Have you ever wondered if you can use a milling table with your drill press? If you’re looking to expand your workshop’s capabilities without investing in a full milling machine, this question is probably on your mind.

Using a milling table with a drill press can open up new possibilities for precision and control in your projects. But is it really practical? And what should you watch out for? Keep reading, because we’re about to explore everything you need to know to make the most of your tools and take your DIY skills to the next level.

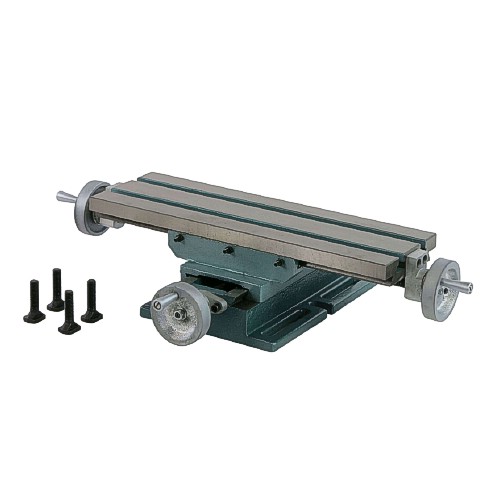

Credit: www.trick-tools.com

Milling Tables And Drill Presses

Milling tables and drill presses are important tools in many workshops. Both help shape and work on metal, wood, and other materials. Using a milling table with a drill press can increase precision and control. Understanding their roles helps you use them better.

Milling tables guide the material during cutting or drilling. Drill presses provide steady, vertical drilling power. Together, they can improve accuracy and make complex tasks easier.

Basic Functions Of A Milling Table

A milling table holds the workpiece firmly in place. It moves the material along set paths. This movement allows precise cuts and drilling. Users can adjust the table forward, backward, left, or right. Some tables also move up and down.

This control helps create exact shapes and sizes. Milling tables reduce mistakes by keeping the work steady. They make detailed work possible on small or large pieces.

Key Features Of A Drill Press

A drill press has a motor that spins a drill bit at high speeds. It uses a vertical spindle to drill straight holes. The press is stable and powerful, better than handheld drills. It allows exact depth and angle control for drilling.

Most drill presses have adjustable speed settings. The height and position of the drill head can change. This flexibility helps work on different materials and sizes. A drill press offers consistent and clean holes every time.

Compatibility Factors

Understanding the compatibility factors is key when using a milling table with a drill press. Not all milling tables fit every drill press. Knowing the size and mounting needs helps avoid problems. Stability also plays a big role. A secure setup ensures better work and safety. Let’s explore these factors closely.

Size And Fit Considerations

The milling table must match the drill press size. Check the table’s dimensions against your drill press table. The width and length should fit without overhanging. The mounting holes on the milling table need to align with the drill press holes. Too big or too small tables cause poor control. Choose a milling table designed for your drill press model.

Mounting And Stability Issues

Mounting the milling table securely is important. Loose mounts cause movement during milling. This affects accuracy and can be unsafe. Use proper bolts and clamps to fix the table firmly. The drill press base should be stable on the floor or workbench. Adding weights or anti-slip pads helps reduce vibrations. A stable setup improves precision and safety in milling tasks.

Benefits Of Using A Milling Table With A Drill Press

Using a milling table with a drill press brings many benefits. It changes how you work and what you can do. This setup helps improve the quality of your projects. It also lets you handle tasks that a drill press alone cannot manage. The extra control and options make it a useful addition for many users.

Enhanced Precision And Control

A milling table adds precise movement to your drill press. You can move your workpiece smoothly in small steps. This control helps you drill exact holes and shapes. It reduces mistakes and improves the finished product. The table often has dials or handles for fine adjustments. This makes your work more accurate and professional.

Expanded Machining Capabilities

With a milling table, your drill press can do more jobs. It allows cutting, shaping, and engraving, not just drilling. You can work on different materials with better results. The table supports complex tasks like making slots or grooves. This expands what you can create in your workshop. It makes your drill press a more useful tool overall.

