Have you ever faced the frustration of a broken bolt stuck deep where you can’t reach it? It can stop your project cold and leave you wondering what to do next.

But don’t worry—drilling out a broken bolt is easier than you think. With the right steps and tools, you can save time, avoid costly repairs, and get your work back on track quickly. In this guide, you’ll discover clear, simple instructions that anyone can follow to remove that stubborn bolt safely and effectively.

Keep reading, and you’ll gain the confidence to tackle this common problem yourself.

Credit: merequipment.com

Tools Needed

Removing a broken bolt needs the right tools. Using proper tools makes the job easier and safer. Below is a list of essential tools for drilling out a broken bolt.

Drill Types

A corded drill gives steady power for tough bolts. Cordless drills offer more freedom and easy handling. Choose a drill with variable speed control. This helps avoid overheating the metal while drilling.

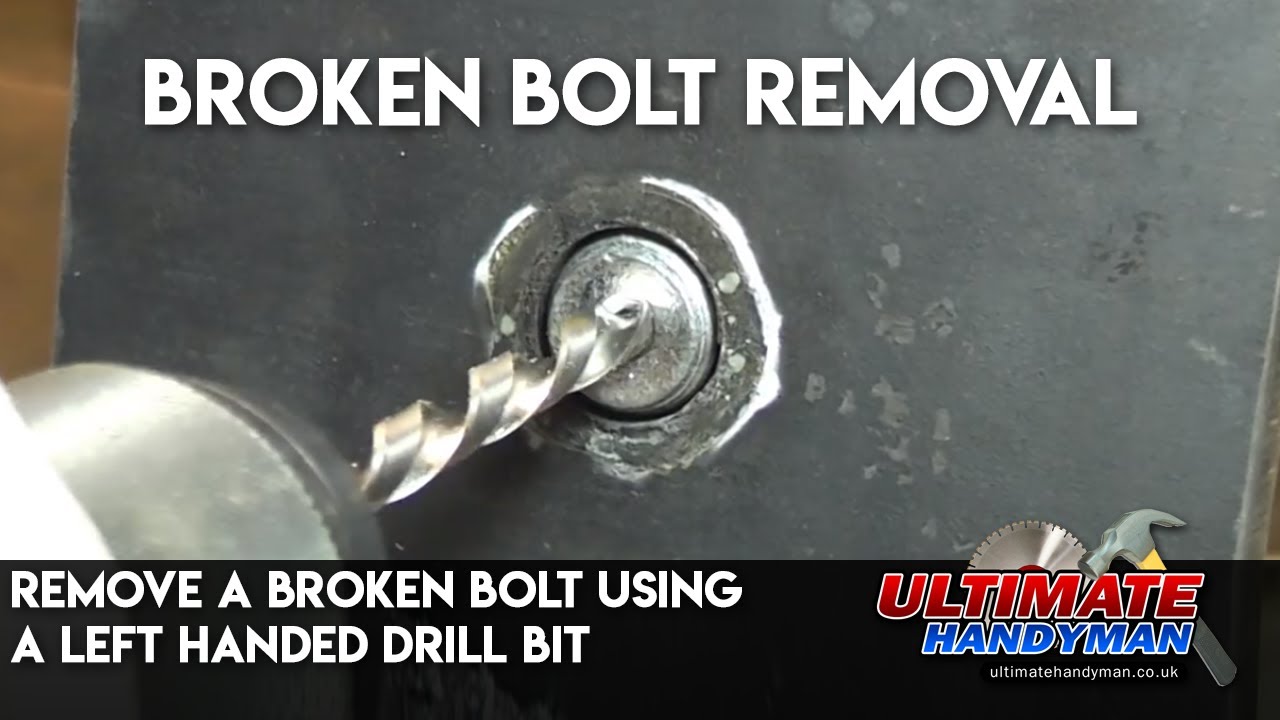

Extractors And Bits

Use bolt extractors designed to grip broken bolts tightly. Left-handed drill bits work well to loosen stuck bolts. Start with a small pilot bit, then increase size carefully. Having the right extractor set saves time and effort.

Safety Gear

Wear safety glasses to protect your eyes from flying metal. Use gloves to keep your hands safe from sharp edges. Hearing protection helps reduce noise from the drill. A dust mask prevents inhaling metal dust during drilling.

Credit: www.aircraft-tool.com

Preparing The Area

Preparing the area before drilling a broken bolt is important for safety and success. A clean and stable workspace helps the drill work better. It also protects the tools and materials from damage. Follow these steps to get ready.

Cleaning The Bolt

Remove dirt and rust from the broken bolt. Use a wire brush or sandpaper to clean the surface. This helps the drill bit grip the bolt better. Clean bolts reduce slipping and make drilling easier. Wipe away any dust or grease with a cloth.

Securing The Workpiece

Keep the workpiece steady before drilling. Use clamps or a vise to hold it firmly in place. A stable workpiece prevents movement that can break the drill bit. It also keeps you safe. Make sure the broken bolt is easy to reach and well-exposed for drilling.

Drilling Techniques

Drilling a broken bolt requires specific techniques to avoid damage and make the job easier. Proper drilling helps remove the bolt safely and quickly. Follow these drilling techniques for better results.

