Have you ever wondered just how deep your drill press can go? Whether you’re working on a simple home project or tackling a complex build, knowing the drilling depth your machine can handle is crucial.

If you push too far, you risk damaging your tool or the material. But if you don’t go deep enough, your project won’t turn out right. You’ll discover exactly how deep a drill press can drill and learn tips to get the most out of your machine every time.

Keep reading to unlock the full potential of your drill press!

Credit: www.woodpeck.com

Drill Press Basics

A drill press is a powerful tool for making precise holes. It holds the drill bit steady and uses a motor to turn it. This setup helps drill deeper and cleaner holes than handheld drills. Understanding the basics of a drill press helps you use it safely and effectively.

Let’s explore the main types, key parts, and common uses of drill presses. This knowledge guides you in choosing the right tool for your projects.

Types Of Drill Presses

There are several types of drill presses. The most common are bench-top and floor models. Bench-top presses sit on a table or workbench. They are smaller and good for light work. Floor drill presses stand on the floor. They are larger and can handle tougher jobs. Other types include radial and magnetic drill presses. Each type suits different tasks and spaces.

Key Components

A drill press has many important parts. The base supports the machine and keeps it steady. The column is a vertical post that holds the table and head. The table holds the workpiece and can move up or down. The head contains the motor and drill chuck. The chuck holds the drill bit firmly. The feed lever lowers the bit into the material. Knowing these parts helps you operate the drill press correctly.

Common Uses

Drill presses are used for many tasks. They drill precise holes in wood, metal, and plastic. They also help with countersinking and reaming. People use drill presses in workshops, factories, and schools. They make repetitive jobs easier and more accurate. The steady speed and depth control improve results and safety.

Factors Affecting Drill Depth

Several factors affect how deep a drill press can drill. Understanding these helps you choose the right setup for your project. Drill depth is not just about power. It also depends on the machine and tools you use. Knowing these limits keeps your work safe and precise.

Spindle Travel Limitations

The spindle moves up and down to drill holes. Its travel distance limits how deep you can drill. Most drill presses have a fixed spindle travel length. This length controls the maximum hole depth. If you need deeper holes, check the spindle travel first.

Drill Bit Length And Type

Drill bits come in many lengths and types. The bit length must be longer than the hole depth. Short bits cannot reach deep holes. Some bits are designed for deep drilling. Use the correct bit to avoid breaking or bending.

Material Thickness And Hardness

Thicker materials require deeper drilling. Hard materials slow down drilling speed. They also cause more wear on the bit. Softer materials are easier to drill through. Consider material type to avoid damage and get clean holes.

Maximizing Drill Depth

Maximizing drill depth is key to getting the best results from your drill press. Drilling deeper holes requires the right tools and settings. With proper steps, you can drill deep without damaging your workpiece or tool.

Selecting The Right Drill Bit

Choose a drill bit designed for deep drilling. Long drill bits are ideal because they reach deeper into the material. Use bits made from strong materials like high-speed steel or carbide. This prevents the bit from breaking during deep drilling. Sharp bits cut cleaner holes and reduce effort.

Adjusting The Drill Press Settings

Set the drill press speed lower for deeper holes. Slower speeds reduce heat and wear on the bit. Adjust the feed pressure to avoid forcing the bit. Too much pressure can cause bending or breaking. Make sure the drill press table is stable and secure to keep the workpiece steady.

Using Extensions And Accessories

Use drill bit extensions to increase drilling depth safely. Extensions attach between the drill chuck and bit. They allow you to reach deeper areas without changing the drill press. Use a coolant or cutting oil to keep the bit cool and reduce friction. This helps maintain bit life during long holes.

Credit: www.woodsmithplans.com

Safety Tips For Deep Drilling

Deep drilling with a drill press requires careful attention to safety. Drilling too deep can cause the bit to bind, break, or damage the workpiece. Taking the right safety steps helps avoid accidents and ensures smooth drilling.

