Are you confused about whether an impact wrench and an impact driver are the same tool? You’re not alone.

Many people mix them up because they sound similar and both help with tightening or loosening bolts and screws. But using the wrong one for your project can slow you down or even damage your work. Keep reading, and you’ll discover the key differences that will help you choose the right tool every time.

This simple knowledge can save you time, effort, and frustration on your next job.

Impact Wrench Basics

The impact wrench is a powerful tool used in many workshops and garages. It helps tighten or loosen bolts fast and with less effort. Understanding the basics of an impact wrench can clear up confusion about its use and function. This section explains what makes an impact wrench unique and useful.

Design And Build

An impact wrench has a strong motor and a hammering mechanism inside. This design gives it extra torque to turn tight bolts easily. It usually has a square drive to fit different socket sizes. The tool feels heavy and solid for better control during use.

Common Uses

People use impact wrenches mostly for car repairs and construction projects. They remove lug nuts on tires and assemble heavy machinery parts. The tool saves time by making tough jobs quicker and easier. It works best on jobs needing high power and torque.

Power Source Options

Impact wrenches come in several power types. Corded electric models need a plug for steady power. Battery-powered versions offer more freedom and mobility. Air-powered impact wrenches connect to an air compressor for strong, continuous force. Each type suits different work environments and needs.

Impact Driver Essentials

Understanding the basics of an impact driver helps in choosing the right tool. This section covers the main features and uses of impact drivers. It also explains the power options available.

Tool Structure

An impact driver has a compact body and a short head. It uses a collet to hold bits, not a chuck. The tool delivers strong twisting force with quick bursts. This design helps in driving screws and bolts fast.

Typical Applications

Impact drivers are great for driving long screws into wood. They work well on tough materials like metal and concrete with the right bit. They are common in construction, woodworking, and automotive tasks. Their power reduces hand strain during repetitive work.

Power Supply Types

Impact drivers come in corded and cordless models. Cordless ones use rechargeable batteries, usually lithium-ion. Battery models offer mobility and ease of use. Corded versions provide continuous power without recharging. Choose based on your work environment and needs.

Torque And Performance

Torque and performance are key factors in choosing between an impact wrench and an impact driver. These tools might look similar but their power and how they work differ. Understanding these differences helps pick the right tool for your job.

Torque Output Comparison

Impact wrenches deliver much higher torque than impact drivers. Torque means the twisting force the tool applies. Wrenches can reach 300 to 1,000 ft-lbs of torque. Impact drivers usually have 1,200 to 2,000 inch-pounds, which is less. This makes wrenches better for heavy-duty jobs like loosening lug nuts.

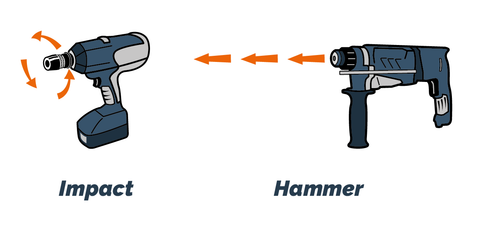

Speed And Impact Mechanism

Impact drivers spin faster than wrenches, often up to 3,000 RPM. They use quick bursts of force to drive screws and small bolts. Impact wrenches work at lower speeds but deliver stronger impacts. Their hammering action breaks loose tight fasteners without stripping them.

Efficiency In Different Tasks

Impact drivers excel in driving screws and light bolts quickly. They are compact and easy to handle. Impact wrenches shine in automotive or construction work. They handle tough nuts and bolts with ease. Choosing the right tool depends on the task’s torque need and speed.

Credit: www.maxtool.com

Size And Portability

Size and portability play a big role in choosing between an impact wrench and an impact driver. These tools look similar but have different shapes and weights. Understanding these differences helps pick the right tool for your job.

Weight Differences

Impact wrenches are usually heavier than impact drivers. This extra weight comes from the larger motor inside. Impact drivers are lighter and easier to carry for a long time. A lighter tool reduces fatigue during long jobs.

Handling And Ergonomics

Impact drivers have a slim design that fits well in your hand. This makes them easier to control in tight spaces. Impact wrenches are bulkier and can feel harder to hold. Ergonomics matter for comfort and precision during work.

Worksite Mobility

Impact drivers are compact and easy to move around with. You can carry them in smaller tool bags or pockets. Impact wrenches need more space and a stronger case for transport. Small size helps speed up tasks on busy worksites.

