Have you ever wondered if your impact driver can wear out from too many hours of use? You rely on this powerful tool for tough jobs, but how much is too much?

Knowing when your impact driver is reaching its limit can save you time, money, and frustration. You’ll discover the signs of wear, how to extend your tool’s life, and when it’s time to replace it. Keep reading to make sure your impact driver stays ready for every project you tackle.

Credit: www.ebay.com

Lifespan Of Impact Drivers

Impact drivers are powerful tools designed for tough jobs. Their lifespan depends on many things. Knowing how long your impact driver lasts helps you plan repairs or replacements. It also ensures safety and efficiency during work. Let’s explore the typical lifespan and what affects it.

Average Usage Hours

Most impact drivers last between 5,000 and 10,000 hours of use. This range varies by brand and model quality. Professional-grade tools often reach the higher end of this range. Home-use drivers may wear out faster with heavy use. Tracking hours helps avoid unexpected breakdowns.

Factors Affecting Durability

Frequent overuse strains the motor and reduces lifespan. Using the right bits and avoiding overload protect the tool. Regular cleaning keeps dust and debris from causing damage. Battery care also plays a big role for cordless models. Storing the driver in a dry place prevents rust and corrosion. Proper use and maintenance extend the life of any impact driver.

Credit: www.pawnamerica.com

Common Signs Of Wear

An impact driver can work hard for many hours. Over time, it shows signs of wear. These signs tell you that the tool may need repair or replacement. Spotting these signs early helps keep your work safe and efficient.

Reduced Power Output

Your impact driver may lose strength after long use. It may take longer to drive screws or bolts. The motor might feel weaker. This drop in power means the internal parts are wearing out.

Unusual Noises

Strange sounds can come from a worn impact driver. Grinding, rattling, or squeaking noises are common. These sounds point to loose or damaged parts inside the tool. Ignoring these noises can cause more damage.

Overheating Issues

The impact driver may get very hot quickly. Overheating happens when the motor works too hard. This can happen if parts are worn or dirty. Overheating can shorten the tool’s life and cause failure.

Visible Physical Damage

Look for cracks, dents, or worn paint on the tool body. Broken or loose parts are a clear warning. Physical damage shows the tool has faced heavy use or accidents. It may not work safely or well anymore.

Effects Of Overuse

Using an impact driver too much can cause problems. Overuse affects how well the tool works. It can lead to parts wearing out faster. Understanding these effects helps you keep your tool in good shape.

Motor Degradation

The motor inside the impact driver can wear down with too many hours. Heat builds up and parts start to break. This makes the motor weaker and less powerful. Eventually, the driver may stop working properly.

Battery Performance Decline

Long use also harms the battery. Batteries lose charge faster after many hours of work. They take longer to recharge and hold less power. This reduces the time you can use the driver before charging again.

Impact On Tool Accuracy

Overuse can make the tool less accurate. The driver may not hit screws as precisely. This causes slipping or damage to the screw head. Poor accuracy makes tasks harder and can ruin materials.

Credit: www.reddit.com

Maintenance Tips To Extend Life

Keeping an impact driver in good shape helps it last longer. Regular care prevents problems and saves money. Simple steps can protect your tool from wear and tear. Follow these tips to keep your driver working well for many hours.

Regular Cleaning

Dust and dirt can clog the driver’s moving parts. Clean the tool after each use. Use a soft brush or cloth to remove debris. Avoid water to stop rust and damage. Clean vents to keep the motor cool and efficient.

Proper Storage

Store the impact driver in a dry, cool place. Avoid damp or hot areas that can harm the tool. Use the original case or a sturdy box for protection. Keep batteries separate if not using the tool for a long time. This prevents battery drain and damage.

Routine Inspections

Check the impact driver regularly for loose parts or wear. Look at the chuck, trigger, and battery connections. Tighten any loose screws or bolts. Replace worn parts before they cause bigger problems. Early checks help catch issues early and keep the tool safe.

When To Replace Your Impact Driver

Knowing when to replace your impact driver is key to keeping your work smooth and safe. An impact driver can last many hours, but it will wear down over time. Recognizing signs of wear helps avoid problems on the job. This section guides you through important factors to consider before deciding to replace your tool.

Cost Of Repairs Vs Replacement

Check repair costs before fixing your impact driver. Sometimes, fixing old parts costs nearly as much as buying new. New tools often come with better features and warranties. Spending more on repairs may not be smart if the tool is old. Compare prices carefully to make the best choice.

