If you want your Milwaukee rotary hammer drill to work smoothly and last longer, greasing it properly is key. You might think this task is complicated, but it’s actually simple once you know the right steps.

By giving your drill the right care, you can avoid costly repairs and keep your tool running like new. In this guide, you’ll learn exactly how to grease your Milwaukee rotary hammer drill quickly and effectively—so you can get back to work without any hassle.

Keep reading to discover the easy way to protect your investment and boost your drill’s performance.

Choosing The Right Grease

Choosing the right grease for your Milwaukee rotary hammer drill is key to keeping it working smoothly. The correct grease reduces friction and heat inside the tool. This prevents damage and extends the drill’s life. Using the wrong grease can cause parts to wear out faster. It can also lead to poor performance. Knowing which grease fits your drill ensures better results and less repair cost.

Types Suitable For Rotary Hammer Drills

Rotary hammer drills need grease that can handle high pressure and heat. Lithium-based grease is a common choice. It sticks well and protects metal parts from rust. Another good option is synthetic grease. It lasts longer and works well in extreme temperatures. Avoid grease that is too thin or oily. This type does not protect moving parts effectively. Always check your drill’s manual for recommended grease types. Using the right grease keeps the drill running quiet and smooth.

Where To Buy Quality Grease

Quality grease is available at hardware stores and online shops. Buy from trusted brands for best results. Some stores specialize in power tool accessories. These places often have grease made for rotary hammer drills. Check product labels to confirm compatibility. Avoid cheap grease that may harm your tool. Read reviews and ratings to find reliable products. Having the right grease on hand helps you maintain your drill properly.

Tools And Materials Needed

Preparing to grease a Milwaukee rotary hammer drill requires specific tools and materials. These ensure the job goes smoothly and the drill works well after maintenance.

Gathering everything before starting saves time. It also helps avoid mistakes and keeps you safe during the process.

Essential Tools

You will need a clean cloth to wipe dirt and old grease. A small brush helps remove debris from tight spaces. Use a grease gun or applicator for precise grease application. Have the correct type of grease made for rotary hammer drills. A screwdriver or hex key may be needed to open the drill casing. Keep a container nearby to hold screws and small parts safely.

Safety Gear

Wear safety glasses to protect your eyes from dust and grease splashes. Use gloves to keep your hands clean and avoid skin irritation. A dust mask can protect your lungs if dust is present. Work in a well-ventilated area to avoid inhaling fumes. These precautions make the task safer and more comfortable.

Preparing The Drill For Greasing

Preparing your Milwaukee rotary hammer drill for greasing is an important step. It helps keep the tool working smoothly and lasts longer. Before you start greasing, you need to get the drill ready. This ensures safety and makes the process easier.

Cleaning the drill and taking off certain parts helps you reach the areas that need grease. It also stops dirt from mixing with the grease. Follow these simple steps to prepare your drill properly.

Power Off And Unplug

First, always turn off the drill. Make sure the switch is in the off position. Then, unplug the drill from the power source. This stops any chance of it turning on while you work. Safety is the top priority.

Check the power cord for any damage. If the cord is worn out, do not use the drill until it is fixed. Handling power tools without unplugging can cause serious injury.

Removing The Chuck And Accessories

Next, remove the chuck and any attached accessories. Use the right tool to loosen the chuck if it is tight. Take off drill bits, chisel heads, or other parts carefully.

Removing these parts gives you better access to the drill’s inner mechanisms. It also helps prevent grease from getting on the accessories. Keep all parts in a safe place to avoid losing them.

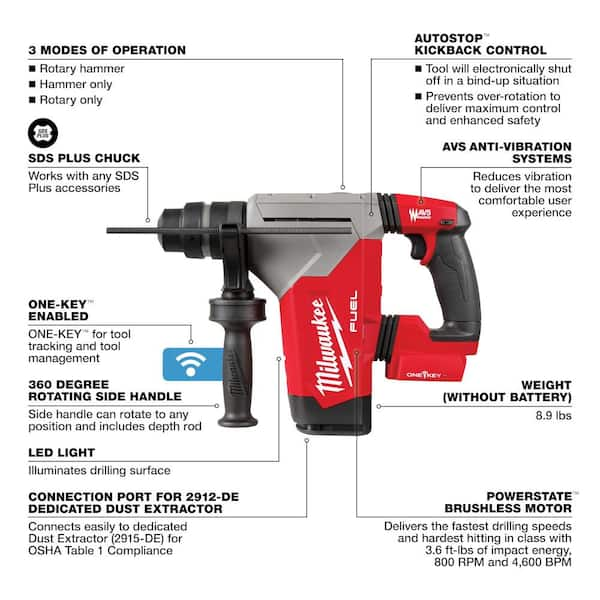

Credit: www.homedepot.com

Disassembling The Rotary Hammer Drill

Disassembling the Milwaukee rotary hammer drill is the first step in proper maintenance. Careful disassembly helps you reach the parts that need greasing. Follow each step to avoid damage and ensure smooth reassembly. Understanding the internal layout makes this process easier.

Accessing The Gearbox

Start by unplugging the drill or removing the battery. Remove all screws on the drill’s outer casing. Use a screwdriver that fits well to avoid stripping the screws. Gently separate the two halves of the casing. Inside, locate the gearbox, usually near the motor. Take note of any washers or small parts you find. Keep these parts organized for reassembly. Avoid forcing the casing apart to prevent breaking clips.

Handling Internal Components

Once the gearbox is visible, handle all parts with care. Use a clean cloth to wipe away dust and old grease. Identify the gears, bearings, and shafts that need lubrication. Avoid touching delicate springs or electrical parts directly. Place small parts in a container to avoid loss. Inspect each component for wear or damage. Clean parts thoroughly before applying new grease. This careful handling ensures your drill runs smoothly.

