Have you ever been in the middle of a project when your cordless drill suddenly dies? It’s frustrating, right?

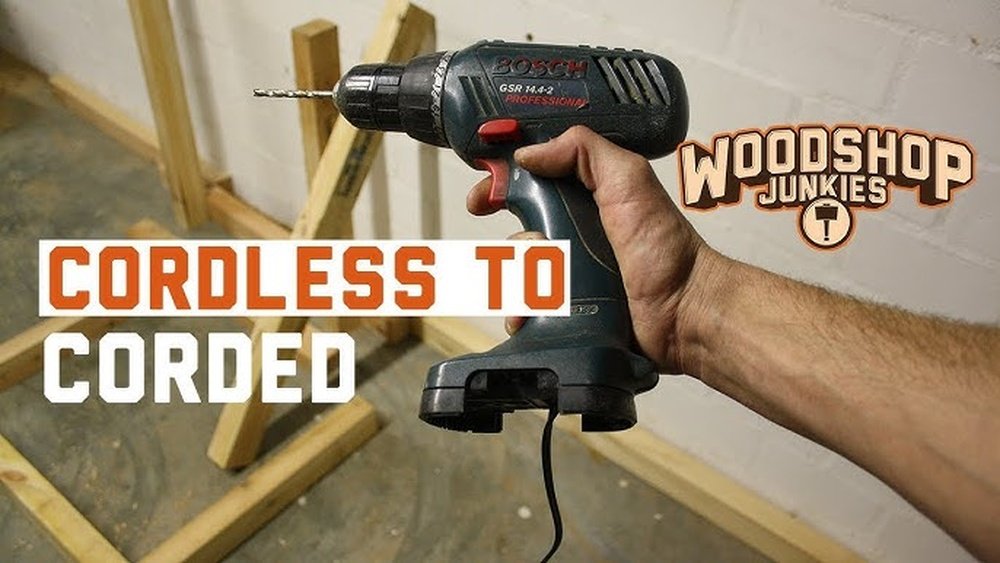

What if you could turn that cordless drill into a corded one and never worry about battery life again? You’re probably wondering if it’s even possible or worth the effort. You’ll discover the truth about converting your cordless drill to corded power.

By the end, you’ll know exactly what to consider and whether this DIY hack can save you time, money, and headaches. Keep reading to find out!

Credit: www.instructables.com

Cordless Vs Corded Drills

Choosing between cordless and corded drills depends on your needs. Both have unique features that suit different tasks. Understanding their differences helps in making the right choice for your projects.

Key Differences

Cordless drills run on batteries. They offer freedom to move without limits. Corded drills need a power outlet. They provide constant power without recharging.

Cordless models are lighter and more portable. Corded drills tend to be heavier but more powerful. Battery life limits cordless drill work time. Corded drills can work as long as plugged in.

Corded drills generally have higher torque. Cordless drills are improving but may not match corded power yet. Corded drills need no downtime. Cordless drills require charging breaks.

Pros And Cons

Cordless drills offer great portability and ease of use. No cords mean less hassle and better reach in tight spaces. Downsides include limited run time and battery wear over time.

Corded drills deliver steady power and more torque for tough jobs. They do not need charging and are usually less expensive. The cord can limit movement and cause inconvenience.

Cordless drills are perfect for quick jobs and light work. Corded drills suit heavy-duty tasks and long projects. The choice depends on your work style and project needs.

Credit: www.instructables.com

Reasons To Convert

Converting a cordless drill to corded can solve many problems. Cordless drills run on batteries that lose power fast. This limits how long you can work without stopping. A corded drill offers constant power without the need to recharge. This change can help save time and reduce frustration.

Some drills lose battery life quickly or need expensive replacements. Turning these tools into corded drills can extend their use. This makes sense for those who use drills often or for long jobs. It also helps when a cordless drill’s battery stops working well.

When Conversion Makes Sense

Conversion fits best for drills with dead or weak batteries. It also works well for people who drill for hours daily. Those who dislike waiting for batteries to recharge find it useful. Some drills have good motors but poor battery life. Changing to corded power can bring new life to these tools.

People who work in workshops or fixed locations benefit most. They can plug the drill in and work without breaks. This is helpful when a project needs steady, long-lasting power. The conversion lets users avoid carrying extra batteries or chargers.

Common Use Cases

Home renovation projects often need long drill time. Corded drills keep running without stopping for battery changes. DIY enthusiasts find this helpful for building furniture or fixing walls. Gardeners using drills for outdoor tasks also gain from steady power.

Professionals like carpenters and electricians use drills daily. They need tools that run nonstop on job sites. Corded drills help avoid delays caused by dead batteries. Workshop owners may convert drills to save money on batteries.

Required Tools And Materials

Converting a cordless drill to corded requires specific tools and materials. You need the right equipment to do the job safely and correctly. Gather everything before starting to avoid interruptions. Proper preparation makes the process easier and faster.

Essential Equipment

You will need a power cord with a plug suited for your area. A soldering iron and solder help connect wires securely. Wire strippers remove insulation from the power cord’s wires. Electrical tape or heat shrink tubing protects exposed wires. A screwdriver is necessary to open the drill casing. A multimeter checks electrical connections and voltage levels. A drill or Dremel tool may be useful to modify the drill casing.

Safety Gear

Safety glasses protect your eyes from sparks and debris. Insulated gloves reduce the risk of electric shock. Work in a well-ventilated area to avoid inhaling fumes from soldering. Use a stable work surface to prevent accidents. Keep a fire extinguisher nearby for emergencies. Wearing long sleeves helps protect your skin from burns.