Center Punching

Start by marking the exact center of the broken bolt. Use a center punch to make a small dent on this spot. This dent guides the drill bit and prevents it from slipping. Always use a hammer to tap the center punch gently. A well-marked center point makes drilling precise and easier.

Selecting Drill Speed

Choose the right drill speed based on the bolt material and drill bit size. Slow speeds work best for harder metals and larger bits. Fast speeds may cause overheating and damage the bit. Use steady, moderate speed for small drill bits. Keep the drill bit cool by pausing or using cutting oil.

Drilling Pilot Holes

Begin with a small drill bit to create a pilot hole in the bolt. This hole guides larger drill bits and reduces stress on the bolt. Drill slowly and straight to avoid breaking the bit. Gradually increase the drill bit size until the bolt can be removed. Pilot holes make the process smoother and safer.

Using Bolt Extractors

Using bolt extractors is a common and effective way to remove a broken bolt. These tools are designed to grip the inside of the broken bolt and turn it out. They work well when the bolt is stuck or the head is damaged. The process requires care and the right tools to avoid further damage.

Choosing The Right Extractor

Select an extractor that fits the broken bolt size. Extractors come in different sizes for small and large bolts. Using the wrong size can cause slipping or breakage. Check the bolt diameter before picking an extractor. A snug fit ensures better grip and easier removal.

Inserting The Extractor

First, drill a small pilot hole in the center of the broken bolt. The hole should be straight and deep enough for the extractor to grip. Insert the extractor tip into the hole. Tap it gently with a hammer to secure it inside. This helps the extractor hold the bolt firmly.

Removing The Bolt

Turn the extractor counterclockwise using a wrench or a T-handle. Apply steady, slow pressure to avoid breaking the extractor. The broken bolt will begin to turn and loosen. Keep turning until the bolt is fully removed. If stuck, try applying penetrating oil and wait before trying again.

Alternative Methods

Sometimes, drilling a broken bolt is not the best option. Alternative methods can save time and avoid damage. These methods work well for different situations. They often require simple tools and careful steps. Below are two effective alternatives to drilling.

Heat Application

Applying heat can loosen a stuck bolt. Use a propane torch to heat the bolt area. Heat causes the metal to expand and break the rust bond. Heat the bolt evenly for a few minutes.

After heating, try to turn the bolt gently. Use a wrench or pliers for better grip. Avoid overheating to prevent damage to nearby parts. Heat application is useful for rusty or seized bolts.

Tapping And Thread Repair

Tapping cuts new threads inside the hole after bolt removal. Use a tap tool sized for the bolt. Insert the tap carefully and turn it slowly. This cleans the damaged threads and prepares the hole for a new bolt.

Thread repair kits can help fix damaged threads. They often include inserts that fit into the hole. This restores the thread size and strength. Tapping and thread repair work well after bolt removal or if threads are stripped.

Credit: www.youtube.com

Preventing Future Breakage

Broken bolts often happen because of too much pressure or poor care. Preventing future breakage saves time and money. Simple steps help keep bolts strong and last longer. Follow these tips to avoid the hassle of broken bolts again.

Proper Torque Settings

Using the right torque is key. Tighten bolts just enough, not too much. Over-tightening puts stress on the bolt. This stress can cause cracks or breaks. Use a torque wrench to measure force. Check the bolt’s recommended torque value. Apply steady pressure and stop once reached. Proper torque keeps bolts secure and safe.

Lubrication Tips

Lubrication helps bolts turn smoothly. It lowers friction and reduces wear. Use oil or grease on bolt threads before tightening. Clean the threads first for best results. Avoid too much lubricant; a thin layer is enough. Regular lubrication prevents rust and seizing. This makes bolts easier to remove later. Proper lubrication extends bolt life and strength.

Frequently Asked Questions

How Do I Safely Drill Out A Broken Bolt?

Use a center punch to mark the bolt’s center. Start drilling with a small bit. Increase drill size gradually. Always wear safety goggles and proceed slowly to avoid damaging the surrounding material.

What Tools Are Needed To Drill A Broken Bolt?

You need a drill, center punch, drill bits, penetrating oil, and safety goggles. A bolt extractor set can help remove drilled bolts easily. Proper tools ensure efficient and safe bolt removal.

Can I Reuse The Hole After Drilling A Broken Bolt?

Yes, you can reuse the hole if it’s clean and undamaged. Tap new threads with a suitable tap tool if necessary. Otherwise, use a slightly larger bolt or insert a helicoil for a secure fit.

How Do I Prevent Breaking Bolts In The Future?

Use the correct size and grade bolts. Avoid overtightening by using a torque wrench. Apply anti-seize lubricant before installation to reduce corrosion and seize risks. Proper maintenance extends bolt life.

Conclusion

Drilling a broken bolt takes patience and the right tools. Start with small steps and work carefully. Always use a drill bit that fits the bolt size well. Keep the drill steady and slow to avoid damage. If done right, you can remove the bolt without harming the material.

This skill saves time and money on repairs. Practice makes the process easier. Stay calm and follow the steps for best results.