Are you tired of hunting for your cordless drill every time a project calls for it? Imagine having a dedicated drill station where your tool, bits, and chargers are all neatly organized and ready to go.

Building your own cordless drill station is easier than you think, and it can save you time and frustration. You’ll discover simple steps to create a functional, space-saving station that keeps your drill gear within arm’s reach. Ready to transform your workspace and boost your efficiency?

Let’s get started!

Credit: www.woodsmith.com

Choosing The Right Drill Station Design

Building a cordless drill station starts with a smart design choice. The right design keeps your tools safe and easy to reach. It also helps you work faster and stay organized. Think about how you use your drill and what fits your workspace. A good design matches your needs and space.

Consider what type of drill station suits your work style. The design should hold your drill and batteries securely. It should also offer spots for drill bits and small parts. This way, everything stays in one place and you avoid losing items.

Types Of Drill Stations

Drill stations come in many styles. Some are simple stands that hold your drill upright. Others include storage boxes with compartments for bits and chargers. Wall-mounted stations save floor space and keep tools visible. Portable stations let you carry your drill to any job easily.

Choose a type that fits your work habits. If you work in one spot, a wall or bench station works well. For moving around, a portable station makes more sense.

Space Considerations

Measure your workspace before you build. A large station may crowd a small area. Keep enough room to move comfortably. Think about where you will place the station. Near an outlet is best for charging drills and batteries.

Stackable or foldable designs help save space. Also, consider the height of the station. It should be easy to reach without bending or stretching too much.

Material Selection

Choose materials that last and fit your budget. Wood is strong and easy to work with. It can be painted or stained to match your workshop. Plastic is lightweight and resists moisture but may not be as sturdy.

Metal offers durability and a modern look. It handles heavy use well. Combine materials for the best results, like a wooden base with metal hooks. Pick materials that suit your style and the station’s purpose.

Credit: www.woodpeck.com

Essential Tools And Materials

Building a cordless drill station needs the right tools and materials. These items make your work easier and safer. Gather everything before starting. This saves time and helps you work smoothly.

Power Tools Needed

Start with a cordless drill. It is the main tool for this project. A jigsaw helps cut wood precisely. A sander smooths rough edges. A measuring tape ensures accurate cuts. A pencil marks lines for cutting and drilling.

Hardware And Fasteners

Use screws to hold parts together. Choose wood screws for strong joints. Hinges are useful if you want doors or lids. Use drawer slides for smooth drawer movement. Small brackets add extra support where needed.

Safety Gear

Wear safety glasses to protect your eyes. Use ear protection to block loud noises. Gloves keep your hands safe from splinters and cuts. A dust mask prevents inhaling sawdust. Safety gear keeps you safe during work.

Preparing The Workspace

Preparing your workspace is the first step in building a cordless drill station. A clean and organized area helps you work faster and safer. It also makes the project more enjoyable. Set up a place where you can focus on your task without distractions.

Clearing And Organizing

Start by removing all clutter from your workspace. Put away tools and materials you do not need. Group similar items together for easy access. Keep your drill and accessories close. Clear space helps prevent accidents and saves time.

Surface Preparation

Choose a flat and sturdy surface for your drill station. Clean the surface to remove dust and dirt. A smooth surface makes assembly easier. If needed, cover the area with protective material. This protects the surface and keeps parts from slipping.

Lighting And Ventilation

Good lighting is essential for detailed work. Use bright lights to avoid shadows on your workspace. Natural light is best if available. Ensure proper ventilation to keep air fresh. Good airflow helps reduce dust and fumes during work.

