Have you ever wondered how a drill press works and why it’s a must-have tool in any workshop? If you want to make precise holes quickly and with less effort, understanding your drill press is key.

This powerful machine can save you time and improve your projects, but only if you know how to use it right. Keep reading, and you’ll discover exactly how a drill press works, so you can get the most out of your tool and take your skills to the next level.

Credit: makerspaces.northeastern.edu

Drill Press Basics

A drill press is a powerful tool used to drill precise holes in various materials. It holds the drill bit steady while applying pressure to the workpiece. This makes drilling easier and more accurate than using a handheld drill. Understanding the basics helps you use the drill press safely and effectively.

Key Components

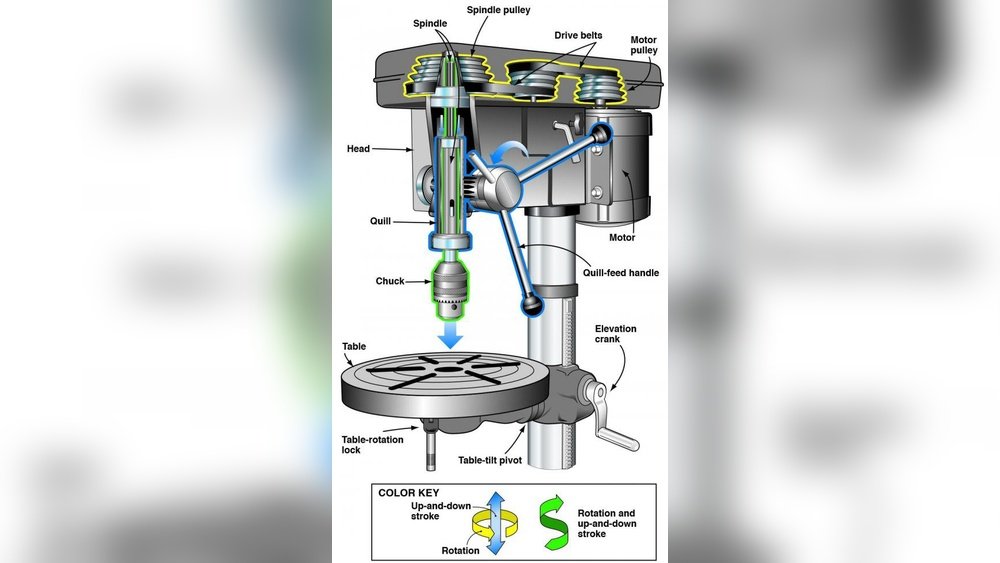

The drill press has several main parts. The base supports the entire machine and keeps it stable. The column is a vertical pole that holds the head and the table. The table holds the material you are drilling and can move up or down. The head contains the motor and the spindle, which spins the drill bit. The feed handles lower the drill bit into the material. Each part works together for precise drilling.

Types Of Drill Presses

There are different types of drill presses for different needs. A bench drill press is small and fits on a workbench. It is good for light tasks and small projects. A floor drill press is larger and stands on the floor. It has more power and can handle bigger jobs. Radial drill presses have an arm that moves the drill head over the workpiece. This type is useful for large or heavy materials.

How Drill Presses Operate

Understanding how drill presses operate helps users work safely and effectively. A drill press uses mechanical parts to drill holes precisely in wood, metal, or plastic. Each part plays a role in controlling speed, power, and accuracy.

Power Transmission

The drill press gets power from an electric motor. The motor spins a belt or gears that transfer energy to the spindle. This system changes the motor’s speed and torque to match the drilling task. Power transmission ensures steady and controlled drilling action.

Spindle And Chuck Mechanism

The spindle holds and turns the drill bit. It moves up and down to drill into the material. At the spindle’s end is the chuck, which grips the drill bit tightly. The chuck can open or close to change bits quickly and securely.

Speed Control

Speed control adjusts how fast the drill bit spins. Drill presses use pulleys, belts, or electronic controls for this. Lower speeds work best for metal or hard materials. Higher speeds suit wood or soft materials. Proper speed helps make clean and precise holes.

Setting Up For Precision

Setting up your drill press correctly is key to making precise holes. Small mistakes can cause big problems in your work. Take time to prepare carefully. This helps you drill clean and accurate holes every time.

Follow simple steps before you start. This saves time and material. Precision comes from good alignment, the right tools, and proper settings.

Aligning The Workpiece

Place your workpiece firmly on the drill press table. Use clamps or a vise to hold it steady. Check that the hole mark is under the drill bit tip. Adjust the table or the piece to line up exactly. This prevents the drill from slipping or making off-center holes.

Choosing The Right Drill Bit

Select a drill bit that fits the material and hole size. Use bits made for wood, metal, or plastic as needed. Sharp bits cut cleaner and need less force. Replace dull or bent bits to avoid poor results and damage.

Adjusting Depth And Speed

Set the drill press depth stop to control hole depth. This keeps holes uniform and avoids drilling too deep. Adjust the speed based on material hardness. Slower speeds suit metal, while faster speeds work for wood. Correct speed reduces heat and bit wear.

