Have you ever faced the frustration of trying to remove a stripped screw? It’s a common problem that can stop your project in its tracks.

You might feel stuck, unsure of how to get that screw out without causing more damage. But don’t worry—drilling into a stripped screw is a simple skill you can learn. You’ll discover easy, step-by-step methods to drill out stripped screws quickly and safely.

Keep reading, and you’ll be back on track in no time.

Causes Of Stripped Screws

Stripped screws can cause frustration during any project. Understanding why screws strip helps prevent the problem. It also guides you on how to fix stripped screws properly.

Stripping happens when the screwdriver or drill slips inside the screw head. The screw loses its grip, making removal hard. Several factors cause this damage to screws.

Common Reasons Screws Strip

Using the wrong screwdriver size is a top cause. A loose fit makes the tool slip easily. Applying too much force or turning the screw too fast also strips the head. Poor quality screws often have weak heads. Rust or dirt inside the screw head can cause slipping as well.

Types Of Stripped Screw Damage

Screws can have damaged slots, rounded heads, or broken tips. Slot damage means the screwdriver cannot grip inside the screw. Rounded heads lose the edges needed for turning. Broken tips happen when the screw breaks inside the material. Each type requires a different way to remove the screw safely.

:strip_icc()/BHG-home-improvement-advice-expert-advice-how-to-remove-stripped-screw-06_31239-16a9b36dbd3b40788f63ce09dbe4676c.jpg)

Credit: www.bhg.com

Tools Needed For Removal

Removing a stripped screw needs the right tools. Using proper tools makes the process easier and safer. This guide covers tools to help you remove stripped screws quickly.

Essential Hand Tools

Start with basic hand tools. A screwdriver with a firm grip is important. Choose a screwdriver that fits the screw head tightly. Needle-nose pliers can help to twist out screws. Rubber bands placed over the screw head add extra grip. These tools work well for minor stripping.

Power Tools That Help

Power drills save time and effort. Use a drill with a variable speed setting. A drill bit slightly smaller than the screw head works best. Start slowly to avoid damaging the material. An impact driver offers strong torque for stuck screws. These tools work well on tough or deep screws.

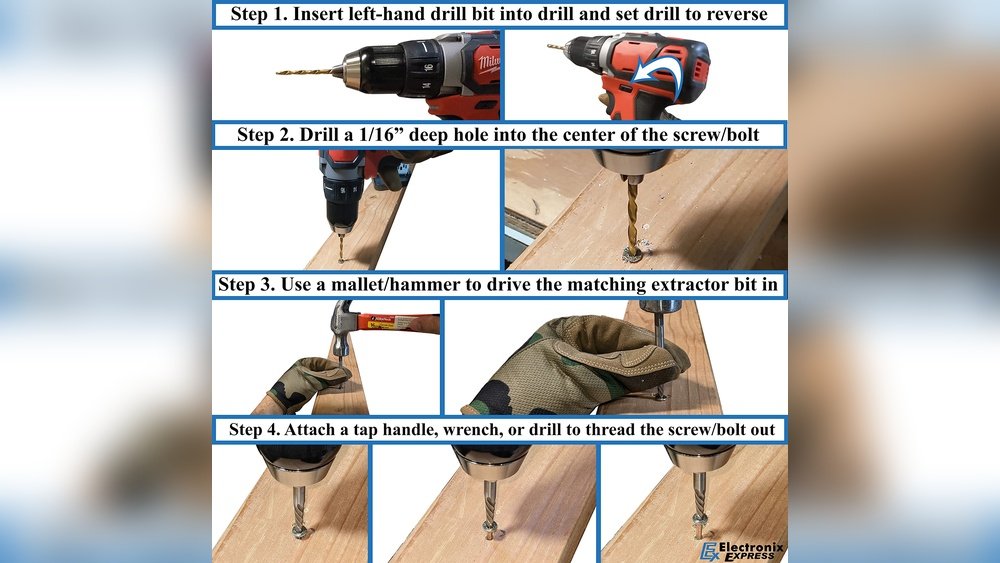

Specialty Screw Extractors

Screw extractors are designed for stripped screws. They have reverse threads to grip the screw tightly. Drill a small hole in the screw first. Insert the extractor and turn it slowly. This tool pulls the screw out without damage. It works best on metal screws and deep stripping.

Prepping The Screw

Prepping the screw is the first step to drilling into a stripped screw. Proper preparation makes the process easier and safer. It helps the drill grip the screw better. This reduces slipping and damage to the surrounding area.

