Have you ever wondered what makes your cordless drill buzz to life the moment you press the trigger? Understanding how a cordless drill works, especially through its schematics, can give you a new level of confidence every time you pick it up.

Whether you want to fix it yourself, improve your DIY skills, or simply satisfy your curiosity, knowing the inner workings can make a big difference. You’ll discover the key parts inside your cordless drill and how they work together to deliver power right at your fingertips.

Keep reading, and you’ll see your drill in a whole new light.

Cordless Drill Basics

A cordless drill is a handy tool used for drilling holes and driving screws. It works without a power cord, giving freedom to move around. The design is simple but clever, combining several parts to work together. Understanding these basics helps you see how the drill functions and what makes it effective.

The drill uses electricity from a battery to power a motor. The motor turns a chuck that holds drill bits or screwdriver heads. This motion makes drilling or screwing possible. Let’s look closer at the main parts and how they work.

Main Components

The main components include the battery, motor, chuck, trigger, and gearbox. The battery stores power and sends it to the motor. The motor creates motion. The chuck holds the drill bit or driver. The trigger controls the motor speed. The gearbox adjusts torque and speed for different tasks.

Power Source

The power source of a cordless drill is a rechargeable battery. Most use lithium-ion batteries. These batteries are light and hold charge longer. They supply the electric current needed for the motor. Battery capacity affects how long the drill runs before recharging.

Motor Function

The motor converts electrical energy into mechanical energy. When the trigger is pressed, current flows to the motor. The motor spins the drill shaft. Speed and power depend on the motor’s design and battery voltage. The motor’s rotation drives the chuck to turn the drill bit.

Credit: kids.frontiersin.org

Battery And Charging

The battery and charging system are key to a cordless drill’s performance. They provide the power needed for the drill to work without a cord. Understanding the types of batteries, how charging works, and how to care for the battery helps you get the best use from your tool.

Types Of Batteries

Cordless drills mostly use three types of batteries: Nickel-Cadmium (NiCd), Nickel-Metal Hydride (NiMH), and Lithium-Ion (Li-Ion). NiCd batteries are older and heavier but cost less. NiMH batteries hold more charge and are lighter than NiCd. Li-Ion batteries are the most common today. They are light, hold charge longer, and charge faster. Choosing the right battery affects drill runtime and power.

Charging Mechanism

The charging process uses a charger that fits the battery type. The charger sends electricity to the battery to fill its cells with energy. Smart chargers stop charging when the battery is full to avoid damage. Some chargers show a light to indicate charging status. Quick chargers can fill batteries in 30 minutes. Proper charging ensures the drill is ready to use anytime.

Battery Maintenance Tips

Keep batteries cool and dry to extend their life. Avoid leaving batteries fully drained for a long time. Charge the battery before storing it for a long period. Remove the battery from the drill if not in use. Clean battery contacts regularly to keep good connection. Follow these simple steps to keep your drill working well.

Internal Wiring And Schematics

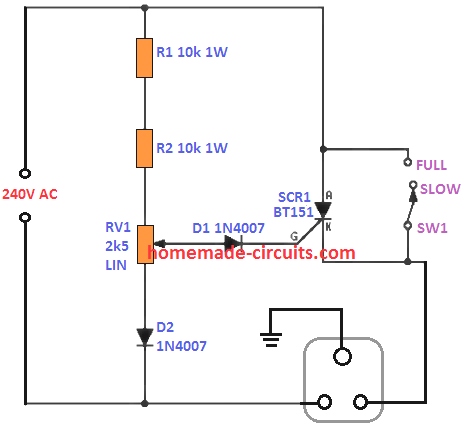

The internal wiring and schematics of a cordless drill form the backbone of its operation. These parts direct electrical power from the battery to the motor and control systems. Understanding this layout helps in grasping how the drill works efficiently and safely.

Inside the drill, wires connect the battery, motor, switches, and other components. The schematic shows how these parts link together. Each wire carries electric current along a specific path. This flow powers the motor and controls speed and torque.

Circuit Layout

The circuit layout shows the path of electricity inside the drill. It includes the battery, motor, and control board. Wires connect these parts to complete the circuit. The layout ensures power flows smoothly and reaches the motor without loss.

Most cordless drills use a simple circuit with a few key parts. A rechargeable battery supplies electric power. The motor converts electrical energy into motion. A control board manages the speed and torque.

Switch And Trigger System

The switch and trigger system controls the drill’s operation. Pressing the trigger closes the circuit, allowing current to flow. This action powers the motor and starts the drill bit spinning.

The trigger also controls speed. The harder you press, the more current flows. This increases the motor speed and torque. The wiring connects the trigger to the battery and motor, completing the circuit.

Safety Features

Safety features protect users and the drill’s internal parts. Many drills include a fuse or circuit breaker. This stops current flow if there is an overload or short circuit.

Some drills have thermal sensors. These cut power if the motor gets too hot. Wiring connects these safety parts into the main circuit. This prevents damage and keeps the drill safe to use.

Gear And Transmission

The gear and transmission system plays a key role in a cordless drill. It changes the motor’s power into usable force to turn the drill bit. This system controls how fast and how strong the drill spins. Understanding these parts helps you see how the drill works efficiently.

Gear Types

There are usually two main gear types inside a cordless drill. Spur gears are common and have straight teeth. They provide a smooth transfer of power. Another type is planetary gears. They are compact and allow for different speed options. Both gear types help adjust the drill’s speed and torque.

