Are you struggling to figure out how to reverse your Craftsman drill driver? Whether you’re stuck on a tricky project or just want to tighten screws the right way, knowing how to switch your drill’s direction can save you time and frustration.

In this guide, you’ll learn simple steps to quickly reverse your Craftsman drill driver, so you can work smarter and finish your tasks with ease. Keep reading to unlock the secret to mastering your tool like a pro.

Credit: www.youtube.com

Choosing The Right Craftsman Drill Driver

Choosing the right Craftsman drill driver is key for easy reversing. Not all models have the same features. Picking the correct one saves time and effort. It also prevents damage to the tool or workpiece.

Understanding which model suits your needs helps. Craftsman offers many drill drivers with different functions. Knowing what to check ensures smooth reversing and better control.

Identifying Drill Driver Models

Craftsman drill drivers come in corded and cordless types. Each model has a specific design and power level. Look for the model number on the tool or packaging. It usually starts with letters followed by numbers.

Check the tool’s manual or label for detailed info. This helps find the drill driver’s exact type and features. Some models have built-in reversing switches. Others may require manual adjustments.

Checking Compatibility For Reversing

Not all Craftsman drill drivers reverse the same way. Confirm if the model has a reverse switch near the trigger. This switch allows easy change of drill direction.

Some older or basic models might lack a reverse function. For these, reversing could need extra tools or be impossible. Always verify the drill driver’s specifications for reversing capability.

Compatibility with batteries or chargers also matters. Using the correct battery ensures steady power during reversing tasks. This keeps your work efficient and safe.

Credit: www.ebay.com

Tools Needed For Reversing

Reversing a Craftsman drill driver is a simple task that requires a few basic tools. Having the right tools ready makes the process smooth and safe. Prepare everything before you start to avoid interruptions and mistakes.

Basic Hand Tools

You need a small screwdriver to open the drill casing. A Phillips head screwdriver works best for most models. A pair of pliers helps to hold small parts firmly. A small wrench may be useful for loosening tight screws or bolts. Keep a clean cloth nearby to wipe off dust or grease from parts.

Safety Equipment

Wear safety glasses to protect your eyes from dust and debris. Use gloves to keep your hands safe and clean. Work in a well-lit area to see parts clearly. Avoid loose clothing or jewelry that may catch on the drill parts. These safety steps help prevent accidents during the reversing process.

Locating The Reverse Switch

Knowing where the reverse switch is on a Craftsman drill driver is important. This small switch controls the drill’s direction. It helps you loosen screws or drill in reverse. Finding it fast saves time and effort during your work.

Common Switch Positions

The reverse switch usually sits near the drill trigger. On most Craftsman models, it is a small lever or button. It slides left or right or moves up and down. One side makes the drill spin forward.

The other side is for reverse. Sometimes the switch has symbols like arrows. An arrow pointing left means reverse. Right means forward. The middle position often stops the drill from moving.

