Are you curious about how much power your cordless drill really has? Understanding torque is key to knowing if your drill can handle tough jobs or just light tasks.

You’ll discover exactly what torque means for your drill and how it affects your work. By the end, you’ll know how to pick the right drill that matches your needs and makes every project easier. Keep reading, because the right torque can make all the difference in your DIY success!

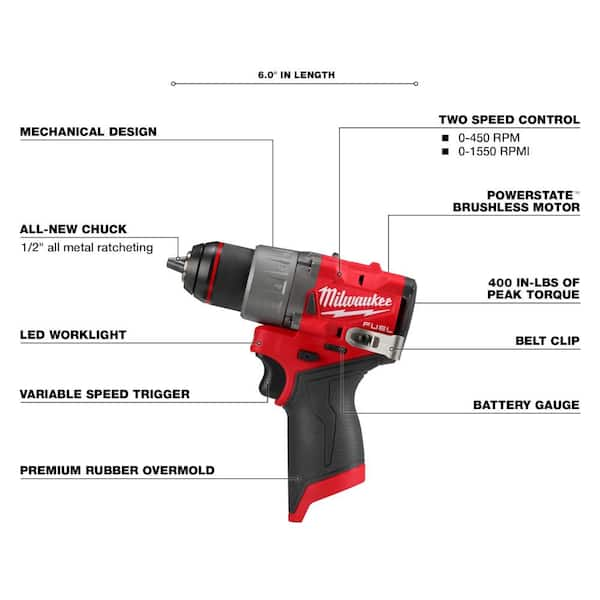

Credit: www.homedepot.com

Torque Basics

Torque is a key factor in cordless drills. It tells us how much force the drill can apply. This force helps the drill turn screws or drill holes easily.

Understanding torque helps you pick the right drill for your tasks. It affects how well the drill performs on different materials.

What Torque Means

Torque measures twisting force. It is usually shown in inch-pounds or Newton-meters. Higher torque means more power to turn screws or drill bits.

Think of torque as how hard the drill can push while spinning. More torque means the drill can handle tougher jobs.

Why Torque Matters In Drills

Torque helps the drill work on various materials. Soft wood needs less torque. Hard wood or metal needs more torque.

Too little torque can stop the drill from working properly. Too much torque can damage screws or the material.

Choosing the right torque level makes your work faster and easier. It also protects your tools and materials from damage.

Credit: jcb-tools.com

Measuring Torque

Measuring torque is important to understand a cordless drill’s power. Torque shows how much twisting force the drill can apply. It helps know if the drill can handle tough jobs or only light tasks. Accurate measurement ensures you pick the right drill for your needs.

Torque is not just a number. It has specific units and testing methods. Knowing these details helps compare different drills better. Let’s explore how torque is measured and expressed.

Units Of Torque

Torque is measured in units that show force times distance. The most common unit is the Newton-meter (Nm). It means how many newtons of force act on a lever one meter long. Another unit is the inch-pound (in-lb), used mainly in the US. Both units help describe how strong a drill’s motor is.

Manufacturers usually list torque in Nm for cordless drills. This unit is easy to understand and compare. Some drills show both Nm and in-lb to serve global customers. Knowing these units helps you read drill specs correctly.

How Torque Is Tested

Torque testing uses special machines. These machines apply force to the drill’s chuck. They measure how much twisting force the drill produces before it stalls. The test often uses a torque meter or dynamometer.

The drill runs at different speeds during testing. This checks torque at low and high speeds. The highest torque recorded is the drill’s maximum torque. This number helps users know the drill’s true strength.

Testing also checks torque under real working conditions. This means using screws or bolts similar to actual tasks. This method shows how the drill performs in daily use. It gives a better idea than just motor specs alone.

Torque Range In Cordless Drills

Torque is a key factor in cordless drills. It shows how much twisting force the drill can provide. Different tasks need different torque levels. Knowing the torque range helps pick the right drill for your job.

Torque is measured in inch-pounds (in-lbs) or Newton-meters (Nm). Cordless drills have a wide torque range. This range depends on the drill’s design and power. Here are the common torque categories for cordless drills.

Light-duty Models

Light-duty drills offer low torque, usually under 200 in-lbs. They are good for small tasks like assembling furniture or drilling into soft wood. These models are lightweight and easy to handle. Perfect for beginners or occasional use.

Mid-range Drills

Mid-range drills provide torque between 200 and 500 in-lbs. They handle a variety of tasks like drilling into hardwood and driving larger screws. These drills balance power and portability. Suitable for most DIY projects and home repairs.

Heavy-duty Options

Heavy-duty cordless drills deliver over 500 in-lbs of torque. They work well on tough materials like metal and concrete. These drills are built for professionals and serious DIYers. They offer more power but tend to be heavier and costlier.

Factors Affecting Drill Torque

Torque is the twisting force a cordless drill uses to turn screws or drill holes. Several factors affect how much torque a drill can deliver. Understanding these factors helps in choosing the right drill for your tasks.

Battery Power

The battery provides energy to the drill’s motor. Higher voltage batteries usually offer more torque. Lithium-ion batteries hold charge longer and deliver steady power. Battery capacity also affects torque; larger capacity means longer use and better performance.

Motor Design

The motor converts electrical energy into mechanical force. Brushless motors are more efficient and produce higher torque. They also last longer and need less maintenance. Brushed motors are cheaper but may have lower torque and shorter life.