Cleaning Old Grease And Debris

Cleaning old grease and debris is key to keeping your Milwaukee rotary hammer drill working well. Dirt and thick grease can slow down the tool and cause damage. Removing these buildups helps the new grease work better and lasts longer. Take your time to clean every part carefully for best results.

Using Cleaning Agents

Choose a mild cleaning agent like rubbing alcohol or a dedicated tool cleaner. Avoid harsh chemicals that can harm the tool’s parts. Apply the cleaner to a cloth or brush, not directly on the drill. Gently scrub the old grease and dirt. Repeat until the surface looks clear and free of grime.

Wiping And Drying

Use a clean, dry cloth to wipe off all moisture and loosened debris. Make sure no cleaner remains on the parts. Let the tool air dry for a few minutes before applying new grease. Dry parts prevent rust and help the grease stick better to moving parts.

Credit: www.reddit.com

Applying New Grease Correctly

Applying new grease correctly is essential for the smooth operation of your Milwaukee rotary hammer drill. Proper greasing reduces friction and wear, keeping the tool in good condition. It also helps prevent overheating and extends the drill’s life. Follow the right steps to apply grease carefully and efficiently.

Amount To Use

Use the correct amount of grease to avoid problems. Too little grease will not protect the parts well. Too much grease can cause the drill to clog or leak. Apply a thin, even layer of grease on moving parts. A pea-sized amount usually works for most areas. Spread it gently with your finger or a small tool. Check the user manual for exact grease quantity recommendations.

Areas To Focus On

Focus on key areas that need lubrication. The gear housing is one of the most important spots. Apply grease around the gears carefully. The chuck where the drill bit fits also needs grease. This keeps the bit turning smoothly without slipping. Don’t forget the bearings and any sliding parts. Clean old grease away before adding new grease. This prevents dirt buildup and ensures better performance.

Reassembling The Drill

Reassembling the Milwaukee rotary hammer drill is a crucial step after greasing. It ensures the tool works smoothly and lasts longer. Careful reassembly helps avoid damage and keeps performance at its best.

Putting Components Back

Start by placing all parts in the order you removed them. Insert the gears carefully to avoid misalignment. Fit the motor and gearbox back into the housing gently. Use a clean cloth to wipe any excess grease from surfaces. Tighten screws evenly to hold parts firmly without cracking the plastic.

Ensuring Proper Fit

Check each component’s position before tightening screws fully. The parts should move smoothly with no tight spots. Listen for unusual sounds when turning the drill by hand. Make sure the chuck and handle fit snugly. Proper fit prevents wear and keeps the drill running well.

Testing The Drill After Greasing

Testing the Milwaukee rotary hammer drill after greasing is a key step. It confirms the grease spreads properly inside. This step also checks the drill runs smoothly without issues. Testing helps catch problems early, saving time and cost on repairs.

Running The Drill Safely

Before starting, wear safety glasses and gloves. Hold the drill firmly with both hands. Keep the drill away from your body and others. Turn on the drill at low speed first. Watch for any unusual movement or noise. Stop immediately if you see sparks or smoke.

Listening For Smooth Operation

Listen closely to the drill’s sound as it runs. A well-greased drill sounds smooth and steady. Grinding or rattling noises mean grease may not be spread well. If you hear harsh sounds, stop and check the grease again. The drill should run quietly without jerking or stalling.

Maintenance Tips For Longevity

Proper maintenance extends the life of your Milwaukee rotary hammer drill. Greasing is a key part of this care. It keeps the internal parts moving smoothly. Without regular greasing, the drill may wear out faster. Follow simple tips to keep your tool in top shape.

Regular Greasing Schedule

Set a routine to grease the drill often. Check the user manual for the recommended frequency. Usually, greasing after every 20 hours of use works well. Clean the drill parts before applying fresh grease. Use only the grease type suggested by Milwaukee. This prevents damage and ensures proper lubrication. Avoid over-greasing as it can cause dirt build-up.

Storage Recommendations

Store the drill in a clean, dry place. Keep it away from moisture to stop rust. Use a case or toolbox for protection. Remove excess grease before storing. This prevents dust and grime from sticking. Let the drill cool before putting it away. Proper storage helps maintain grease quality and tool condition.

Credit: www.youtube.com

Frequently Asked Questions

How Often Should I Grease A Milwaukee Rotary Hammer Drill?

You should grease your rotary hammer drill every 3 to 6 months. Regular greasing ensures smooth operation and prevents wear. Check the user manual for specific intervals. Proper maintenance extends the drill’s lifespan and maintains performance.

What Type Of Grease Is Best For Milwaukee Rotary Hammer Drills?

Use high-quality lithium-based grease for Milwaukee rotary hammer drills. This type withstands high pressure and temperature. It ensures proper lubrication and protects internal components. Avoid using general-purpose or automotive grease to prevent damage.

Can I Grease The Drill Without Disassembling It?

No, you need to partially disassemble the drill to access grease points. Proper cleaning and application require opening the housing. This ensures grease reaches moving parts effectively. Follow the manufacturer’s instructions for safe disassembly.

What Are Signs My Rotary Hammer Drill Needs Greasing?

Signs include unusual noise, overheating, and reduced performance. If the drill feels stiff or struggles during use, it likely needs grease. Regular checks help detect lubrication issues early and avoid costly repairs.

Conclusion

Greasing your Milwaukee rotary hammer drill keeps it working well. Clean the drill parts before applying fresh grease. Use the right type of grease for best results. Regular maintenance helps prevent damage and extends tool life. Take your time and follow the steps carefully.

A well-greased drill runs smoothly and lasts longer. Keep your tool ready for any tough job ahead. Simple care makes a big difference in performance.