Speed Control

The transmission controls the drill’s speed by changing gear ratios. Lower gears give more power but slower speed. Higher gears provide faster rotation but less force. This balance helps with different tasks, like drilling or driving screws. The user can switch gears to match the job.

Torque Adjustment

Torque is the twisting force that turns the drill bit. The gear system adjusts torque by changing how much power reaches the bit. More torque means the drill can handle tougher materials. Less torque helps avoid damaging softer materials. This adjustment is crucial for precise work.

Motor Operation

The motor is the heart of a cordless drill. It converts electrical energy into mechanical motion. This motion spins the drill bit, allowing it to bore holes or drive screws. Understanding how the motor works helps explain the drill’s power and efficiency.

Inside the motor, magnets and coils interact. Electric current flows through the coils, creating a magnetic field. This field pushes and pulls the motor’s rotor, making it turn. The design of the motor affects speed, torque, and battery life.

Brushless Vs Brushed Motors

Brushed motors use physical brushes to transfer electricity to the rotor. These brushes wear out over time and create friction. Brushless motors use electronic controllers instead of brushes. They last longer and need less maintenance. Brushless motors also run quieter and produce more power in a smaller size.

Motor Efficiency

Efficiency means how well the motor turns electricity into motion. Brushless motors are more efficient than brushed ones. They waste less energy as heat. Higher efficiency means longer battery life and better performance. Efficient motors allow the drill to work harder for longer periods.

Heat Management

Motors generate heat during operation. Too much heat can damage the motor and battery. Cordless drills have designs to manage heat. Ventilation holes and cooling fins help air flow. Some drills include thermal sensors to prevent overheating. Good heat management keeps the drill safe and extends its life.

Troubleshooting Common Issues

Troubleshooting common issues with a cordless drill helps keep it working well. Many problems are easy to fix and save time and money. Understanding basic faults lets you spot problems fast. This guide covers common issues and how to solve them.

Power Failures

Power failures often come from battery issues. Check if the battery is fully charged. Dirty or loose battery contacts can stop power flow. Clean contacts with a dry cloth for better connection. Sometimes, the battery might be old and need replacement. Also, inspect the charger to ensure it works correctly. Faulty chargers cannot recharge batteries properly.

Overheating

Overheating happens when the drill runs too long or under heavy load. Let the drill rest to cool down if it feels hot. Blocked air vents reduce cooling and cause heat buildup. Keep vents clean and clear of dust. Overheating can damage internal parts if ignored. Use the drill at a steady pace to prevent overheating. Avoid pressing too hard on the drill during use.

Mechanical Problems

Mechanical problems include unusual noises or difficulty turning the drill bit. Loose parts inside the drill cause these issues. Tighten any visible screws or bolts carefully. Worn-out gears or brushes inside need professional repair or replacement. Check the chuck for damage or dirt that can stop bits from holding tightly. Lubricate moving parts to ensure smooth operation. Regular maintenance prevents many mechanical faults.

Advancements In Cordless Drill Technology

Cordless drill technology has improved a lot over the years. These tools have become smarter, stronger, and easier to use. New designs and features help users work faster and safer. Advances in batteries, electronics, and shape make a big difference. The latest cordless drills offer more than just power. They include smart controls and comfort features. These improvements help both beginners and experts.

Smart Features

Modern cordless drills have smart controls for better precision. Some models use sensors to adjust speed automatically. This helps avoid stripping screws or damaging materials. Built-in LED lights brighten dark work areas. Digital displays show battery life and torque settings. Bluetooth connectivity lets users customize settings through apps. These features make drilling easier and more accurate.

Improved Battery Life

Battery technology has advanced with longer run times and faster charging. Lithium-ion batteries are common due to their light weight and power. New batteries hold more charge and last longer between uses. Some drills have removable batteries for quick swaps. Efficient motors use less power, extending battery life. This means users spend less time charging and more time working.

Ergonomic Design

Ergonomics focus on comfort and control during use. Modern drills have lighter bodies and better balance. Soft grips reduce hand fatigue during long projects. Compact designs allow use in tight spaces. Some drills have adjustable handles for different angles. These design changes help users work comfortably and safely.

Credit: www.homemade-circuits.com

Credit: electronics.stackexchange.com

Frequently Asked Questions

How Does A Cordless Drill Generate Power?

A cordless drill uses a rechargeable battery to supply electrical energy. This powers the motor, which turns the drill bit. The battery’s voltage and capacity determine the drill’s power and runtime. This design allows for portability and convenience without needing a constant power source.

What Are The Main Components Of Cordless Drill Schematics?

Cordless drill schematics include the battery, motor, trigger switch, gearbox, and circuit board. The battery provides power, the motor drives the drill bit, and the switch controls operation. The gearbox adjusts speed and torque, while the circuit board manages electrical flow and safety.

How Does The Trigger Control The Drill’s Speed?

The trigger is a variable switch that adjusts the electrical current to the motor. Pressing it lightly delivers low power for slow speed. Pressing it fully allows maximum current, increasing speed. This mechanism offers precise control during drilling tasks.

Why Is A Gearbox Important In Cordless Drills?

The gearbox converts high-speed motor rotation into lower-speed, high-torque output. This helps the drill handle tough materials without stalling. It provides multiple speed settings and optimizes power for different drilling or driving tasks, increasing efficiency and control.

Conclusion

Understanding a cordless drill’s schematics helps you use it better. The battery powers the motor, which turns the drill bit. Wires and switches connect parts to control speed and torque. Knowing these basics makes repairs easier and boosts your confidence.

Next time you work with a drill, remember how its parts fit together. Simple ideas, clear functions. That’s how a cordless drill works.