You just got a new drill press, and you want it to last for years. But do you know the simple steps to keep it clean and protected?

Taking care of your drill press isn’t hard, and it can save you time and money down the road. You’ll discover easy ways to maintain your tool so it works smoothly every time you need it. Keep reading to learn how to make your drill press a reliable partner in all your projects.

Credit: www.nytimes.com

Preparing Your Drill Press

Preparing your new drill press properly sets the stage for effective cleaning and protection. This step helps maintain the machine’s performance and extends its life. Taking time to prepare prevents damage and ensures your safety.

Safety Measures Before Cleaning

Unplug the drill press from the power source first. This stops any accidental starts during cleaning. Wear safety gloves to protect your hands from sharp parts. Use safety glasses to shield your eyes from dust and debris. Avoid loose clothing or jewelry that could get caught in moving parts. Work in a well-ventilated area to reduce dust inhalation. Keep children and pets away from the workspace.

Gathering Necessary Tools

Collect all cleaning supplies before starting. Use a soft cloth to wipe dust and dirt. Have a brush with soft bristles for hard-to-reach spots. Use mild soap or machine cleaner safe for metal parts. Keep lubricating oil handy to protect moving parts. Prepare a small container for screws or tiny parts. Use compressed air to blow out dust from tight spaces. Having all tools ready saves time and effort.

Cleaning The Drill Press

Cleaning your drill press keeps it working well and lasts longer. Regular cleaning removes dirt and dust that can cause problems. A clean drill press runs smoothly and safely. Follow these steps to clean important parts of your machine carefully.

Removing Dust And Debris

Start by unplugging the drill press for safety. Use a soft brush or compressed air to remove dust. Pay attention to vents and motor areas. Dust can block airflow and cause overheating. Clean these spots gently to avoid damage. Remove chips and debris from around the base and table too.

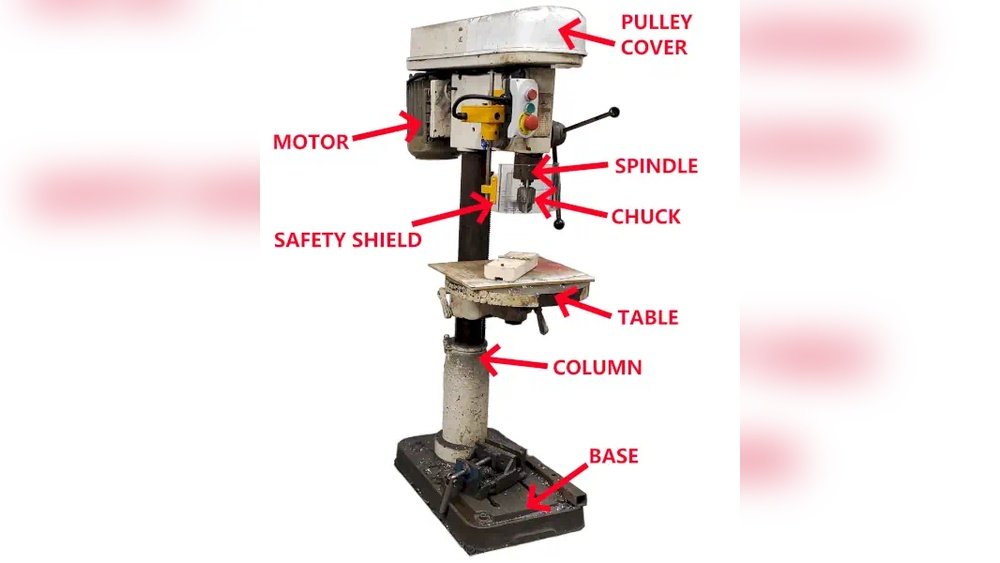

Cleaning The Chuck And Spindle

Open the chuck and wipe inside with a dry cloth. Use a small brush to remove dirt from the teeth. Apply a light machine oil to the spindle to prevent rust. Move the spindle up and down to spread oil evenly. Keep these parts clean to ensure smooth drilling action.

Wiping Down The Table And Base

Use a soft cloth and mild cleaner to wipe the table surface. Remove any grease or stains for better work support. Clean the base carefully to avoid water damage. Dry all parts completely to stop rust. A clean table and base help keep your work steady and safe.

