Are you thinking about building your own 80 percent lower but aren’t sure if you need a drill press? You might be wondering if a regular drill will do the job or if investing in a drill press is really worth it.

The truth is, the tools you choose can make a big difference in how easy and precise your project turns out. You’ll discover what a drill press can do for you, when it’s necessary, and how it could save you time and frustration.

Keep reading to find out if a drill press is the right choice for your build and how to get the best results.

What Is An 80 Percent Lower

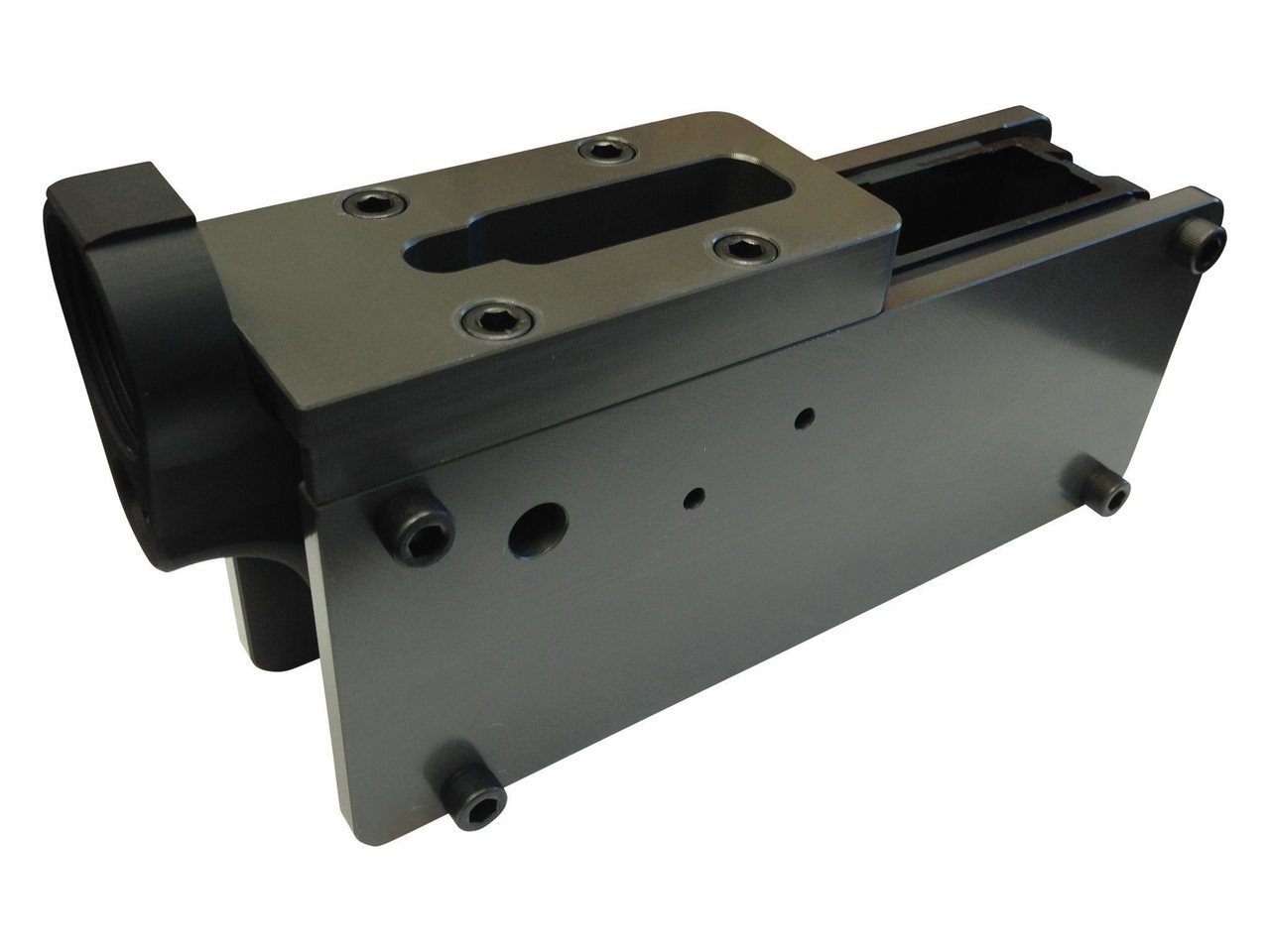

An 80 percent lower is a partially finished firearm frame. It requires additional work before it becomes a complete lower receiver. This item is popular among hobbyists who enjoy assembling firearms. It offers a chance to customize and build a gun personally. The unfinished state means it is not yet considered a firearm by law.

