Are you struggling to get the perfect torque for your drilling projects? Getting the right torque is crucial to avoid damaging your materials or tools.

Imagine saving time, preventing costly mistakes, and making your work smoother with just a simple calculation. That’s where a Drill Torque Calculator comes in. This tool can change the way you work by giving you precise torque values every time.

Keep reading to discover how you can easily master your drilling tasks and boost your efficiency with the right torque settings.

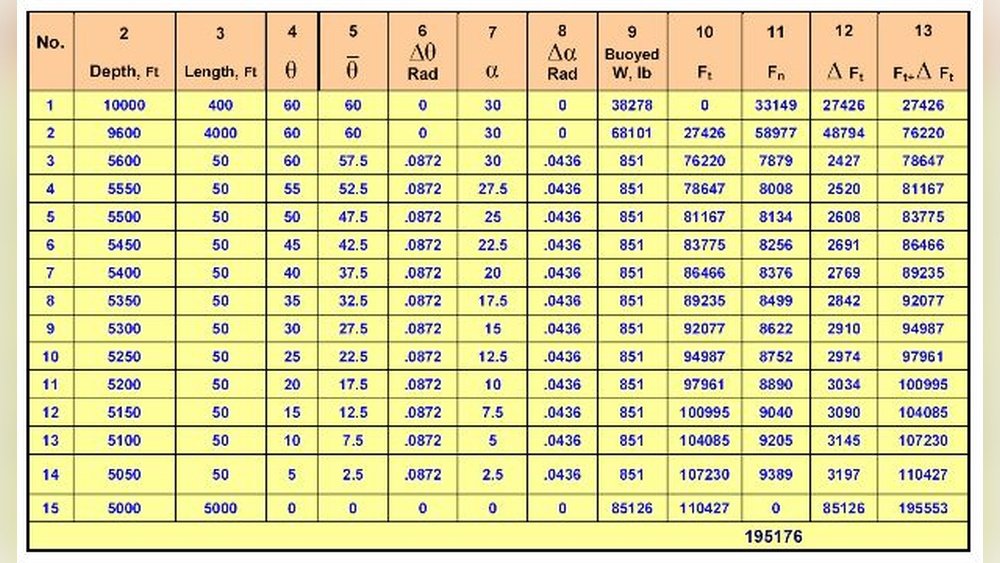

Credit: www.drillingmanual.com

What Drill Torque Means

Drill torque is a key factor in drilling tasks. It shows how much twisting force a drill can apply. This force helps the drill bit cut through materials like wood, metal, or plastic.

Knowing about drill torque helps you pick the right drill for each job. It also prevents damage to the drill or the work surface. Understanding torque improves both safety and efficiency.

Basics Of Torque In Drilling

Torque is the force that causes rotation. In drilling, it is the twisting power the drill motor creates. The drill bit turns because of torque, making holes in materials.

More torque means the drill can handle tougher jobs. Less torque is fine for soft materials or small screws. Torque is measured in units like Newton-meters (Nm) or inch-pounds.

Importance Of Accurate Torque Measurement

Measuring torque correctly keeps the drill working well. Too much torque can break the drill bit or damage the material. Too little torque means the drill can’t finish the job properly.

Accurate torque helps control how fast and deep the drill goes. It also saves battery life in cordless drills. A drill torque calculator helps find the right torque for each task.

Credit: www.drillingformulas.com

Factors Affecting Drill Torque

Drill torque is the twisting force needed to turn a drill bit into a material. Several factors influence this force. Understanding these factors helps in selecting the right drill settings and tools. It also ensures safety and efficiency during drilling.

Material Type And Hardness

The type of material being drilled affects torque greatly. Hard materials like steel need more torque than soft materials like wood. The hardness determines how much force is required to cut through. Tough materials slow down the drilling process and increase torque.

Drill Bit Size And Type

Larger drill bits need more torque to rotate. The size affects the surface area in contact with the material. Different drill bit types suit different materials. For example, twist bits work well with metals, while spade bits are ideal for wood. Using the correct bit reduces torque and wear.

Speed And Feed Rate

Speed is how fast the drill bit spins. Feed rate is how fast the bit moves into the material. High speed with a slow feed rate lowers torque but may cause overheating. A balanced speed and feed rate prevent damage and keep torque stable.

