Are you wondering how many belts you really need for your drill press? Choosing the right number of belts can make a big difference in how smoothly your machine runs and how long it lasts.

Too few belts might wear out quickly, while too many could cause unnecessary hassle. You’ll discover the simple truth about drill press belts and learn exactly what works best for your setup. Keep reading to make sure you get the most out of your tool without wasting time or money.

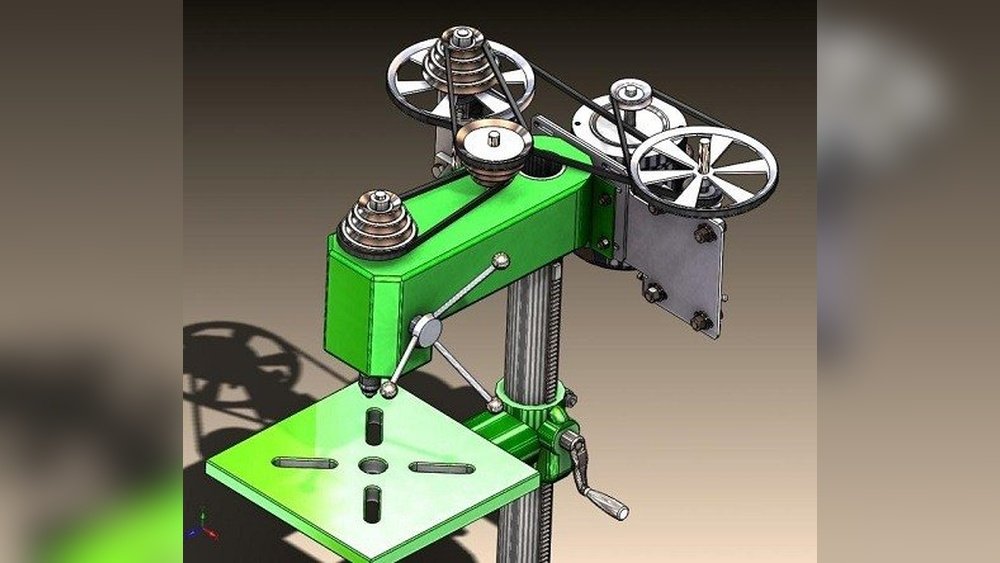

Types Of Drill Press Belts

Drill press belts come in different types. Each belt type has a unique design and use. Knowing these types helps you choose the right belt for your drill press. It also helps maintain the tool’s performance and longevity.

Flat Belts

Flat belts are smooth and wide. They run on flat pulleys and offer quiet operation. These belts are easy to adjust and replace. Flat belts work well with low-speed drill presses.

V-belts

V-belts have a trapezoid shape. They fit into V-shaped grooves on pulleys. These belts provide strong grip and reduce slipping. V-belts are common in medium to high-speed drill presses.

Timing Belts

Timing belts have teeth that fit into matching grooves. This design prevents slipping and keeps the drill press timing exact. Timing belts are used in precision machines needing consistent speed.

Number Of Belts Required

The number of belts required for a drill press depends on the machine’s design and speed control needs. Belts transfer power from the motor to the drill press spindle. The correct number of belts ensures smooth operation and proper speed settings. Choosing the right belt system helps maintain efficiency and extends the drill press life.

Single Belt Systems

Single belt systems use one belt to drive the drill press. This design is simple and easy to maintain. It works well for basic models with fixed speeds. Single belts are quick to replace and cost less. These systems suit hobbyists or those with light drilling tasks.

Multiple Belt Systems

Multiple belt systems use two or more belts to offer variable speeds. Each belt fits a different pulley size for speed adjustment. This setup gives more control over drilling speed. It suits professional or heavy-duty drill presses. Multiple belts can handle tougher materials and longer use. Regular checking and replacing ensure smooth performance.

Factors Affecting Belt Quantity

Knowing how many belts you need for a drill press depends on several factors. These factors affect the number and type of belts required. Understanding them helps you keep your drill press running smoothly. Let’s explore the key factors.

Drill Press Model

Different drill press models use different belt systems. Older models often use flat belts. Newer models may use V-belts or no belts at all. Each model has specific belt sizes and types. Check your drill press manual to know the right belt type. This helps you buy the correct number and style of belts.

Speed Settings

Drill presses offer multiple speed settings. Each speed may require a different belt size or position. Some machines use multiple belts to change speeds easily. More speed settings might mean more belts. This allows the drill press to work well at various speeds. Knowing your speed settings helps plan your belt needs.

Belt Wear And Maintenance

Belts wear out with use over time. Regular maintenance extends their life. Worn or damaged belts need replacement. Having spare belts ready avoids downtime. How often you replace belts depends on use frequency and care. Proper tension and alignment reduce belt wear. Keep belts clean and inspect them regularly.