The process of finishing an 80 percent lower involves drilling and milling. This step turns the raw frame into a functional part of the firearm. Many tools can complete this, but some prefer a drill press for better precision. Understanding what an 80 percent lower is helps with making informed choices about tools and legal matters.

Basics Of An 80 Percent Lower

An 80 percent lower is about 80% complete. It lacks holes and cuts needed for the trigger and other parts. You must finish these areas with tools before use. The part looks like a standard lower receiver but needs work. It is usually made from aluminum or polymer. This unfinished state means it is not yet a regulated firearm. Many people buy it to build custom guns at home.

Legal Considerations

An 80 percent lower is not a firearm legally. It does not require a serial number or background check. Laws vary between states on owning and finishing these parts. Some states restrict or ban making guns at home. It is crucial to research local laws before buying or building. Selling a finished firearm usually requires proper licensing. Ignoring laws can lead to serious penalties. Always follow legal rules to stay safe and compliant.

Credit: www.80percentarms.com

Tools Needed For Completing An 80 Percent Lower

Completing an 80 percent lower requires the right tools. These tools help shape and finish the lower receiver correctly. Having the proper equipment makes the process safer and more precise. Some tools are essential, while others can make the job easier. Understanding these tools helps you prepare better.

Essential Tools List

- Drill or drill press – for precise holes

- End mill or router bit – to remove material

- Calipers – to measure dimensions accurately

- Clamps – to hold the lower firmly

- Safety glasses – to protect your eyes

- File or deburring tool – to smooth edges

- Marker or scribe – to mark drilling points

Optional Tools

- Drill press stand – for better stability

- Vise – to secure the lower during work

- Digital depth gauge – for precise depth control

- Work gloves – for hand protection

- Light source – to improve visibility

- Sandpaper – for finer finishing

Role Of A Drill Press In Building An 80 Percent Lower

Building an 80 percent lower requires careful drilling of precise holes. A drill press can make this process easier and more accurate. It holds the metal firmly in place while drilling. This reduces mistakes and keeps holes straight. Using a drill press helps create a better fit for the firearm parts. It also speeds up the work by providing consistent pressure and speed.

Many builders prefer a drill press because it improves the quality of the final product. It is especially helpful for those who want clean, professional results. The drill press guides the bit exactly where it needs to go. This control is hard to achieve with a hand drill or other tools.

Precision And Accuracy Benefits

A drill press offers high precision and accuracy. It keeps the drill bit steady during the entire process. This prevents the bit from wandering off the mark. The depth of each hole can be controlled easily. This control is important for the proper function of the lower receiver.

Consistent hole size and placement are critical for assembly. A drill press ensures uniform holes across multiple pieces. This reduces the chance of errors that can cause parts to not fit well. The result is a more reliable and durable firearm lower.

Alternatives To A Drill Press

Not everyone has access to a drill press. Alternatives include hand drills, jig systems, or CNC machines. Hand drills are less accurate but can work with a good jig. Jigs help guide the drill bit to the right spot. CNC machines offer the highest precision but cost more and require skills.

Each alternative has pros and cons. Hand drills are affordable but require steady hands. Jigs improve accuracy but still depend on the drill operator. CNC machines are precise but not common for beginners. Choosing the right tool depends on budget, skill, and project goals.

Pros And Cons Of Using A Drill Press

Using a drill press for an 80 percent lower has clear benefits and some downsides. This tool offers precision and control but takes up space and costs money. Understanding these pros and cons helps decide if a drill press fits your needs.

Advantages

A drill press makes drilling holes very accurate. It keeps the drill bit straight and steady. This reduces mistakes and improves the fit of parts. It is easier to repeat the same hole size and depth. The drill press also saves effort because it holds the workpiece firmly. Safety is better as hands stay away from the drill bit.

Disadvantages

A drill press can be expensive for some budgets. It takes up more room than a hand drill. Moving it around is not easy because it is heavy. Setting up the drill press takes extra time. Learning to use it well may require practice. For small jobs, a drill press might feel like too much work.

Step-by-step Guide Without A Drill Press

Working on an 80 percent lower without a drill press is possible. It takes patience and careful steps. This guide will show easy ways to finish your project safely and accurately. Follow these methods to get the job done right.

Using A Hand Drill

Start by securing the lower in a sturdy vise. Use clamps to hold it steady. Mark all drilling points clearly with a fine-tip marker. Select a drill bit that fits the hole size needed. Drill slowly and keep the drill straight to avoid mistakes. Pause often to check depth and alignment. Use cutting oil to keep the drill bit cool. Clean out metal shavings regularly to prevent jamming. Take your time to ensure clean, precise holes. Double-check measurements before starting any hole.