Credit: www.instructables.com

Limitations And Challenges

Using a milling table with a drill press can seem like a good idea. It allows for more precise control over your workpiece. Yet, there are clear limits and challenges to this setup. Understanding these can help you decide if it fits your needs.

Power And Speed Constraints

Drill presses have less power than milling machines. They often run at lower speeds too. This limits the types of materials you can work on. Hard metals may be too tough for a drill press to mill properly. The motor might overheat or stall under heavy loads. Speed control is also less precise than on a milling machine. This affects the quality of cuts and tool life.

Accuracy And Rigidity Concerns

Drill presses are not built for heavy milling tasks. Their frames and tables are less rigid. This can cause vibration during cutting. Vibration reduces accuracy and surface finish quality. The milling table adds some control but cannot fix all movement. The spindle may have some play, causing tool wobble. This makes fine, detailed milling difficult or impossible.

Setup And Installation Tips

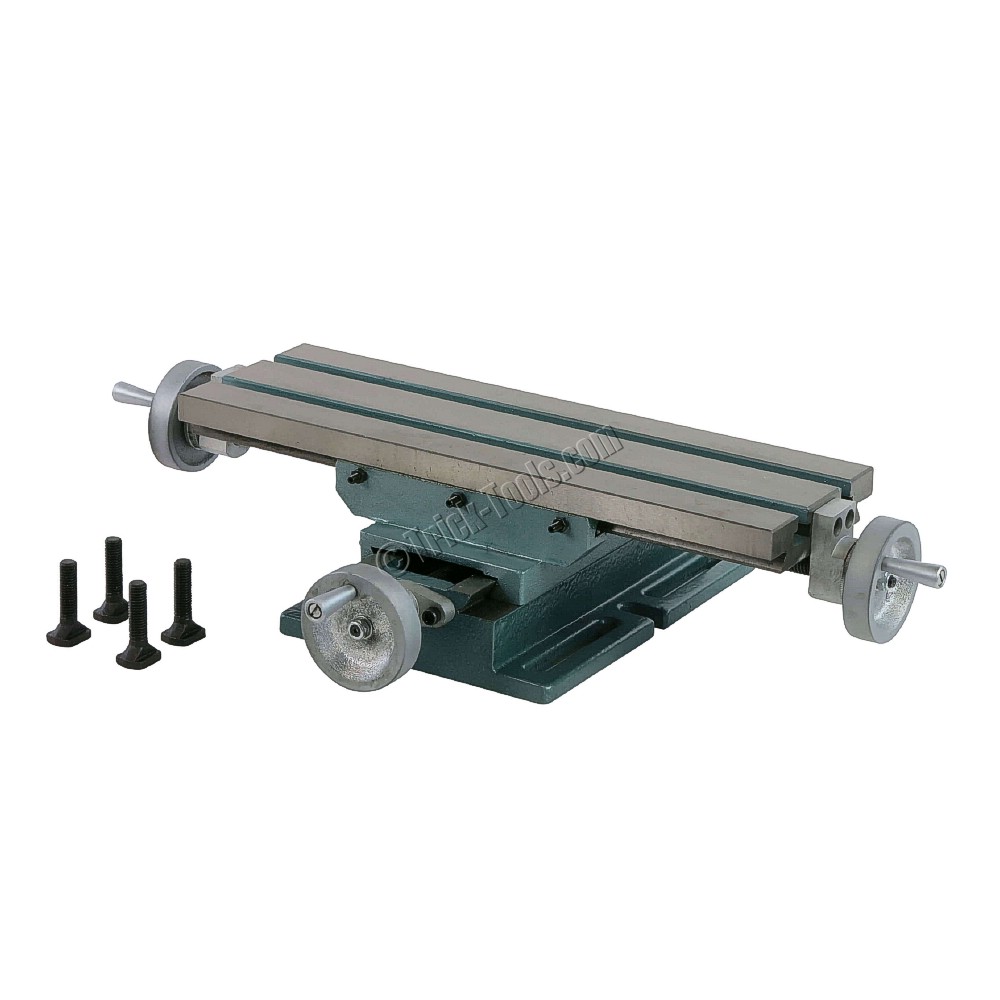

Setting up a milling table with a drill press requires careful attention. A proper setup ensures accuracy and safety during your work. Follow some key steps to install the milling table correctly. This makes your machining tasks smoother and more efficient.