Step-by-step Conversion Process

Converting a cordless drill to a corded one can save battery troubles. The process involves careful steps to ensure safety and functionality. Follow this step-by-step guide to make the change correctly and safely.

Disassembling The Drill

First, remove the battery from the drill. Use a screwdriver to open the drill casing. Keep all screws in a safe place. Gently separate the drill parts to access the motor and wiring. Avoid pulling on wires to prevent damage.

Wiring For Power Supply

Locate the motor’s power terminals inside the drill. Cut the battery wires close to the terminals. Strip the ends of the wires to expose the metal. Attach new wires that connect to a power cord. Use electrical tape or solder to secure connections.

Securing The Cord

Choose a power cord with the right voltage rating. Feed the cord through a small hole in the drill casing. Use a strain relief clamp to hold the cord firmly. This prevents the cord from pulling loose during use. Close the drill casing carefully around the cord.

Testing The Converted Drill

Plug the drill into a power outlet with the correct voltage. Turn the drill on and check for smooth operation. Listen for unusual noises or smells. If all works well, the conversion is complete. Unplug the drill before any adjustments or repairs.

Safety Precautions

Converting a cordless drill to a corded one involves working with electricity. Safety is the top priority. Taking proper precautions prevents accidents and damage. Understanding the risks helps you work carefully and confidently.

Electrical Safety Tips

Always unplug the drill before starting any work. Use insulated tools to avoid electric shocks. Check wires for damage or exposed metal. Never touch wires with wet hands. Work in a dry area to reduce shock risk. Use a voltage tester to confirm no power is running. Wear rubber-soled shoes and avoid standing on metal surfaces.

Avoiding Common Mistakes

Do not force wires into connectors. Ensure all connections are tight and secure. Avoid mixing wires from different power sources. Do not ignore the drill’s voltage rating. Using the wrong voltage can cause overheating. Label wires clearly to avoid confusion. Double-check your setup before plugging in the drill.

Credit: www.youtube.com

Troubleshooting Tips

Troubleshooting is key when converting a cordless drill to corded. Problems can happen during or after the conversion. Knowing common issues helps fix them fast. This saves time and effort. Here are some simple tips to solve common problems.

Power Issues

Power problems are common after conversion. Check the power source first. Make sure the cord is plugged in tightly. Inspect the wire for cuts or damage. A loose connection can stop the drill from working.

Test the power outlet with another device. This confirms if the outlet works well. If the drill still does not power on, check the internal wiring. Look for loose or broken wires. Fix any damaged parts carefully.

Mechanical Problems

Mechanical issues can block drill operation. Listen for strange sounds when turning it on. These can mean gears are stuck or worn out. Check the chuck and motor for dirt or debris. Clean these parts gently for smooth motion.

Make sure all screws and bolts are tight. Loose parts can cause vibration or noise. If the drill feels hot quickly, the motor might be overloaded. Avoid running it for long periods without breaks.

Alternatives To Conversion

Converting a cordless drill to corded is not always practical or safe. Many users want a steady power source but face challenges with conversion. There are simpler and safer alternatives to consider. These options keep your work smooth without complex modifications.

Using Cordless Drill With Extended Battery

One easy way to avoid conversion is using an extended battery. These batteries last longer than standard ones. You get more work time without stopping to recharge. They fit most cordless drills and offer good power.

Extended batteries are lightweight and easy to carry. No need for cords, making your work flexible. This option keeps your drill portable and ready for any job.

Buying A Corded Drill

Buying a corded drill is a direct solution for constant power. Corded drills plug into any outlet and run without stopping. They are often more powerful for heavy tasks.

Corded drills come in many sizes and power levels. Choose one that fits your needs and budget. This saves time and avoids risks linked to DIY conversions.

Cost And Time Considerations

Changing a cordless drill to a corded one involves thinking about both money and time. These factors help decide if the change is worth it or if buying a new drill is better. Understanding costs and the time needed makes the project clearer and easier to plan.

Expense Breakdown

Converting a cordless drill requires parts like a power cord and connectors. These parts may cost less than a new drill but add up quickly. There is also a risk of damaging the drill, which could lead to extra costs. Sometimes, buying a new corded drill offers better value for money.

Time Investment

The process needs time to gather parts and tools. You must carefully open the drill and connect the power cord. This task can take a few hours, especially without experience. Mistakes during conversion can cause delays or require redo. Consider your time as part of the project cost.

Frequently Asked Questions

Can You Convert A Cordless Drill To Corded Power?

Yes, you can convert a cordless drill to corded by wiring it to a compatible power adapter. This requires basic electrical skills and safety precautions.

What Tools Are Needed For Cordless To Corded Conversion?

You need a power adapter, soldering tools, wire cutters, and electrical tape. Ensure the adapter matches the drill’s voltage and current requirements.

Is Converting Cordless Drills Cost-effective?

Converting can save money if the drill is valuable. However, buying a new corded drill might be safer and more reliable in the long run.

Will Converting Affect The Drill’s Performance?

If done correctly, performance remains stable. Using the correct power supply ensures consistent speed and torque without battery limitations.

Conclusion

Converting a cordless drill to corded is possible but not always simple. It needs some tools and technical skills. Safety matters most during any changes. Sometimes buying a corded drill is easier and safer. Think about how often you use the drill and what power you need.

Choose the best option that fits your work and budget. This way, you get the right tool without trouble.