How The Reverse Mechanism Works

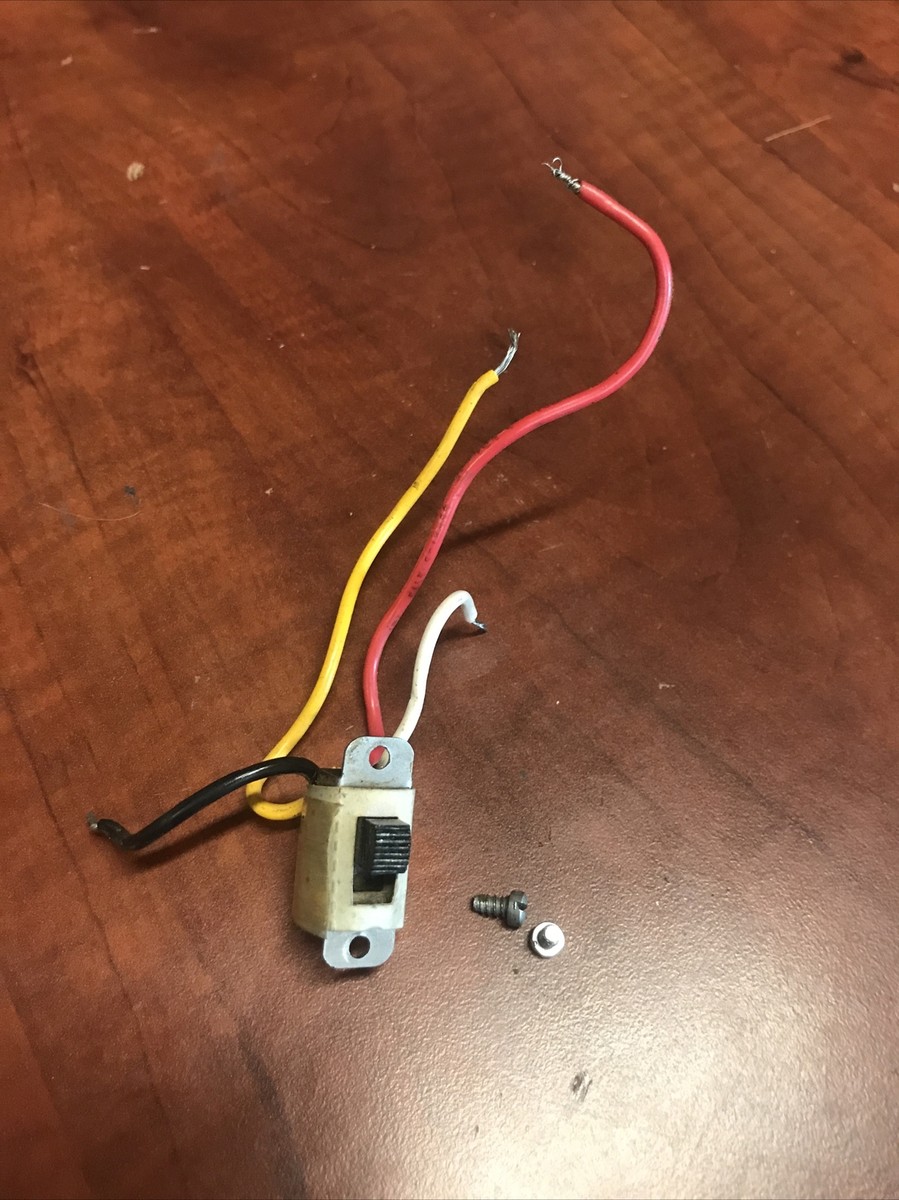

The reverse switch changes the motor’s rotation direction. Inside, it flips the electric current flow. This switch moves a small internal part called a brush or gear. This part changes how power moves through the motor.

When reversed, the drill turns opposite to its normal spin. This helps remove screws or back out drill bits stuck in material. Using the reverse switch correctly keeps your work smooth and safe.

Credit: www.etsy.com

Step-by-step Reversing Process

Reversing a Craftsman drill driver is simple with the right steps. This guide walks through the process clearly. Follow each step carefully to avoid damage. Make sure to work safely and patiently. Let’s start with the basics.

Power Off And Unplug

Always turn off the drill first. Remove the power source or battery. This stops any accidental starts. Safety comes before anything else. Check twice to be sure the drill is off.

Accessing The Internal Components

Remove the screws holding the drill casing. Use a screwdriver that fits well. Gently open the casing to avoid damage. Look for the switch and gears inside. Keep screws in a safe place for reassembly.

Adjusting The Switch Or Gear

Find the reverse switch or gear mechanism. Move the switch to the opposite position. If the switch is broken, replace it carefully. Some drills use a small lever or button. Adjust the gear if needed for proper reverse function.

Testing The Reverse Function

Close the drill casing without tightening screws fully. Plug in or reattach the battery. Turn on the drill and test reverse mode. The drill bit should spin backward smoothly. If not, check the switch and gears again.