Bit And Socket Compatibility

Bit and socket compatibility plays a big role in choosing between an impact wrench and an impact driver. Both tools use different attachments to perform tasks. Knowing which bits and sockets fit each tool helps you work faster and smarter. This section explains the types of attachments, their impact on versatility, and how easy it is to change bits.

Types Of Attachments

Impact drivers use screwdriver bits with a 1/4-inch hex shank. These bits fit directly into the driver’s chuck. Impact wrenches work with sockets. They have a square drive, usually 1/2 inch or 3/8 inch. You can attach various socket sizes to match bolts or nuts.

Impact On Versatility

Impact drivers handle screws and small bolts easily. They are great for light to medium tasks. Impact wrenches handle larger nuts and bolts. They are best for heavy-duty jobs like automotive work. The type of attachments affects what each tool can do.

Ease Of Bit Changes

Changing bits in an impact driver is quick. You pull the chuck collar and swap bits fast. Impact wrenches need socket removal and replacement. This takes a bit more time. Using a quick-release socket helps speed up the process.

Applications And Suitability

Impact wrenches and impact drivers serve different purposes. Understanding their applications helps choose the right tool. Each tool fits better in certain tasks. This section explains where each tool works best.

Automotive Repairs

Impact wrenches are common in car shops. They remove and tighten lug nuts fast. Their high torque makes loosening stuck bolts easier. Impact drivers are less common here. They handle smaller screws and bolts well. For heavy car parts, impact wrenches perform better.

Construction Jobs

Construction workers use both tools often. Impact drivers drive screws into wood and metal quickly. They are lighter and easy to control. Impact wrenches handle large bolts in steel structures. They provide more power and speed. Choosing depends on the job size and material.

Diy Projects

DIY enthusiasts prefer impact drivers for home tasks. They fit well for assembling furniture and building decks. Impact drivers are easier to carry and use. Impact wrenches are useful for fixing cars or heavy equipment at home. Both tools add value but suit different tasks.

Cost And Maintenance

Cost and maintenance are key parts of choosing between an impact wrench and an impact driver. Both tools serve different purposes but have unique price points and upkeep needs. Understanding these factors helps you make a smart investment.

Price Range

Impact drivers usually cost less than impact wrenches. You can find impact drivers for around $50 to $150. Impact wrenches often start at $100 and can go over $300. The price depends on power, brand, and features.

More powerful impact wrenches with higher torque tend to be pricier. Impact drivers focus on versatility, so they have a lower cost for casual users.

Durability Factors

Impact wrenches are built for heavy-duty jobs. They handle tough bolts and long hours of work. This means they often have stronger motors and more durable parts. Impact drivers are lighter and designed for everyday tasks.

Durability depends on build quality and usage. Frequent use on hard materials can wear out either tool faster. Proper care can extend their life.

Upkeep Tips

Keep both tools clean and dry to prevent damage. Check the battery health regularly for cordless models. Lubricate moving parts as recommended by the manufacturer. Store them in a cool, dry place away from dust.

Replacing worn-out parts promptly helps avoid bigger repairs. Regular inspection keeps the tools working well and safe to use.

Credit: www.youtube.com

Credit: holemaker-technology.com

Frequently Asked Questions

What Is The Main Difference Between Impact Wrench And Driver?

An impact wrench delivers higher torque for heavy bolts. An impact driver is lighter, designed for screws and small fasteners. Both use impacts, but their power and applications differ significantly.

Can I Use An Impact Driver Instead Of An Impact Wrench?

No, an impact driver is not powerful enough for lug nuts or large bolts. Use an impact wrench for automotive or heavy-duty tasks.

Are Impact Wrenches And Drivers Interchangeable Tools?

No, they are not interchangeable. Impact wrenches fit larger sockets; impact drivers use screwdriver bits. Each tool serves specific purposes.

Which Tool Is Better For Diy Projects, Wrench Or Driver?

Impact drivers are better for DIY due to their compact size and versatility. Impact wrenches suit professional heavy-duty work needing more torque.

Conclusion

Impact wrenches and impact drivers look similar but work differently. Impact wrenches deliver more power for heavy jobs like car repairs. Impact drivers are smaller and better for driving screws and light tasks. Choosing the right tool depends on your needs and the work you do.

Both tools make tasks easier, but knowing their difference helps you pick the best one. Keep this in mind before buying or using either tool. It saves time, effort, and avoids mistakes. Simple and clear.