Credit: www.woodsmithplans.com

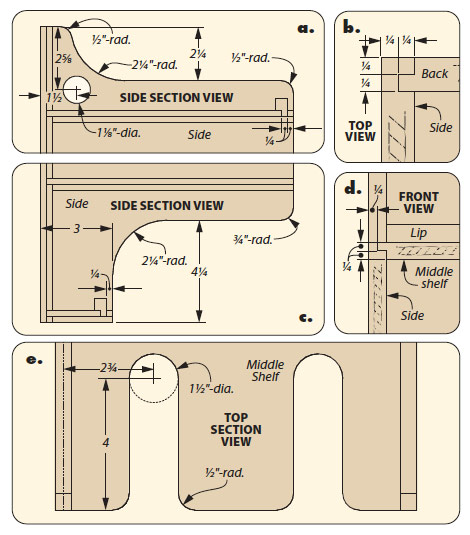

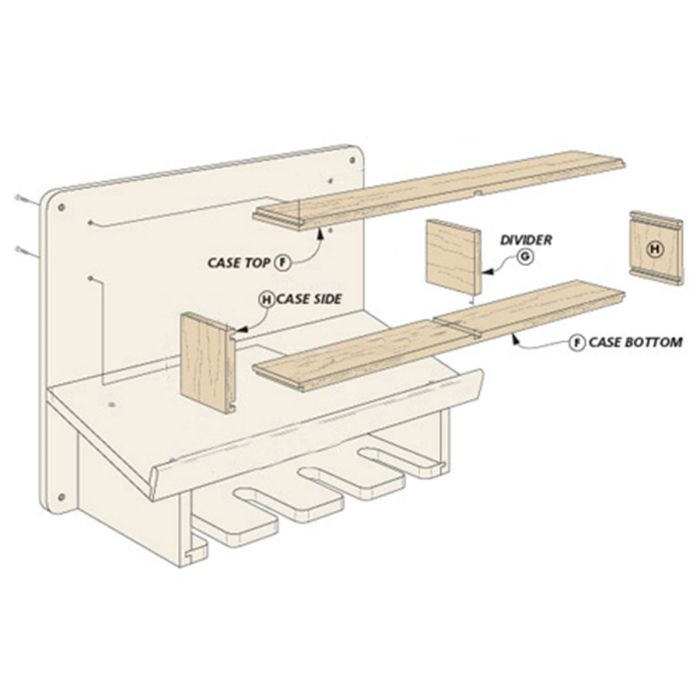

Building The Base And Frame

Building the base and frame is the first step in creating a cordless drill station. A strong base supports the entire structure and keeps it steady. The frame holds the drill and other tools securely. This section shows how to measure, cut, and put together the base and frame for a reliable station.

Measuring And Cutting Wood

Start by choosing wood that is sturdy and easy to work with. Measure the length and width based on the space you have. Use a tape measure for accuracy. Mark the wood with a pencil before cutting. Cut the wood pieces using a saw, following your marks carefully. Keep the edges smooth by sanding them down.

Assembling The Frame

Arrange the cut pieces on a flat surface. Join the wood using screws or nails. Use a drill to make pilot holes to avoid splitting the wood. Attach the sides first, then add supports in the middle for strength. Check that all parts fit tightly without gaps.

Ensuring Stability

Place the base on a level surface. Add rubber feet or pads under the corners to prevent slipping. Tighten all screws and nails securely. Test the frame by applying gentle pressure. It should not wobble or shift. Stability keeps your drill safe and your work steady.

Creating Storage Solutions

Creating storage solutions is key to building a cordless drill station. It keeps tools organized and easy to find. A tidy workspace helps you work faster and safer. Design your storage to fit your tools perfectly. Use space smartly to avoid clutter.

Drill And Battery Holders

Drill and battery holders keep your main tools in place. Use sturdy materials like wood or plastic to build holders. Make slots sized for your drills and batteries. This stops them from falling or getting damaged. Label each holder to know where everything goes.

Accessory Organizers

Accessory organizers store drill bits, screws, and small parts. Use small containers or drawer inserts for easy sorting. Clear containers help you see what’s inside quickly. Group similar items together for faster access. This keeps your station neat and saves time.

Cable Management

Cable management prevents cords from tangling and creating hazards. Use hooks or clips to hold cables neatly on the wall or bench. Velcro straps work well to bundle cables. Keep cables away from moving parts and tools. Organized cables make your drill station safer and cleaner.