Troubleshooting Reverse Issues

Troubleshooting reverse issues in your Craftsman drill driver can save time and money. Reverse function problems often stop the drill from working correctly. Understanding common causes helps you fix the issue faster.

Switch Malfunctions

The reverse switch controls the drill’s direction. Dirt or wear can cause it to fail. Test the switch by moving it back and forth. If it feels loose or does not click, it may need cleaning or replacement. Use a multimeter to check for electrical continuity. A bad switch blocks reverse power flow.

Motor Problems

The motor powers the drill’s rotation. Overheating or worn brushes can reduce reverse function. Listen for unusual sounds or weak power. Brushes wear down after long use and cause poor contact. Replace brushes to restore motor strength. If the motor overheats, let it cool before use. Faulty motors may require professional repair.

Gearbox Failures

The gearbox transmits power to the drill bit. Damaged gears can stop reverse movement. Grinding noises or slipping gears suggest trouble. Check for broken or worn gears inside the gearbox. Gear oil can dry up, causing stiffness. Clean and lubricate gears for smoother operation. Replace damaged gears for full reverse power.

Maintenance Tips For Longevity

Proper care extends the life of your Craftsman drill driver. Simple maintenance keeps it working well and avoids costly repairs. Follow these easy tips to protect your tool and ensure long-lasting performance.

Regular Cleaning

Keep the drill driver clean after each use. Wipe off dust and dirt with a dry cloth. Use a small brush to clear debris from vents and moving parts. Avoid water or harsh chemicals that can damage the tool. Clean tools work smoothly and last longer.

Lubrication Practices

Apply a small amount of oil to the drill’s moving parts regularly. This reduces friction and prevents wear. Use light machine oil for best results. Avoid over-oiling; too much can attract dirt. Proper lubrication keeps the drill running quietly and efficiently.

Storage Recommendations

Store the drill driver in a dry, cool place away from moisture. Use the original case or a toolbox to protect it from dust and damage. Avoid places with extreme temperatures. Proper storage prevents rust and keeps the battery healthy.

When To Seek Professional Help

Sometimes, fixing a Craftsman drill driver on your own can be tricky. Some problems need expert skills and tools. Knowing when to seek professional help saves time and keeps you safe. It also prevents more damage to your tool.

Signs Of Complex Damage

Look for strange noises or burning smells from the drill. If the drill stops working suddenly or the reverse function fails repeatedly, these are warning signs. Loose or broken parts inside the drill need careful inspection. Also, if the drill overheats quickly or the battery drains fast, it shows internal issues. These problems often require a trained technician.

Authorized Service Centers

Authorized service centers use genuine parts and follow the manufacturer’s rules. They have the right tools to fix your Craftsman drill driver. Repairs done here maintain your tool’s warranty. These centers also offer professional advice on maintenance. Visit an authorized center if you notice serious issues or after a major repair.

Frequently Asked Questions

How Do I Reverse A Craftsman Drill Driver?

To reverse a Craftsman drill driver, locate the forward/reverse switch near the trigger. Slide it to the reverse position. This changes the drill’s rotation direction for removing screws or backing out drill bits.

What Is The Forward/reverse Switch On Craftsman Drills?

The forward/reverse switch controls drill rotation direction. Forward drives screws in, reverse backs them out. It is usually a small lever near the trigger for easy thumb access.

Can I Change Drill Direction While Operating?

Yes, you can switch direction while operating, but release the trigger first. This prevents damage and ensures smooth transition from forward to reverse or vice versa.

Why Use Reverse Mode On A Drill Driver?

Reverse mode removes screws, loosens stuck bits, and clears drill holes. It prevents damage by safely backing out fasteners or bits without forcing them.

Conclusion

Reversing a Craftsman drill driver is simple and quick. Just locate the direction switch near the trigger. Push it to the opposite side to change rotation. This helps when you need to remove screws or back out drill bits. Practice this a few times to get comfortable.

Always make sure the drill is off before switching. Now, you can handle your drill more confidently. Keep this tip in mind for your next project. It saves time and makes work easier.