Credit: www.reddit.com

Choosing The Right Belt

Selecting the right belt for your drill press is important. The belt helps transfer power from the motor to the drill. A good belt keeps the drill running smoothly and safely. Choosing the wrong belt can cause slipping or damage. Focus on material, size, and durability to find the best belt for your drill press.

Material Considerations

Belts come in different materials like rubber, leather, and synthetic compounds. Rubber belts offer good grip and flexibility. Leather belts are strong and last longer but need more care. Synthetic belts resist heat and wear well. Pick a material that suits your drill press use and environment.

Size And Fit

The belt must fit perfectly around the pulleys. Too tight belts cause strain on the motor and parts. Too loose belts slip and reduce power. Measure the belt length and width carefully. Check the drill press manual for the exact belt size. A proper fit ensures efficient and safe operation.

Durability And Performance

Choose belts designed for long life and steady performance. Look for belts that resist stretching and cracking. Durable belts save money by lasting longer. Quality belts maintain consistent speed and reduce noise. Investing in a strong belt improves your drill press work.

Replacing And Maintaining Belts

Replacing and maintaining belts on a drill press is important for safety and performance. Worn belts can slip or break, causing problems during work. Regular checks and timely replacements keep the drill running smoothly. Proper care extends the belt life and saves money over time.

Signs Of Wear

Look for cracks or fraying on the belt surface. A shiny, glazed belt means it is slipping. Noise or unusual vibration can also indicate belt wear. Check the belt tension; a loose belt reduces power transfer. Replace belts showing these signs to avoid damage.

Replacement Frequency

Replace belts every 6 to 12 months with regular use. Heavy or daily use may require more frequent changes. Inspect belts often and replace them if wear appears. Old belts lose flexibility and grip, lowering drill press efficiency. Follow the manufacturer’s guide for specific intervals.

Proper Installation Tips

Turn off and unplug the drill press before replacing belts. Remove the old belt carefully without damaging pulleys. Align the new belt properly on both pulleys. Adjust the belt tension to be firm but not too tight. Test the drill press at low speed to check belt grip.

Credit: canadianwoodworking.com

Common Belt Issues And Fixes

Belt problems are common in drill presses and can affect your work quality. Knowing how to spot and fix these issues saves time and money. This section covers common belt problems and simple fixes to keep your drill press running smoothly.

Slipping Belts

Belts slip when they lose grip on the pulleys. This causes the drill to slow down or stop suddenly. Usually, slipping happens because the belt is worn out or loose. Check the belt for cracks or shiny spots. Replace it if it looks damaged. Tighten loose belts by adjusting the tension to stop slipping.

Noise Problems

Unusual noises from the belt area signal trouble. Squeaking or squealing sounds often mean the belt is too tight or dry. Dry belts need a little belt dressing spray. Avoid oil, as it can damage the belt. If noise continues, inspect the pulleys for dirt or damage. Clean or replace parts as needed to reduce noise.

Tension Adjustments

Proper belt tension is key to good drill press performance. Too tight belts wear out faster and stress the motor. Too loose belts slip and reduce power. Adjust the belt tension by loosening the motor mount bolts. Move the motor to tighten or loosen the belt. Test the belt by pressing it; it should flex slightly but not feel loose.

Credit: www.reddit.com

Frequently Asked Questions

How Many Belts Are Needed For A Drill Press?

Most drill presses require only one belt. This belt transfers power from the motor to the drill spindle. However, some models may need more for variable speed control. Check your drill press manual for exact belt requirements to ensure proper operation and safety.

Why Do Drill Presses Use Belts Instead Of Gears?

Belts offer smoother and quieter operation compared to gears. They allow easy speed adjustments by changing belt positions. Belts also reduce vibration and extend the motor’s lifespan. This makes belts ideal for drill press speed control and efficient power transmission.

Can One Belt Fit All Drill Press Speeds?

No, one belt often fits multiple speeds but may not cover all. Some drill presses use different belt sizes or multiple belts for varied speeds. Using the correct belt size ensures optimal performance and prevents damage to the machine.

How To Choose The Right Belt For A Drill Press?

Choose a belt that matches your drill press model and speed range. Measure existing belt dimensions or consult the manufacturer’s guide. Select a durable, high-quality belt to avoid frequent replacements and maintain consistent drilling performance.

Conclusion

Choosing the right number of belts keeps your drill press running well. One or two belts usually fit most machines. Having a spare belt helps avoid downtime during work. Check your drill press model for exact belt types and sizes.

Regular belt care also extends their life. Simple steps make your drilling tasks easier and safer. Keep belts in good shape to ensure smooth operation. This small detail makes a big difference in your workshop.