Have you ever wondered how a drill press actually moves down when you’re working on a project? Understanding this simple but powerful action can make a big difference in how you use your drill press safely and effectively.

Whether you’re a beginner or just want to get better results, knowing exactly how the drill press goes down gives you more control over your work. Keep reading, and you’ll discover the key parts and steps that make this happen—so you can drill with confidence every time.

Credit: www.protoolreviews.com

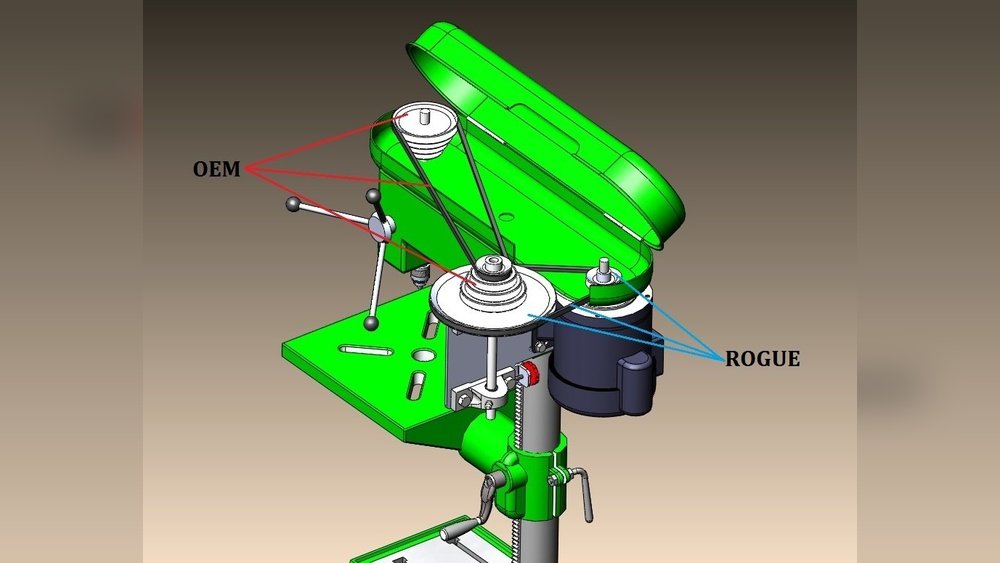

Drill Press Basics

A drill press is a tool used to make holes in different materials. It holds a drill bit and moves it down to cut into the material. This tool provides precision and control, making it easier to drill straight holes.

Understanding the basics helps you use a drill press safely and effectively. Knowing its parts and types will give you a clear idea of how it works and what fits your needs.

Main Components

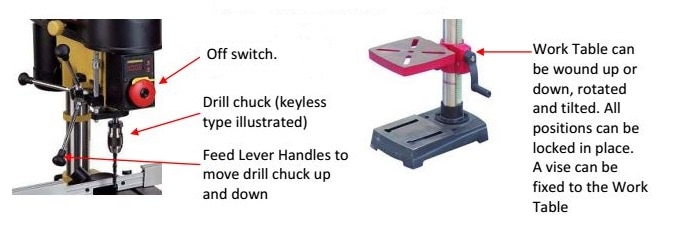

A drill press has several key parts. The base supports the whole machine and keeps it steady. The column is a strong, vertical post that holds the head and table in place.

The table is where you place your workpiece. It can move up, down, and rotate to fit the drilling angle. The head contains the motor and the spindle that holds the drill bit.

The spindle moves the drill bit down into the material. This movement happens when you pull the feed handles. These handles give you control over how deep the bit goes.

Types Of Drill Presses

There are several types of drill presses. A bench drill press is small and fits on a workbench. It works well for light jobs and small spaces.

A floor drill press is bigger and stands on the floor. It has more power and can handle larger workpieces. It suits heavy-duty tasks and workshops.

Radial drill presses have an arm that moves the drill head horizontally. This allows drilling in large or awkward pieces. It offers more flexibility and reach than other types.

Spindle Movement

The spindle movement is key to how a drill press works. It controls the drill bit’s motion down into the material. This movement must be smooth and precise. It helps make clean and accurate holes. The spindle moves vertically, guided by the machine’s design.

Role Of The Spindle

The spindle holds the drill bit firmly. It spins the bit at different speeds. This spinning cuts into the workpiece. The spindle also moves down to drill the hole. It controls how deep the drill bit goes. The user adjusts the spindle’s position for the right depth.

Vertical Travel Mechanism

The spindle moves down using a vertical travel mechanism. This system guides the spindle in a straight line. It usually includes a rack and pinion or a lever. The operator pushes a handle or wheel to move the spindle down. This action lowers the drill bit toward the workpiece. Springs or counterweights help return the spindle back up after drilling.

Feed Handle Function

The feed handle is a key part of a drill press. It controls how the drill bit moves down into the material. This handle lets you apply steady pressure. It helps make clean, precise holes. Understanding its function helps you use the drill press safely and effectively.

How The Feed Handle Works

The feed handle connects to the drill press spindle. Turning the handle moves the spindle and drill bit down. It uses a simple lever system to control speed and force. You can move the handle smoothly or with more pressure. This lets you control the drill bit’s movement carefully.