Using A Milling Machine

Mount the lower firmly on the milling machine table. Use a proper jig for better accuracy. Set the milling bit size according to your needs. Align the lower carefully with machine guides. Lower the bit slowly to begin cutting. Move the table precisely to follow your marks. Use coolant to reduce heat during milling. Stop often to inspect the cut and prevent errors. Keep all safety gear on while operating the machine. Milling offers more control for cleaner and precise cuts.

Credit: 3dgunbuilder.com

Cost And Space Considerations

Cost and space are important when choosing tools for building an 80 percent lower. These factors affect your budget and workspace setup. Knowing what to expect helps plan better and avoid surprises. A drill press can be a big help but also demands money and room.

Investing In A Drill Press

A drill press costs more than a handheld drill. Prices vary from budget models to professional-grade machines. Buying a good drill press ensures accurate, clean cuts on your 80 percent lower. It lasts longer and works better than cheap options. This tool is a one-time investment that improves your project quality.

Space Requirements

A drill press needs a stable, flat surface. It takes up more space than handheld tools. You need enough room to move around safely. Also, consider storage space for the drill press when not in use. A dedicated workbench or shop corner is ideal. Small spaces may feel crowded with a drill press installed.

Safety Tips When Working On An 80 Percent Lower

Working on an 80 percent lower requires careful attention to safety. Drilling or milling parts can be risky without the right precautions. Protecting yourself and handling tools properly lowers the chance of injury.

Protective Gear

Always wear safety glasses to protect your eyes from flying debris. Use hearing protection to guard your ears from loud noises. Gloves help protect your hands but avoid loose gloves that can catch in moving parts. Wear a dust mask to avoid breathing in metal dust. Dress in close-fitting clothes to prevent accidents.

Safe Tool Handling

Keep your workspace clean and organized to avoid slips and trips. Check tools before use to ensure they work properly. Hold tools firmly and use both hands when possible. Never force a tool; let it work at its own speed. Turn off and unplug machines before making adjustments. Stay focused and avoid distractions while working.

Credit: www.recoilweb.com

Final Recommendations For Builders

Final recommendations help builders decide the best tools for their projects. Choosing the right equipment affects the quality and ease of building an 80 percent lower. Consider your budget, skill level, and workspace before investing in tools.

Assess Your Skill Level

Beginners may find a drill press hard to use at first. Handheld tools can work but require steady hands. Practice on scrap material before working on your actual lower. Skilled builders gain more from precise tools like a drill press.

Consider Your Workspace

A drill press takes up space. Small work areas might not have room for bulky machines. A compact drill press model can save space. Ensure your workspace is safe and well-lit for better results.

Budget And Tool Investment

Drill presses cost more than handheld drills. Weigh the cost against the benefits of accuracy and ease. Quality tools last longer and improve your building experience. Start small and upgrade tools as your skills grow.

Precision And Accuracy Needs

Precision is key when finishing an 80 percent lower. Drill presses provide consistent, straight holes every time. This reduces errors and wasted material. If accuracy is a priority, a drill press is a smart choice.

Alternatives To A Drill Press

Handheld drills with guides can work for some builders. Jigs help keep holes straight and aligned. These options cost less but need more skill. Choose what matches your comfort and project demands.

Frequently Asked Questions

Do I Need A Drill Press For 80 Percent Lower?

A drill press is highly recommended for precision and safety. It ensures accurate drilling, reducing errors common with hand drills. While not mandatory, it simplifies the process and improves the quality of your 80 percent lower build.

Can I Use A Hand Drill Instead Of A Drill Press?

Yes, you can use a hand drill, but it’s less precise. Hand drills increase the risk of misalignment and uneven holes. A drill press provides better control and accuracy, especially important for fitting firearm components correctly.

What Are The Benefits Of Using A Drill Press?

A drill press offers consistent hole depth and alignment. It enhances safety by securing the workpiece firmly. This tool reduces manual effort and errors, ensuring your 80 percent lower parts fit perfectly for reliable firearm assembly.

Is A Drill Press Expensive For Hobbyists?

Drill presses come in various price ranges, from affordable to professional models. Basic models suitable for 80 percent lowers are often budget-friendly. Investing in one can save time and improve build quality, making it worthwhile for hobbyists.

Conclusion

Choosing a drill press for your 80 percent lower depends on your needs. A drill press offers better precision and control. It helps avoid mistakes and saves time. But, a good hand drill can also work well. Consider your budget and skill level before deciding.

Safety matters most when working on your lower. Take your time and follow instructions carefully. This choice affects your build’s quality and success. Think about what fits your project and comfort best.