Techniques For Accurate Drilling

Accurate drilling is crucial for any project using a drill press. Proper techniques help avoid mistakes and ensure clean, precise holes. Careful preparation and steady handling improve the final result. Below are some key methods to drill with accuracy and confidence.

Marking And Centering

Start by marking the exact spot for the hole. Use a pencil or marker with a fine tip. A center punch helps create a small dent on the mark. This dent guides the drill bit and stops it from slipping. Align the drill bit with the dent before starting.

Using Clamps And Jigs

Secure the workpiece firmly to the drill press table. Clamps prevent movement during drilling. Jigs hold the piece in the correct position. They also help drill multiple holes at the same distance. Using clamps and jigs improves safety and accuracy.

Maintaining Consistent Pressure

Apply steady, even pressure on the drill press handle. Avoid pushing too hard, which can damage the bit or material. Too little pressure can cause the bit to wander. Let the drill bit do the cutting. Keep the speed steady for smooth holes.

Safety Tips

Using a drill press can be safe if you follow some important rules. Safety helps you avoid injuries and work better. Always stay alert and respect the machine.

Protective Gear

Wear safety glasses to protect your eyes from flying bits. Use ear protection to guard against loud noise. Gloves can protect your hands, but avoid loose ones that may catch in the drill. Wear a dust mask if you drill materials that create dust.

Avoiding Common Hazards

Never wear loose clothing or jewelry near the drill press. Tie back long hair to keep it away from moving parts. Keep your hands clear of the spinning drill bit. Use clamps to hold your workpiece instead of your hands. Always check the speed setting before starting the machine.

Proper Machine Maintenance

Clean the drill press after each use to remove debris. Check belts and pulleys for wear and replace if needed. Lubricate moving parts regularly to keep the machine smooth. Tighten all bolts and screws to prevent loose parts. Inspect the drill bit for damage and replace it if dull or broken.

Credit: wenproducts.com

Troubleshooting Common Issues

Troubleshooting common drill press issues helps keep your work smooth. Problems can slow down projects and cause frustration. Knowing how to fix these issues saves time and effort. This section covers three frequent problems and their solutions.

Drill Bit Slipping

Drill bit slipping occurs when the bit spins inside the chuck. This reduces control and can damage the workpiece. Tighten the chuck firmly to hold the bit in place. Clean the chuck and bit shank to remove dust and oil. Replace worn or damaged chucks for better grip. Use the correct size bit for your chuck.

Inconsistent Hole Depth

Inconsistent hole depth means holes are not drilled to the same depth. Check if the depth stop is set correctly and securely. Adjust the depth stop to the desired measurement before drilling. Make sure the workpiece is flat and stable on the table. Avoid lifting the drill during the process to keep depth steady.

Machine Vibrations

Machine vibrations affect precision and cause discomfort. Tighten all bolts and screws on the drill press. Ensure the drill press is on a solid, level surface. Check the belt for wear or looseness and replace if needed. Balance the drill bit by using sharp, undamaged bits. Regular maintenance reduces vibrations over time.

Advanced Features And Accessories

Advanced features and accessories improve drill press performance and ease of use. They help users work with more accuracy and safety. These additions turn a basic drill press into a versatile tool. Each feature has a specific role in making drilling tasks smoother and faster.

Laser Guides

Laser guides show the exact spot where the drill bit will hit. This feature helps align the workpiece without guesswork. Users can position materials quickly and avoid mistakes. The laser line improves accuracy for precise drilling every time.

Digital Depth Gauges

Digital depth gauges measure how deep the drill bit goes. They display the depth on a clear digital screen. This feature helps drill holes at the exact depth needed. It prevents drilling too deep or too shallow. Users can set and repeat hole depths easily.

Specialized Clamping Systems

Specialized clamping systems hold workpieces firmly in place. They reduce movement during drilling and increase safety. Different clamps fit various shapes and sizes of materials. These systems help users maintain control and ensure clean holes.

Credit: www.drill-straight-tools.com

Frequently Asked Questions

How Does A Drill Press Operate?

A drill press uses a motor to rotate a drill bit vertically. It allows precise drilling by lowering the bit into the material with a lever. The machine offers stability and accuracy compared to handheld drills.

What Are The Main Parts Of A Drill Press?

Key parts include the base, column, table, spindle, and motor. The base supports the machine, the column holds the spindle, and the table holds the workpiece. The motor powers the spindle to rotate the drill bit.

Can Drill Presses Drill Different Materials?

Yes, drill presses can handle wood, metal, plastic, and more. You just need the appropriate drill bit and correct speed settings for each material to ensure clean, safe drilling.

Why Use A Drill Press Instead Of A Handheld Drill?

A drill press provides better precision, stability, and control. It keeps the drill bit steady, ensuring straight holes. It’s ideal for repetitive or accurate drilling tasks.

Conclusion

A drill press helps you make precise holes quickly and safely. It uses a motor to turn the drill bit at steady speeds. You can adjust the depth and angle to fit your project. This tool works well for wood, metal, and plastic materials.

Understanding how it operates can improve your work quality. Try using a drill press for accurate and clean drilling every time.