Cleaning And Clearing Debris

Remove dirt and rust from the screw’s surface. Use a small brush or cloth to clean the head. Clear out any debris stuck inside the screw slot. This improves the drill’s contact with the screw. Clean surfaces allow better drilling precision and control.

Applying Lubricants For Easier Removal

Apply a small amount of lubricant on the screw head. Oil or WD-40 works well to loosen rust and grime. Let the lubricant sit for a few minutes. It helps the drill bit turn smoothly. Lubrication reduces friction and makes removal easier.

Credit: www.protoolreviews.com

Drilling Techniques For Stripped Screws

Drilling into a stripped screw requires careful technique to avoid damaging the material around it. Using the right methods helps remove the screw safely and efficiently. Below are key drilling techniques that improve your chances of success.

Choosing The Right Drill Bit

Select a drill bit slightly smaller than the screw head. A metal drill bit works best for most screws. Avoid bits that are too large; they can damage the surface. Start with a bit designed for precision and strength.

Drilling At The Correct Speed

Use a slow to medium drill speed to maintain control. High speed generates heat and can strip the screw further. Apply steady pressure without forcing the drill. This reduces slipping and helps drill cleanly into the screw.

Creating A Pilot Hole

Drill a small pilot hole in the center of the stripped screw head. This gives a better grip for screw extractors or pliers. A pilot hole prevents the drill bit from wandering. It also makes screw removal easier and safer.

Alternative Removal Methods

Stripped screws can be a real headache. Sometimes, drilling is not the best way to remove them. There are simple methods that can help take out these screws without much trouble. These alternative methods save time and reduce damage to your project.

Using Rubber Bands For Grip

Place a rubber band over the stripped screw head. Press the screwdriver firmly into the rubber band. Turn the screwdriver slowly. The rubber band fills in the gaps and gives extra grip. This method works best for slightly stripped screws.

Tapping With A Hammer

Use a hammer to tap the screwdriver gently into the screw head. The tapping helps the screwdriver bite into the screw better. Try turning the screwdriver after tapping. This technique loosens the screw and makes removal easier.

Using Pliers Or Vise-grips

Grab the screw head with pliers or vise-grips. Twist the screw slowly to remove it. This works well if the screw head sticks out. Pliers give a strong grip and avoid slipping. Be careful not to damage the surrounding area.

Credit: accu-components.com

Preventing Future Stripped Screws

Stripped screws cause frustration and slow down projects. Preventing stripped screws saves time and effort. Proper techniques help keep screws strong and secure. Focus on the right tools and methods to avoid damage.

Using Proper Screwdrivers

Select screwdrivers that match the screw head size exactly. A loose fit increases the risk of slipping and stripping. Use screwdrivers with good grip handles for better control. Avoid worn or damaged screwdriver tips.

Applying Correct Pressure And Speed

Apply firm, steady pressure while turning the screw. Pressing too lightly causes slipping. Pressing too hard can damage the screw head. Turn screws at a moderate speed to maintain control.

Choosing The Right Screws For The Job

Pick screws designed for the material you work with. Use screws with appropriate length and thickness. Avoid cheap or low-quality screws that strip easily. Quality screws hold better and last longer.

Frequently Asked Questions

How Can I Drill Into A Stripped Screw Safely?

Use a drill bit slightly smaller than the screw head. Drill slowly to avoid damaging the surface. Apply steady pressure and keep the drill perpendicular to the screw.

What Drill Bit Works Best For Stripped Screws?

A high-speed steel (HSS) bit or cobalt bit works well. Choose a bit smaller than the screw head for better grip. This prevents further damage while drilling.

Can I Remove A Stripped Screw Without Drilling?

Yes, try rubber bands or screw extractors first. Rubber bands increase grip between the screwdriver and screw. Extractors are designed to grip and remove stripped screws easily.

How Do I Prevent Screws From Stripping While Drilling?

Use the correct screwdriver size and type. Apply steady, moderate pressure while turning screws. Avoid over-tightening to reduce the risk of stripping.

Conclusion

Drilling into a stripped screw can seem tough. With the right tools and steps, it becomes easier. Take your time and work carefully. Protect the surrounding area to avoid damage. Practice on old screws to build confidence. This skill helps in many repair tasks.

Stay patient and follow the method closely. Soon, removing stripped screws will feel natural. Keep your tools sharp and ready. You can fix things yourself and save money.