Adding Work Surface Features

Adding work surface features makes your cordless drill station practical and efficient. A well-planned surface helps hold materials steady and speeds up your work. Choose features that match your needs and space.

Choosing The Worktop Material

Select a worktop material that is strong and easy to clean. Hardwood like maple or birch lasts long and resists dents. Plywood is cheaper but less durable. Avoid soft materials that wear out fast. A smooth surface makes drilling easier and safer.

Installing Clamps And Vises

Clamps and vises keep your workpieces steady during drilling. Fix a small vise on one corner for tight gripping. Add quick-release clamps for easy adjustments. Position clamps so they do not block your drill or hands. Secure clamps firmly to avoid movement.

Incorporating Measuring Tools

Built-in measuring tools save time and increase accuracy. Attach a ruler or tape measure along the edge of the worktop. Add a square or protractor for angle checks. Keep tools within arm’s reach for fast measuring. Mark common measurements directly on the surface for quick reference.

Finishing Touches

Finishing touches make your cordless drill station both useful and neat. This step ensures everything looks good and works well. Small details improve your experience and safety.

Sanding And Painting

Sanding smooths rough edges and surfaces. Use fine-grit sandpaper for a clean finish. Sanding helps paint stick better and prevents splinters.

Choose paint that resists wear and moisture. Apply thin, even coats for best results. Let each coat dry before adding the next. A painted station looks tidy and lasts longer.

Labeling Storage Areas

Labels help you find tools quickly. Use clear, simple labels for each storage spot. Write the tool name or draw a small picture.

Label battery slots, drill bits, and chargers. This keeps your station organized every day. It saves time and reduces frustration.

Safety Enhancements

Add rubber pads to prevent slipping and damage. Secure cords and chargers to avoid tripping. Check for sharp edges and cover them well.

Install small hooks for safety glasses and gloves. Keep your workspace clean to avoid accidents. Safety makes your drill station a better place to work.

Maintenance Tips For Longevity

Keeping your cordless drill station in good shape extends its life and saves money. Simple care steps help your tools work better longer. A little effort each week prevents bigger problems later. Follow these easy maintenance tips to keep your drill station ready for any job.

Regular Cleaning

Dust and dirt can damage your tools. Clean your drill and station after each use. Use a soft cloth to wipe off debris. Avoid water on electrical parts. Compressed air helps remove dust from hard spots. Clean bits and attachments too. A tidy station works safely and lasts longer.

Inspecting For Wear

Check your drill and parts often. Look for cracks, loose screws, or worn-out bits. Replace damaged parts quickly to avoid accidents. Watch the battery for swelling or leaks. Early fixes keep your tools working well. Inspect cords and chargers for damage as well.

Tool Care Practices

Store your drill in a dry place to stop rust. Keep batteries charged but not overcharged. Use the correct bits for each job to avoid strain. Avoid dropping or banging your tools. Follow the user manual for best care tips. Good habits make your cordless drill station last longer.

Frequently Asked Questions

What Materials Do I Need To Build A Cordless Drill Station?

You need plywood, screws, wood glue, clamps, and paint. Also, gather drill bits, chargers, and storage bins for organization.

How Do I Organize Drill Bits In The Station?

Use labeled compartments or magnetic strips to keep drill bits sorted. This saves time and prevents loss or damage.

Can I Customize The Cordless Drill Station Design?

Yes, customize size and compartments to fit your tools. Tailor it to your workspace and storage needs for efficiency.

How Do I Ensure The Station Is Sturdy And Durable?

Use quality wood, secure joints with screws and glue, and reinforce corners. A solid build supports heavy tools safely.

Conclusion

Building a cordless drill station saves time and keeps tools organized. You can work faster with everything in one place. A simple setup helps you find bits and batteries quickly. Start with basic materials and add what you need. This project fits any workspace and skill level.

Try making your own station today. It makes drilling tasks easier and more fun. Keep your tools ready and your work smooth. A cordless drill station is a smart choice for any DIYer.