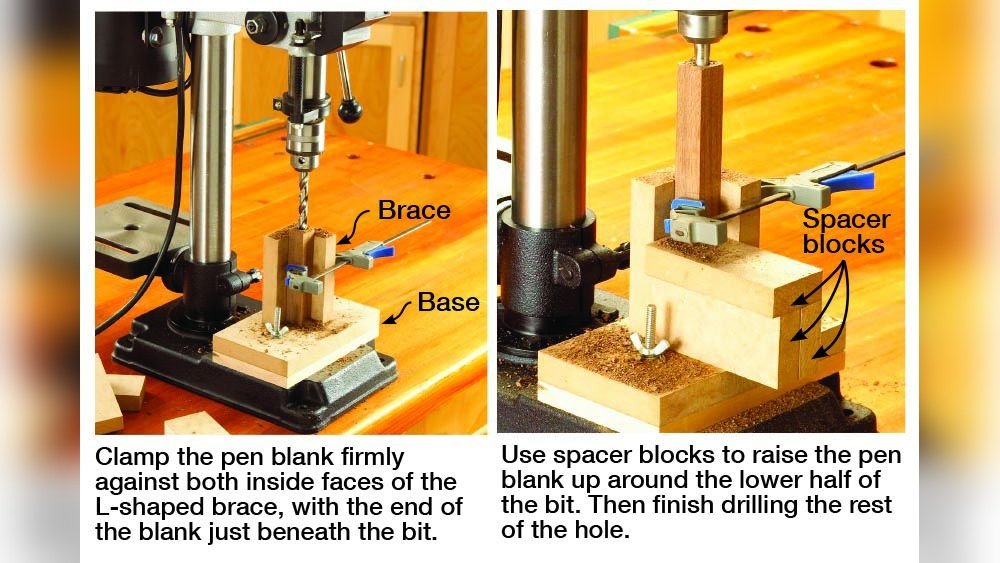

Securing The Workpiece

Always clamp the workpiece firmly before starting. Loose material can spin or shift, causing injury or poor holes. Use a vise or clamps to hold the piece steady. This keeps your hands safe and improves drilling accuracy.

Proper Speed And Feed Rates

Choose the right speed for the drill bit and material. Too fast can overheat the bit. Too slow can cause it to bind. Feed the drill bit gently into the material. Let the drill do the work. Pushing too hard can break the bit or damage the machine.

Avoiding Overheating

Use cutting fluid or oil to cool the bit during deep drilling. Heat wears out bits quickly and can ruin the workpiece. Pause often to let the bit cool down. Overheating increases the risk of bit failure and poor hole quality.

Troubleshooting Common Issues

Drill presses are great tools for precise drilling, but they can face some common problems. These issues can slow down your work or cause damage. Knowing how to fix them can save time and money.

Below are some common problems and easy solutions. This helps you keep drilling smoothly and safely.

Bit Breakage

Bits can break if they are dull or the wrong type. Using too much pressure makes breakage worse. Always use the correct bit for your material. Keep bits sharp for best results. Slow down the speed if the bit overheats. Check for cracks or damage before use.

Inaccurate Depth Control

Depth control issues cause uneven holes. The depth stop may be loose or set wrong. Tighten the depth stop and test on scrap wood. Make sure the table is level and stable. Mark the depth clearly before drilling. Adjust the feed rate for better control.

Drill Press Maintenance

Regular maintenance keeps the drill press working well. Clean the machine after each use to remove dust. Lubricate moving parts to reduce wear. Check belts and pulleys for damage or slack. Tighten all screws and bolts often. Replace worn parts quickly to avoid bigger problems.

Advanced Techniques

Advanced drilling techniques help achieve deeper and more accurate holes. They reduce tool wear and improve safety. These methods are essential for challenging drilling tasks.

Step Drilling

Step drilling uses different drill sizes in stages. Start with a small drill to create a pilot hole. Then, use larger drills to widen the hole gradually. This reduces pressure on the drill bit. It also helps keep the hole straight and clean.

Peck Drilling

Peck drilling means drilling in short bursts. Drill a little, then pull the bit out. This clears chips and dust from the hole. It stops the bit from overheating and breaking. Peck drilling is important for very deep holes.

Using Coolants For Deep Holes

Coolants keep the drill bit and material cool. They reduce heat and friction during drilling. This prevents damage to the drill and workpiece. Use water or oil-based coolants for best results. Coolants also help remove chips from the hole.

Credit: pressbooks.bccampus.ca

Frequently Asked Questions

How Deep Can A Standard Drill Press Drill?

A standard drill press can typically drill up to 3 inches deep. Depth depends on the spindle travel and drill bit length. For deeper holes, specialized bits or equipment may be needed.

What Factors Affect A Drill Press’s Drilling Depth?

Drilling depth depends on spindle travel, drill bit length, and material thickness. The drill press’s chuck and table adjustments also play roles in maximum depth.

Can Drill Presses Drill Through Metal And Wood Equally Deep?

Yes, but drilling depth varies by material hardness and bit type. Metal drilling often requires slower speeds and specialized bits for effective depth penetration.

How To Increase Drilling Depth On A Drill Press?

Use longer drill bits and adjust the table height. Ensure your spindle travel supports the increased depth safely and maintain bit sharpness for clean holes.

Conclusion

A drill press can drill holes as deep as the bit allows. The size and type of the bit matter most. Also, the drill press’s throat depth limits reach. For deeper holes, special bits or setups help. Always choose the right bit for your project.

Safety matters—work slow and steady. With the right tools and care, drilling deep is possible. Keep these points in mind to get the best results.