Safety Concerns

Old impact drivers can become unsafe. Worn parts might break during use and cause injuries. Electrical issues can also be a risk. Using a tool past its prime puts you in danger. Replace your impact driver if safety is in question.

Performance Expectations

Over time, impact drivers lose power and speed. You may notice slower work and weaker torque. This affects your overall job quality. If your tool struggles to do basic tasks, it may be time for a new one. Keep performance high for the best results.

Choosing A New Impact Driver

Choosing a new impact driver can feel tricky. Many options exist, and each has its strengths. Picking the right one saves time and effort on your projects. It also ensures the tool lasts long and works well for your needs.

Key Features To Look For

Power is essential. Check the voltage and torque rating. Higher torque means more driving force. Battery life matters too. Longer battery life means less charging and more work. Look for a comfortable grip. A good grip reduces hand fatigue. Also, consider the size and weight. Smaller, lighter drivers are easier to handle in tight spaces.

Budget Considerations

Set a budget before buying. Impact drivers vary widely in price. More expensive models may offer better features and durability. Yet, affordable models often work well for basic tasks. Think about how often you will use it. For occasional use, a lower-cost option might be enough. For frequent use, investing in quality pays off.

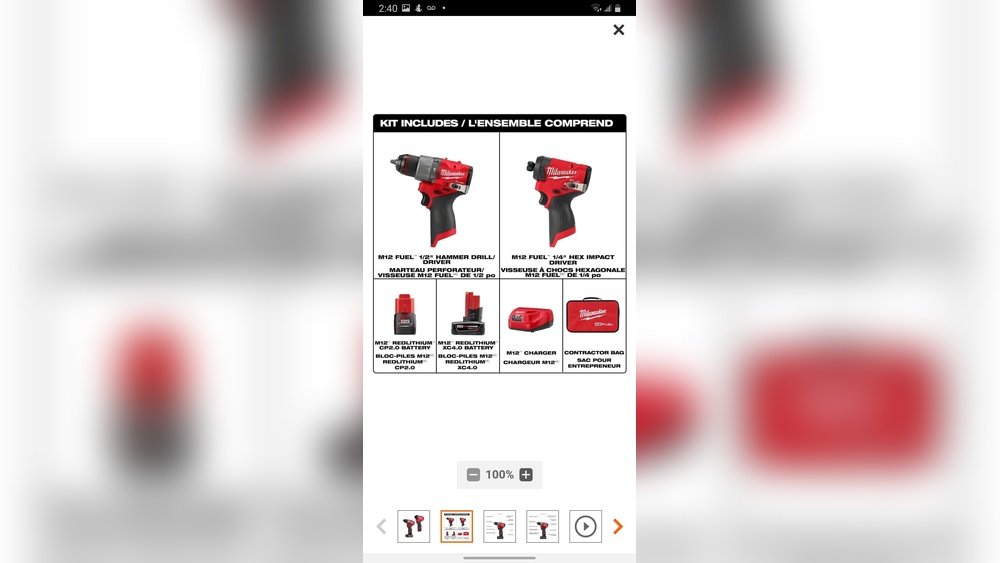

Top Brands And Models

Some brands have a strong reputation for quality. Brands like DeWalt, Makita, and Milwaukee are popular. They offer reliable tools and good warranties. Models like DeWalt DCF887, Makita XDT16, and Milwaukee M18 are well-reviewed. These drivers balance power, battery life, and comfort. Choosing a trusted brand reduces the risk of defects and poor performance.

Frequently Asked Questions

Can An Impact Driver Have Too Many Hours?

Yes, an impact driver can wear out with excessive hours. Overuse causes motor and battery strain, reducing performance and lifespan.

How Do Hours Affect Impact Driver Durability?

More hours mean more wear on internal parts. Prolonged use without breaks leads to overheating and faster component failure.

Is There A Recommended Usage Limit For Impact Drivers?

Manufacturers suggest regular breaks and moderate use. Avoid continuous heavy-duty tasks to extend tool life and maintain efficiency.

Can Overusing An Impact Driver Void Warranty?

Excessive use or abuse may void the warranty. Follow manufacturer guidelines to ensure your warranty remains valid.

Conclusion

An impact driver can last many hours with proper care. Regular maintenance helps keep it working well. Overusing it without breaks might cause wear and tear. Watch for signs of overheating or reduced power. Taking breaks and cleaning parts extends its life.

Remember, even the best tools need rest and care. Use your impact driver wisely for long-lasting performance.