Proper Alignment Techniques

Start by placing the milling table on the drill press base. Check that the table surface is flat and level. Use a precision square or a dial indicator to align the table edges with the drill bit. Adjust the table until it is perfectly parallel to the drill press spindle.

Align the table in both the X and Y directions. Tighten the adjustment screws lightly to hold the position. Double-check alignment before fully securing the table. Proper alignment reduces errors during milling and drilling.

Securing The Milling Table Safely

Use bolts or clamps to fix the milling table firmly to the drill press base. Ensure the fasteners are tight but do not overtighten. Overtightening can damage the table or drill press. Check the manufacturer’s instructions for recommended torque settings.

Make sure the table does not move or wobble after securing. A stable milling table improves precision and prevents accidents. Regularly inspect the fasteners during use to maintain safety and accuracy.

Credit: www.trick-tools.com

Best Practices For Operation

Operating a milling table with a drill press requires careful attention. Following best practices improves safety and accuracy. These tips help you get the best results from your setup.

Tool Selection And Speed Settings

Choose the right cutting tool for your material and task. Use end mills or cutters designed for milling. Avoid drill bits as they are not made for side cutting.

Set the drill press speed according to the tool and material. Use slower speeds for harder metals. Faster speeds work well for softer materials like wood or plastic. Always check the tool manufacturer’s recommendations.

Workpiece Handling And Clamping

Secure your workpiece firmly on the milling table. Use strong clamps or a vise to prevent movement. Loose parts can cause poor cuts or accidents.

Double-check the clamping before you start. The workpiece should not shift under pressure. Proper clamping ensures clean, precise milling and keeps you safe.

Alternative Solutions

Using a milling table with a drill press can be tricky. The setup may not offer enough control or precision for detailed work. Many users find that alternative tools or upgrades provide better results. Exploring these options can save time and improve your project quality.

Dedicated Mini Milling Machines

Mini milling machines are designed for precise cutting and shaping. They offer more control than a drill press with a milling table. These machines have adjustable speeds and better stability. Ideal for small workshops and hobbyists, they handle detailed tasks easily. Investing in a mini mill often leads to better accuracy and smoother finishes.

Upgrading Drill Press Accessories

Upgrading your drill press with better accessories can improve its milling ability. Adding a more precise vise or a rotary table helps with accuracy. Specialized drill press columns or enhanced tables increase stability. These upgrades make the drill press more versatile. Still, keep in mind, they may not match the control of a dedicated milling machine.

Frequently Asked Questions

Can You Attach A Milling Table To A Drill Press?

Yes, you can attach a milling table to a drill press. It allows precise X-Y movement for milling tasks. However, ensure the drill press is sturdy and powerful enough to handle milling forces safely.

Is A Drill Press Suitable For Light Milling Work?

A drill press can handle light milling with a proper milling table. It’s best for small, less demanding milling jobs rather than heavy industrial work. Use low speeds and steady feed for better results.

What Are The Limitations Of Using A Drill Press As A Mill?

Drill presses lack the rigidity and power of dedicated mills. They have limited speed control and less precise depth adjustment. This restricts their use to light milling and small projects only.

How To Improve Milling Accuracy On A Drill Press?

Use a high-quality milling table with fine adjustment screws. Secure workpieces firmly and use sharp, appropriate cutters. Consistent feed and slow speeds enhance milling accuracy on a drill press.

Conclusion

Using a milling table with a drill press can improve your work’s accuracy. It adds stability and helps hold your material firmly. This setup works well for small projects and light milling tasks. Always check that your drill press can handle the added weight and stress.

Keep safety in mind by securing everything properly before starting. Milling tables do not replace full milling machines but offer useful support. This option suits hobbyists and beginners wanting more control in their projects. Try it carefully and see how it fits your needs.