Have you ever started drilling a hole only to realize it’s off-center? It’s frustrating, wastes materials, and can ruin your entire project.

But what if you could learn a simple, step-by-step way to drill a perfectly centered hole every time? Whether you’re working on wood, metal, or another material, getting this right will save you time and give your work a professional touch.

Keep reading, and you’ll discover easy tips and tricks that anyone can use to drill a hole exactly where it needs to be. Your next project will thank you!

Credit: woodworking.stackexchange.com

Choosing The Right Drill Bit

Choosing the right drill bit is key to drilling a centered hole accurately. The drill bit must match the material and size needed. Picking the wrong type can cause damage or make the hole uneven. This section explains how to select the best drill bit for your task.

Types Of Drill Bits

Several types of drill bits exist for different uses. Twist bits are common and good for wood, plastic, and metal. Spade bits create larger holes in wood quickly. For masonry, use carbide-tipped bits. Step bits work well for thin materials and can make multiple hole sizes. Knowing the bit type helps you pick the right one.

Material Compatibility

Drill bits come in different materials to match the surface. High-speed steel (HSS) bits are versatile for wood, plastic, and soft metal. Cobalt bits handle harder metals well without dulling fast. Carbide bits are best for very hard surfaces like concrete or tile. Using the correct bit material protects your tools and workpiece.

Size Selection Tips

Choose a drill bit size slightly smaller than the desired hole. This allows for clean, precise holes after finishing. Mark the center point on the material before drilling. Use a drill bit gauge or ruler to check sizes. Avoid bits that are too large or too small for the job.

Credit: www.youtube.com

Preparing The Work Surface

Preparing the work surface is the first step to drill a centered hole accurately. A steady and well-marked surface helps guide the drill bit. It reduces mistakes and improves safety. Follow simple steps to set up your work area right.

Marking The Center Point

Start by finding the exact spot where you want the hole. Use a pencil or marker to make a clear dot. Double-check the measurement to ensure it is in the right place. A precise mark helps you drill straight and centered.

Using Center Punches

Next, use a center punch to make a small dent on the mark. This dent stops the drill bit from slipping. Hold the punch steady and tap it gently with a hammer. The small hole guides the drill for a clean start.

Securing The Material

Clamp the material firmly to your work surface. This prevents movement while drilling. Use a vise or clamps for strong support. A secure piece keeps the hole centered and protects your hands.

Drilling Techniques For Accuracy

Drilling a hole exactly in the center needs careful technique. Small mistakes can cause the drill to slip or the hole to be off. Using the right methods helps improve accuracy and makes drilling easier. Focus on speed, stability, and starting steps for best results.

Setting Drill Speed

Choose the correct drill speed for your material. Hard materials need slower speeds to avoid damage. Softer materials allow faster speeds for cleaner holes. Too fast or too slow can cause the drill bit to wander. Adjust speed before you start drilling.

Maintaining Drill Stability

Keep the drill steady and straight while working. Hold the drill with both hands for better control. Use a clamp or guide to hold the workpiece firm. Avoid pushing too hard; let the drill do the work. A stable drill reduces wobbling and keeps the hole centered.