Lubrication And Maintenance

Proper lubrication and maintenance keep a drill press running smoothly. They reduce wear and extend the tool’s life. Regular care prevents rust and damage. This section explains how to lubricate and maintain your new drill press effectively.

Choosing The Right Lubricant

Select oil made for metal tools. Light machine oil works well for most parts. Avoid thick grease unless the manual says so. The right lubricant protects moving parts from friction and rust. Always check your drill press manual for recommended oils.

Applying Oil To Moving Parts

Apply a few drops of oil to gears and spindles. Use a clean cloth to wipe off extra oil. Do this before and after each use. Keep the oil away from belts and electrical parts. Proper oiling ensures smooth movement and less noise.

Checking Belts And Pulleys

Inspect belts for cracks or fraying regularly. Tighten loose belts to avoid slipping. Clean pulleys to remove dust and debris. Replace worn belts promptly to maintain power and accuracy. Good belt and pulley care helps your drill press work at its best.

Credit: www.woodsmithplans.com

Protecting Your Drill Press

Protecting your drill press helps it last longer and work better. Dirt, dust, and moisture can damage parts and cause rust. Taking simple steps can keep your machine safe and in good shape. Regular care saves money on repairs and replacements.

Using Protective Covers

Use a cover made for drill presses. Covers stop dust and dirt from settling on the machine. A good cover also protects from moisture and scratches. Always cover the drill press when not in use. This prevents damage and keeps it clean.

Proper Storage Tips

Store the drill press in a dry, clean place. Avoid damp areas that cause rust. Keep it away from heavy traffic spots to prevent bumps. Place it on a stable surface to avoid tipping. Proper storage keeps the drill press safe and ready to use.

Routine Inspection Schedule

Check your drill press every few weeks. Look for signs of rust, loose parts, or dirt buildup. Tighten screws and bolts if needed. Clean dust from moving parts to keep them smooth. Regular inspections catch problems early and keep your drill press working well.

Troubleshooting Common Issues

New drill presses need care to keep working well. Small problems can stop your work fast. Knowing how to fix these common issues saves time and money. This guide shows easy ways to troubleshoot and protect your drill press.

Addressing Rust And Corrosion

Rust can damage metal parts and slow your drill press. Clean rust spots with a wire brush or sandpaper. Use a rust remover for tough areas. After cleaning, apply machine oil to stop rust from coming back. Keep your drill press in a dry place to avoid moisture buildup.

Fixing Loose Components

Loose parts cause bad drilling and unsafe work. Check bolts, screws, and handles regularly. Tighten any parts that move or wiggle. Use a wrench or screwdriver for a secure fit. Loose belts should be adjusted or replaced to keep the drill running smoothly.

Dealing With Unusual Noises

Strange sounds can mean problems inside the drill press. Listen for grinding, squeaking, or rattling. These noises often come from worn bearings or lack of lubrication. Apply grease to moving parts as needed. Replace damaged parts to avoid bigger issues.

Credit: www.homedepot.com

Frequently Asked Questions

How Often Should I Clean My New Drill Press?

Clean your drill press after every use to prevent dust buildup. Regular cleaning ensures smooth operation and extends the machine’s life.

What Is The Best Way To Lubricate A Drill Press?

Use machine oil on moving parts like the spindle and quill. Proper lubrication reduces friction and prevents rust.

How Do I Protect My Drill Press From Rust?

Apply a thin layer of rust-preventive oil on metal surfaces. Store the drill press in a dry, clean environment to avoid moisture damage.

Can I Use Household Cleaners On My Drill Press?

Avoid harsh household cleaners; use mild soap and water for cleaning. Harsh chemicals can damage metal and painted surfaces.

Conclusion

Cleaning and protecting your new drill press keeps it working well. Regular care stops rust and damage. Use light oil and soft cloths for cleaning. Tighten loose parts to keep it safe. Store the drill press in a dry place.

Small actions prevent big problems later. Enjoy smooth and accurate drilling every time. Your drill press will last longer with simple steps. Stay consistent and check it often. Protect your tool, save money, and work better.