Controlling Downward Motion

The feed handle controls the drill bit’s downward motion precisely. Push the handle down to lower the bit into the workpiece. Pull it up to raise the bit back out. This control helps prevent mistakes like drilling too deep. It also protects the drill bit from breaking.

Credit: extremehowto.com

Quill And Chuck Interaction

The quill and chuck work closely in a drill press. Their interaction controls how the drill bit moves down into the material. Understanding this connection helps in using the drill press correctly and safely.

Quill Mechanics

The quill is a hollow cylinder inside the drill press head. It holds the chuck and drill bit. When you pull the handle, the quill moves down smoothly. This movement guides the drill bit straight into the workpiece. Springs inside the quill help it return to the starting position. The quill’s design keeps the drill bit steady and precise.

Chuck Rotation And Stability

The chuck grips the drill bit tightly. It rotates with the motor spindle at high speed. The chuck must stay stable during rotation. This stability prevents wobbling and uneven holes. Tightening the chuck jaws ensures the bit does not slip. The combined action of the quill and chuck makes drilling accurate and safe.

Spring And Return Mechanism

The spring and return mechanism plays a key role in how a drill press moves up after drilling. This system uses a spring to pull the drill bit back to its starting position. It helps keep control and safety during work. Without this mechanism, the drill press would stay down, making it hard to use.

The mechanism also helps maintain the drill press’s smooth and steady operation. It avoids sudden movements that could damage the material or tool. Understanding this part helps users operate the drill press better and prevents problems.

Purpose Of The Return Spring

The return spring pulls the drill bit upward after pressing down. It stores energy while you push the drill down. Once you stop pressing, the spring releases this energy. This action lifts the drill bit back to its original place. It stops the bit from staying stuck in the material.

This spring also helps keep hands safe. It stops the drill from dropping quickly or falling unexpectedly. The return spring ensures the drill press is ready for the next use fast.

Ensuring Smooth Upward Movement

The spring works with other parts like the quill and lever to move the drill up smoothly. It controls the speed of the upward movement. This control prevents jerks and sudden snaps that can harm the machine.

Good maintenance of the spring and related parts keeps the movement smooth. Cleaning and lubricating these parts reduce friction. It makes the drill press last longer and work better.

Depth Stop Adjustment

The depth stop adjustment controls how far the drill bit moves down. It helps set the exact drilling depth. This feature is important for drilling holes with precision. It prevents drilling too deep or too shallow. Adjusting the depth stop is simple and quick.

Setting Drill Depth

First, loosen the depth stop lock. Move the stop rod to the desired depth. Use a ruler or depth gauge for accuracy. Tighten the lock to hold the stop in place. The drill will stop moving down at this point.

Safety And Precision

The depth stop keeps the drill bit from going too far. This protects the workpiece and drill bit from damage. It also reduces the risk of injury. Using the depth stop ensures clean and consistent holes. Always check the stop before starting your drill press.

Common Issues And Maintenance

Understanding common issues and maintenance helps keep your drill press working well. Problems with the downward movement can stop your work. Regular checks prevent bigger troubles. Simple care extends your drill press life.

Troubleshooting Downward Movement

Sometimes the drill press does not go down smoothly. The handle might feel stiff or stuck. This can happen if dirt or rust blocks the parts. Check the quill and spindle for any dirt. Clean these parts with a soft cloth. Make sure the locking lever is not tight. Loosen it if needed. If the drill press still won’t go down, check the feed springs. Broken springs can stop the downward motion. Replace any damaged springs quickly to fix the issue.

Lubrication And Wear

Lubrication keeps the drill press parts moving easily. Use machine oil on moving parts like the quill and spindle. Avoid over-oiling; a small amount is enough. Too much oil can attract dirt. Check the feed rack and pinion gears often. Worn gears cause rough movement or slipping. Replace worn parts to maintain smooth operation. Regular oiling and part checks reduce wear and tear. This keeps your drill press running safely and smoothly.

Credit: oferguson.weebly.com

Frequently Asked Questions

How Does A Drill Press Lower The Drill Bit?

A drill press lowers the drill bit using a lever or handle connected to a rack and pinion or a quill mechanism. Turning the handle moves the drill bit down vertically for precise drilling. This controlled movement ensures accuracy and safety during operation.

What Controls The Downward Movement Of A Drill Press?

The downward movement is controlled by a spindle quill operated via a feed lever. The quill slides vertically within the head, allowing smooth and controlled lowering of the drill bit onto the workpiece.

Why Is Controlled Descent Important In A Drill Press?

Controlled descent prevents drill bit damage and ensures precision. It allows gradual pressure, reducing heat and bit wear. It also improves safety by avoiding sudden drops that could harm the operator or workpiece.

Can The Drill Press Speed Affect How It Goes Down?

Yes, drill press speed affects descent ease. Higher speeds may require slower feed to avoid overheating. Proper speed combined with controlled lowering ensures clean, accurate holes without damaging the material or bit.

Conclusion

A drill press moves down by turning a handle or lever. This action lowers the drill bit toward the workpiece. The spindle holds the bit firmly as it moves. The user controls the speed and pressure carefully. This helps create clean, accurate holes every time.

Understanding this simple process makes using a drill press easier. Practice helps you gain confidence and skill quickly. Keep safety in mind and work slowly. Soon, drilling will feel natural and precise.