piston movement creates the hammering effect.

Types Of Pneumatic Hammer Drills

Pneumatic hammer drills come in various types. Each type serves a specific purpose in construction and demolition. Understanding the differences helps choose the right tool for the job.

These tools use compressed air to create powerful hammering action. The hammering breaks hard materials quickly and efficiently. Below are the main types of pneumatic hammer drills.

Chipping Hammers

Chipping hammers are small and lightweight. They work well for removing rust, paint, and small concrete chunks. These hammers deliver rapid, short hammering strokes. This makes them perfect for detailed work and cleaning surfaces.

Jackhammers

Jackhammers are heavy-duty pneumatic drills. They break large concrete slabs, rocks, and pavement. Their strong hammering power makes tough jobs easier. Operators use them in road construction and demolition projects.

Rotary Hammer Drills

Rotary hammer drills combine hammering with rotation. This dual action drills into hard materials like concrete and stone. They are versatile tools for drilling holes and breaking surfaces. These drills are popular in construction and renovation work.

Credit: www.youtube.com

Applications In Construction And Industry

Pneumatic hammer drills find many uses in construction and industry. Their power and efficiency make tough jobs easier. These tools handle hard materials like concrete and metal with ease. They speed up work and reduce manual effort.

Builders and workers rely on pneumatic hammer drills for heavy-duty tasks. The tool’s strong impact helps break and shape materials quickly. This section explores common applications in construction and industry.

Concrete Breaking

Pneumatic hammer drills break concrete efficiently. They chip away old surfaces and prepare areas for new work. The tool’s powerful blows crack concrete faster than manual tools. This saves time during road repairs and building renovations. Workers use it to remove damaged sections easily.

Metalworking Tasks

These drills assist in shaping and cutting metal parts. The hammer action helps punch holes or chip away rust. Metalworkers use pneumatic drills for fast, clean results. The tool handles thick metals that normal drills cannot. It improves precision in metal fabrication jobs.

Demolition Uses

Pneumatic hammer drills are essential in demolition projects. They break down walls, floors, and old structures quickly. The tool’s force breaks materials into manageable pieces. This speeds up cleanup and site preparation. Demolition workers depend on its strength and reliability every day.

Advantages Over Other Drill Types

Pneumatic hammer drills stand out from other drill types in many ways. Their unique design offers clear benefits for various tasks. These benefits make them a popular choice in construction and heavy-duty work.

Power And Efficiency

Pneumatic hammer drills deliver strong and steady power. They use compressed air to create fast, repeated hammering action. This action breaks tough materials like concrete and stone easily. These drills run cooler than electric ones, avoiding overheating. They maintain consistent performance for long work periods. Their efficient power use saves time and energy on jobs.

Durability And Maintenance

Pneumatic hammer drills are built to last in harsh conditions. Their simple, sturdy parts resist wear and tear better than electric drills. They have fewer electrical components that can fail or get damaged. Maintenance is easier and less frequent, reducing downtime. Regular oiling keeps them running smoothly. This durability makes them reliable tools for tough work sites.

Safety Tips For Using Pneumatic Hammer Drills

Using a pneumatic hammer drill can be powerful and efficient. Safety matters a lot with this tool. Knowing the right safety tips helps prevent injuries. It also keeps the work smooth and controlled.

Protective Gear

Always wear safety goggles to protect your eyes from flying debris. Use ear protection to guard against loud noise. Heavy-duty gloves help protect your hands from vibration and sharp edges. Wear a dust mask if you work in dusty areas. Steel-toed boots keep your feet safe from falling objects. Dress in long sleeves and pants to protect your skin.

Proper Handling Techniques

Hold the drill firmly with both hands. Keep a balanced stance to avoid slipping. Start the drill slowly to control the movement. Avoid forcing the tool; let it do the work. Stop immediately if the drill jams or feels unusual. Always disconnect the air supply before changing bits or making adjustments.

Maintenance And Troubleshooting

Maintaining a pneumatic hammer drill keeps it working well and lasts longer. Troubleshooting helps fix small problems before they grow. Regular care avoids costly repairs and downtime.

Knowing common issues and simple care tips ensures smooth operation. This section covers frequent problems and basic maintenance steps.

Common Issues

One common issue is loss of power. It may come from low air pressure or leaks in the hose. Check the connections and air supply first.

The drill might also jam or stop suddenly. Dirt and debris can block the hammer mechanism. Clean the tool regularly to prevent this.

Another problem is unusual noises. Worn parts or lack of lubrication often cause noise. Inspect moving parts and add oil as needed.

Routine Care

Always clean the drill after use. Remove dust and debris from the vents and moving parts. Use a dry cloth or compressed air.

Lubricate the tool regularly. Apply oil to the hammer mechanism and moving parts. This reduces friction and wear.

Check the air hose and fittings. Replace damaged hoses to avoid leaks. Tighten loose connections for steady air flow.

Store the drill in a dry place. Avoid moisture, which can cause rust and damage. Use a protective case if possible.

Credit: www.youtube.com

Frequently Asked Questions

How Does A Pneumatic Hammer Drill Operate?

A pneumatic hammer drill uses compressed air to create rapid hammering action. This helps break or drill through tough materials efficiently. The compressed air drives a piston, which strikes the drill bit repeatedly, enhancing drilling speed and power.

What Are The Main Parts Of A Pneumatic Hammer Drill?

Key parts include the air compressor, piston, drill bit, and trigger mechanism. The compressor supplies air, the piston creates hammering, and the drill bit performs the drilling. The trigger controls airflow and operation.

Why Choose A Pneumatic Hammer Drill Over Electric Ones?

Pneumatic drills offer higher power and durability for heavy-duty tasks. They are lighter, reduce operator fatigue, and work well in wet conditions. Plus, they generate less heat and have longer lifespans.

What Materials Can Pneumatic Hammer Drills Effectively Work On?

They are ideal for concrete, stone, brick, and other hard materials. Their hammering action breaks tough surfaces, making drilling easier. They are commonly used in construction and demolition projects.

Conclusion

A pneumatic hammer drill uses air pressure to power its hammering action. This makes drilling into hard materials easier and faster. The tool combines rotation and impact to break through tough surfaces. It works best with concrete, stone, and metal.

Understanding its simple mechanism helps users choose the right tool. Using it properly improves efficiency and safety on the job. Pneumatic hammer drills remain popular for heavy-duty tasks. They offer strong performance without relying on electricity. Knowing how this tool works aids in better handling and results.