How Drill Torque Calculators Work

Drill torque calculators help measure the force needed to turn a drill bit during drilling. They simplify complex math by using input data to give quick, accurate results. Understanding how these calculators work makes it easier to use them effectively.

Input Parameters Required

The calculator needs specific information to work correctly. Common inputs include drill bit diameter, material type, and drilling speed. Some tools also ask for feed rate and depth of cut. These details affect the torque calculation and final result.

Calculation Methods

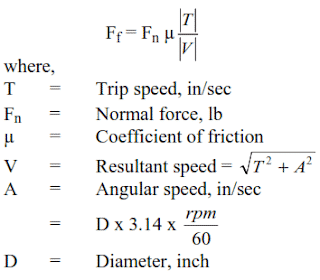

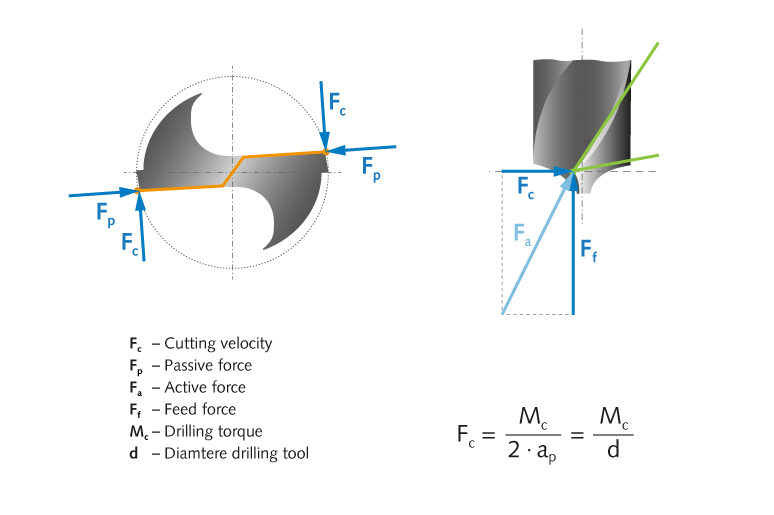

Calculators use formulas based on physics and engineering principles. They calculate the resistance the drill bit faces while cutting. Torque equals the force multiplied by the radius of the drill bit. Some calculators use more advanced methods for better accuracy.

Output Interpretation

The result shows the torque value in units like Newton-meters or inch-pounds. This value helps users choose the right drill motor and settings. Understanding the output prevents tool damage and improves drilling efficiency. Clear numbers make decisions easier and safer.

Benefits Of Using A Drill Torque Calculator

Using a drill torque calculator brings many benefits to your drilling projects. It helps you work smarter and safer. You get accurate results without guesswork. This tool supports better decisions on the job. Small changes can lead to big improvements.

Enhanced Precision

A drill torque calculator gives exact torque values. It removes the risk of over-tightening or under-tightening screws. Precise torque means stronger and more reliable joints. It improves the quality of your work. You avoid mistakes that cause damage or failure.

Improved Efficiency

Calculating torque fast saves time on site. You do not waste time testing or adjusting tools. The calculator guides you to the right torque from the start. This speeds up drilling and assembly tasks. It helps meet project deadlines with ease.

Reduced Tool Wear

Correct torque settings protect your drill and bits. Less strain on tools means they last longer. Avoiding too much force prevents breakage and wear. This lowers maintenance and replacement costs. A drill torque calculator helps extend tool life.

Steps To Use A Drill Torque Calculator

Using a drill torque calculator helps you find the right torque for drilling tasks. It makes drilling safer and more efficient. Follow these simple steps to get accurate results and use them properly.

Gathering Necessary Data

Start by collecting all data needed for the calculator. This includes drill bit size, material type, and drilling speed. Knowing the material hardness and drill diameter is important. These values affect the torque required. Check your drill and project details carefully.

Entering Values Correctly

Input the data into the calculator fields exactly as you collected. Use correct units like inches, millimeters, or RPM. Avoid mistakes like mixing units or typing wrong numbers. Double-check each entry before submitting. Accurate input ensures correct torque calculation.