Starting With A Pilot Hole

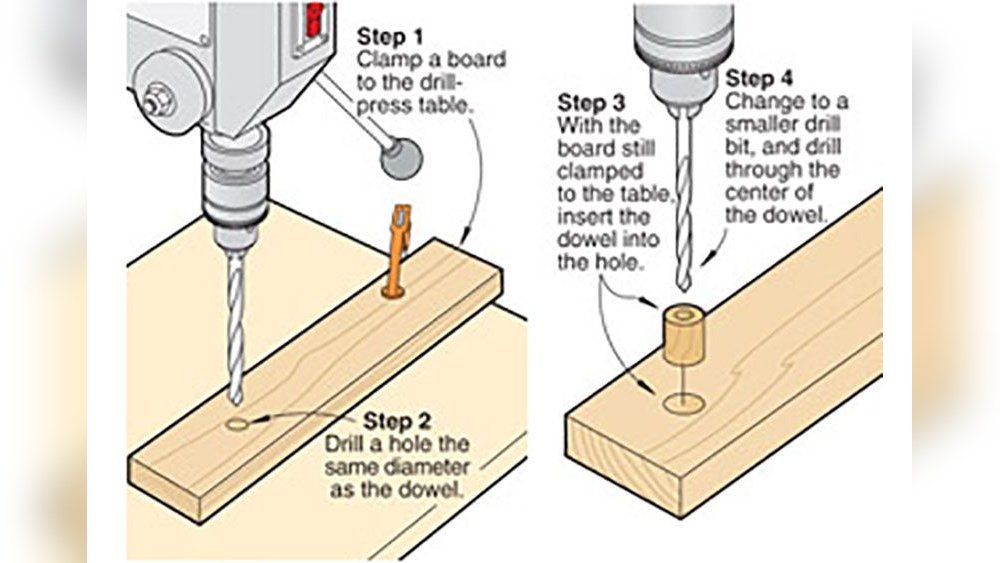

Begin with a small pilot hole to guide the larger drill bit. This hole acts as a path and prevents the bit from slipping. Use a small drill bit first, then switch to the right size. A pilot hole helps make the final hole more precise and clean.

Credit: woodworking.stackexchange.com

Tools And Accessories To Enhance Precision

Drilling a perfectly centered hole requires more than just a steady hand. Using the right tools and accessories can improve your accuracy and make the task easier. These tools help keep the drill steady and guide it exactly where you want.

Drill Guides And Jigs

Drill guides and jigs hold the drill bit in place. They prevent the drill from moving side to side. This keeps the hole straight and centered. Many guides fit different drill sizes. They are simple to use and improve precision a lot.

Clamps And Vises

Clamps and vises hold your workpiece firmly. This stops any movement during drilling. Without movement, the hole stays in the right spot. Clamps come in various shapes for different jobs. Using them makes drilling safer and more accurate.

Laser Alignment Tools

Laser alignment tools shine a light where the drill will go. This helps you see the exact drill spot before starting. The laser line keeps your drill on track. These tools are helpful for precise work on wood or metal.

Common Mistakes To Avoid

Drilling a centered hole may seem simple but many people make mistakes. These errors can ruin your work and waste materials. Avoiding common mistakes improves accuracy and saves time. Focus on key areas to drill perfect holes every time.

Misalignment Issues

Misalignment is a top error when drilling holes. If the drill is not straight, the hole will be off-center. Always check your drill position before starting. Use a guide or clamp to keep the drill steady. Small shifts can lead to large mistakes.

Excessive Pressure

Pressing too hard on the drill causes problems. It can bend the bit or make the hole uneven. Let the drill do the work with gentle, steady pressure. Hard pushing can overheat the bit and damage the material. Slow and steady wins.

Ignoring Drill Bit Wear

Dull drill bits reduce control and accuracy. Worn bits slip and create rough holes. Check your bits often and replace when needed. Sharp bits cut cleaner and help keep holes centered. Regular maintenance saves you from bigger problems later.

Finishing Touches

Finishing touches are key to a clean, accurate hole. They help improve the look and function of your work. Taking time at this stage avoids problems later. Simple steps can make a big difference.

Deburring The Hole

Deburring removes sharp edges around the hole. Use a deburring tool or sandpaper for this task. Run it gently around the hole’s edge. This prevents cuts and helps parts fit better. Smooth edges also improve the hole’s appearance.

Cleaning The Work Area

Clear away dust and metal shavings after drilling. Use a brush or cloth to wipe the surface. A clean area stops dirt from damaging your work. It also keeps tools ready for the next job. Cleanliness helps you see any mistakes easily.

Checking Hole Accuracy

Measure the hole to confirm its size and position. Use a ruler, caliper, or gauge for accuracy. Check if the hole is centered as planned. Small errors can cause problems in assembly. Fix mistakes early to save time and materials.

Frequently Asked Questions

How Do I Mark The Center For Drilling A Hole?

Use a ruler or measuring tape to find the midpoint. Mark it with a pencil. A center punch can create a small dent for accuracy.

What Drill Bit Size Is Best For Centered Holes?

Choose a drill bit matching your hole size requirement. Start with a smaller bit for precision, then enlarge if needed.

How Can I Prevent The Drill From Slipping Off Center?

Use a center punch to make a small guide dent. Drill slowly and hold the drill steady at a right angle.

What Speed Should I Use For Drilling Centered Holes?

Use a slow to medium speed for better control. High speed can cause slipping and reduce accuracy.

Conclusion

Drilling a centered hole takes patience and the right steps. Mark the center clearly before you start. Use a center punch to keep the drill steady. Drill slowly and keep the drill bit straight. Check often to stay on track.

With practice, your holes will look neat and precise. These simple tips help you drill with confidence every time. Keep trying, and your skills will improve quickly.