Gearbox Configuration

The gearbox controls speed and torque output. Multiple gears allow switching between high speed and high torque. A lower gear setting increases torque but reduces speed. A well-designed gearbox balances power and control for different tasks.

Choosing Torque For Your Needs

Choosing the right torque for your cordless drill matters. Torque affects how well the drill performs different tasks. Too little torque can slow your work. Too much torque might damage screws or materials. Understand your needs before picking a drill. This helps you avoid problems and saves time.

Home Use

For home projects, low to medium torque is enough. Tasks like hanging pictures or assembling furniture need less power. A drill with 100 to 300 inch-pounds torque works well. It handles most household jobs without causing damage. Lightweight drills also make work easier and less tiring.

Professional Use

Professionals need higher torque for tough jobs. Construction and carpentry often require 300 to 600 inch-pounds or more. Strong torque drives large screws and drills through hard materials. A durable drill with adjustable torque settings is best. It offers control and power for varied tasks.

Specialized Applications

Some tasks need very specific torque levels. Automotive repair or metalworking may require precise torque control. Cordless drills with digital torque settings suit these jobs. They prevent over-tightening or stripping screws. Choose a drill designed for the exact work you do.

Comparing Torque Across Brands

Torque is a key factor when choosing a cordless drill. Different brands offer varied torque levels. Comparing these helps find the right drill for your needs. Torque affects how well a drill can handle tough jobs. Higher torque means more power to drive screws or drill through hard materials.

Top Brands Overview

Brands like DeWalt, Makita, and Bosch are popular choices. DeWalt drills usually have torque ranging from 300 to 600 inch-pounds. Makita offers models with torque between 300 and 500 inch-pounds. Bosch drills often deliver torque around 350 to 450 inch-pounds. Each brand balances power, size, and weight differently. This affects user comfort during long tasks.

Torque Vs Price

Higher torque often means a higher price tag. Entry-level drills may have torque below 300 inch-pounds and cost less. Mid-range drills provide around 400 inch-pounds and fit most DIY jobs. Premium drills with over 500 inch-pounds suit heavy-duty work and cost more. Choosing depends on your budget and tasks. Spending more does not always mean better for simple projects.

Improving Drill Torque

Improving the torque of a cordless drill helps you work faster and with less effort. Torque is the twisting force that makes the drill turn screws and drill holes. More torque means the drill can handle tougher jobs. You can boost torque in simple ways. These methods keep your drill strong and ready for any task.

Upgrading Batteries

Battery power affects how much torque your drill can produce. Older batteries may lose strength over time. Using a new, high-capacity battery can give your drill more power. Choose batteries with higher voltage for better torque. Lithium-ion batteries hold a charge longer and deliver steady power. This upgrade helps your drill run at peak performance.

Maintaining Your Drill

Keeping your drill clean and well-oiled improves torque. Dust and debris inside the drill can slow down its motor. Regularly remove dirt from vents and moving parts. Check the gears and apply light machine oil if needed. Tighten loose screws to avoid power loss. A well-maintained drill works smoothly and delivers strong torque every time.

Credit: www.ozito.com.au

Future Trends In Drill Torque

The future of cordless drill torque is promising and full of innovation. Technology is improving fast, making drills stronger and smarter. Users can expect better performance without extra weight or size. These advances will help both hobbyists and professionals work more efficiently.

Advancements In Battery Tech

Batteries are becoming more powerful and lighter. New battery types store more energy and last longer. This means drills can deliver higher torque for extended periods. Faster charging times reduce downtime during projects. Better batteries also keep drills cooler and safer.

Smart Torque Control

Smart torque control allows drills to adjust power automatically. Sensors detect resistance and change torque in real-time. This prevents over-tightening or stripping screws. It also protects drill motors from damage. Users get precise control and better results on all tasks.

Frequently Asked Questions

What Is The Average Torque Of A Cordless Drill?

Most cordless drills offer torque between 150 to 600 inch-pounds. This range suits light to medium-duty tasks effectively. Higher torque models handle tougher materials like hardwood and metal. Choosing the right torque depends on your project needs and drill specifications.

How Does Torque Affect Cordless Drill Performance?

Torque determines a drill’s twisting force, impacting its ability to drive screws or drill holes. Higher torque means better performance on dense materials. Low torque drills are ideal for delicate tasks. Proper torque ensures efficiency, prevents bit stripping, and extends tool life.

Can Cordless Drills Deliver Enough Torque For Heavy Tasks?

Yes, many cordless drills provide sufficient torque for heavy-duty jobs. Models with brushless motors and higher voltage (18V or 20V) excel at tough applications. However, for extremely demanding tasks, consider corded drills or impact drivers for maximum torque and power.

Why Does Torque Vary Among Cordless Drill Models?

Torque varies due to motor type, battery voltage, and gear design. Brushless motors typically deliver higher torque and efficiency. Higher voltage batteries provide more power, increasing torque output. Gear mechanisms also influence torque by adjusting speed and force balance.

Conclusion

Cordless drills come with different torque levels for various jobs. Higher torque means better power for tough tasks. Lower torque suits light work and delicate materials. Choosing the right torque helps you work efficiently and safely. Always match drill torque to your project needs.

This ensures good results and saves time. Understanding torque makes your drilling easier and more precise. Keep these points in mind when picking a cordless drill. You will enjoy smoother and faster work every time.