Applying Results To Drilling

Use the calculated torque to set your drill’s torque control. This avoids drilling too hard or too soft. Adjust your drill settings according to the recommended torque. It helps protect your drill and work material. Follow the torque value during your drilling process for best results.

Credit: www.kistler.com

Common Mistakes To Avoid

Using a drill torque calculator can save time and improve results. Avoiding common mistakes helps get accurate torque readings. Mistakes often cause wrong data and poor tool performance. Learn the key errors to prevent for better drilling outcomes.

Incorrect Data Entry

Entering wrong numbers leads to wrong torque values. Double-check drill size, speed, and material type. Small errors can cause big problems in calculations. Use the correct units for all inputs. Always review data before calculating torque.

Ignoring Material Variations

Different materials need different torque settings. Soft materials require less torque than hard ones. Ignoring this can break the drill or damage the workpiece. Know the material type before setting the torque. Adjust calculations to fit the material’s needs.

Overlooking Maintenance Needs

Worn or dirty drills change torque requirements. A dull drill needs more torque to cut. Skip maintenance and torque readings become inaccurate. Clean and sharpen drills regularly for best results. Proper tool care keeps torque calculations reliable.

Top Drill Torque Calculators Available

Drill torque calculators help measure the force needed to turn a drill bit. They are essential for choosing the right drill and avoiding damage. Many options exist, from simple online tools to advanced software and handy mobile apps. Each type offers unique benefits for different users and tasks.

Online Tools

Online drill torque calculators are easy to access through web browsers. They require no installation and work on any device. Users input drill size, material type, and speed to get torque values. These tools are great for quick checks and simple projects. They save time and provide instant results without complex steps.

Software Solutions

Software solutions offer detailed torque calculations for professionals. They include many settings like drill type, material hardness, and bit angle. These programs can handle complex projects and improve accuracy. Some software integrates with CAD systems for design support. They are ideal for engineers and technicians needing precise data.

Mobile Apps

Mobile apps bring drill torque calculators to your smartphone or tablet. They allow quick calculations on job sites or in workshops. Apps often include extra features like unit converters and material databases. Users can save results and share them easily. These apps provide convenience and flexibility for users on the move.

Tips For Maximizing Drill Torque Accuracy

Maximizing drill torque accuracy helps improve drilling results. Accurate torque ensures better control and efficiency. It reduces wear on tools and avoids damage to materials. Follow simple tips to keep your drill torque readings reliable and precise.

Regular Calibration

Calibration keeps your drill torque measurements accurate. Over time, tools lose their precision. Calibrate your drill and torque calculator regularly. Use standard weights or calibration devices for best results. This prevents errors and maintains consistency in your work.

Consistent Monitoring

Check torque readings often during use. Keep an eye on changes or drops in torque values. Monitoring helps spot problems early, like tool wear or battery issues. Note any unusual readings and address them quickly. This practice keeps your drill working at its best.

Using Quality Drill Bits

High-quality drill bits maintain torque accuracy better. Cheap bits wear out fast and change resistance. Use sharp, durable bits designed for your drill type. Replace bits when they become dull or damaged. Good bits reduce strain and give you better torque control.

Frequently Asked Questions

What Is A Drill Torque Calculator Used For?

A drill torque calculator estimates the torque needed for drilling tasks. It helps select the right drill and prevents tool damage. This tool saves time by providing accurate torque values for various materials and drill sizes.

How Do I Calculate Drill Torque Manually?

To calculate drill torque manually, multiply force by drill radius. Torque equals force times distance from the pivot point. This method requires knowing the applied force and drill bit length.

Why Is Torque Important In Drilling?

Torque ensures efficient drilling without damaging materials or tools. Proper torque prevents drill bit slipping and overheating. It improves drilling accuracy and prolongs equipment life.

Can A Drill Torque Calculator Improve Drilling Safety?

Yes, it helps avoid over-torquing, reducing tool breakage risk. Correct torque settings prevent accidents and equipment failure. It promotes safer and more efficient drilling operations.

Conclusion

Using a drill torque calculator saves time and effort. It helps find the right torque quickly and easily. This tool ensures you do not damage screws or tools. Accurate torque improves the quality of your work. It also helps protect your drill from wear.

Simple to use, it suits both beginners and experts. Try the calculator for better drilling results today. Your projects will become smoother and more precise. Keep your tools safe and your work strong.