Have you ever struggled to keep your workpiece steady while drilling? A drill press vice could be the simple tool that changes everything for you.

But how does a drill press vice work, and why is it so important for your projects? Understanding this can save you time, improve your accuracy, and make your work much safer. Keep reading, and you’ll discover exactly how this handy device holds your materials firmly in place, giving you the confidence to tackle even the toughest drilling tasks with ease.

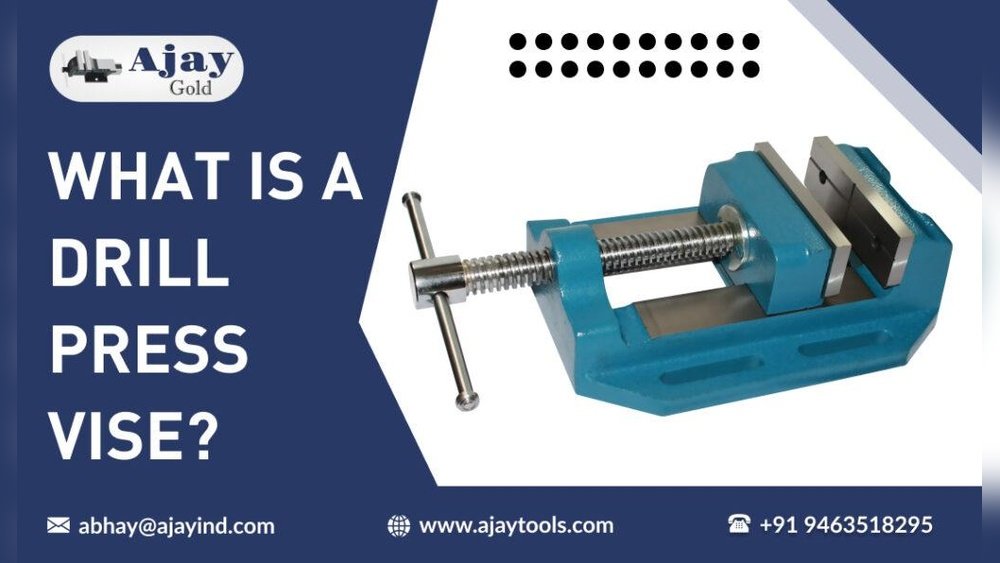

Basics Of A Drill Press Vice

A drill press vice is a tool used to hold objects tightly in place during drilling. It keeps the workpiece steady and safe. This helps make accurate holes without slipping or movement.

Understanding the basics of a drill press vice makes it easier to choose and use the right one. It has parts that work together to grip materials firmly. Different types of vices fit different tasks and materials.

Core Components

A drill press vice has several key parts. The base sits flat on the drill press table. It supports the entire vice.

The fixed jaw stays in place and holds one side of the workpiece. The movable jaw slides to clamp the object. You tighten it using a screw mechanism.

The handle turns the screw to move the jaw. This action tightens or loosens the grip on the material. Some vices have a swivel base to adjust the angle.

Types Of Drill Press Vices

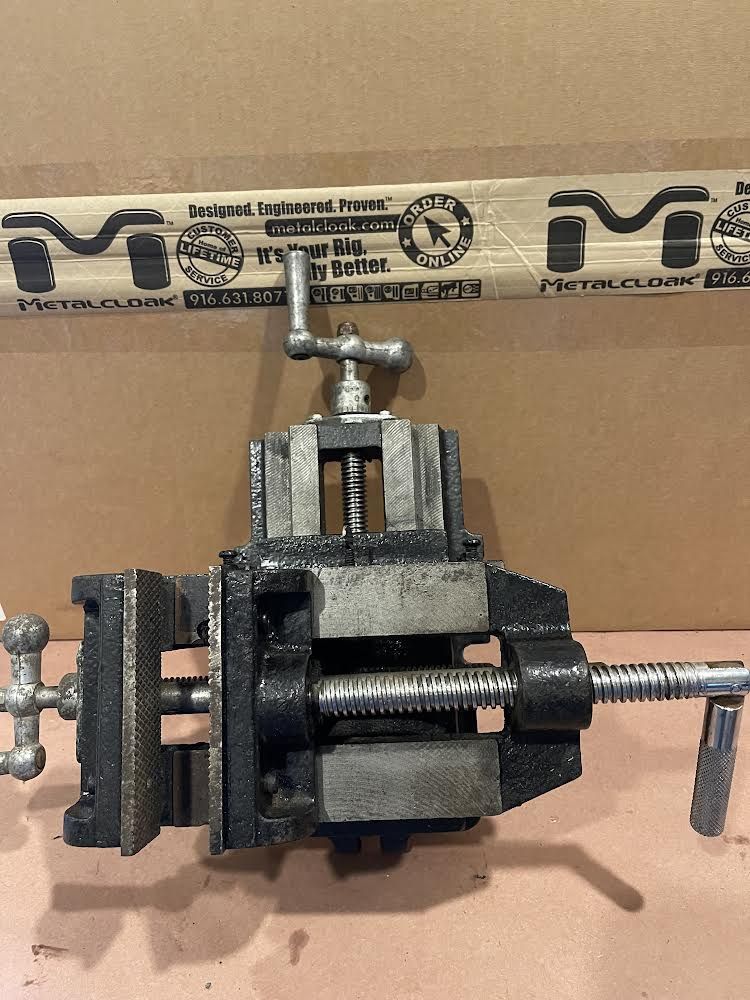

There are several types of drill press vices. A standard drill press vice is simple and strong. It holds flat or small objects well.

A swivel drill press vice rotates to allow angled drilling. This helps when you need to drill at a specific angle. Some vices come with quick-release features for fast adjustments.

Specialty vices include tilting or clamp-style models. They provide extra support for unusual shapes or sizes. Choosing the right type depends on your project needs.

Credit: abmf.org

Setup And Installation

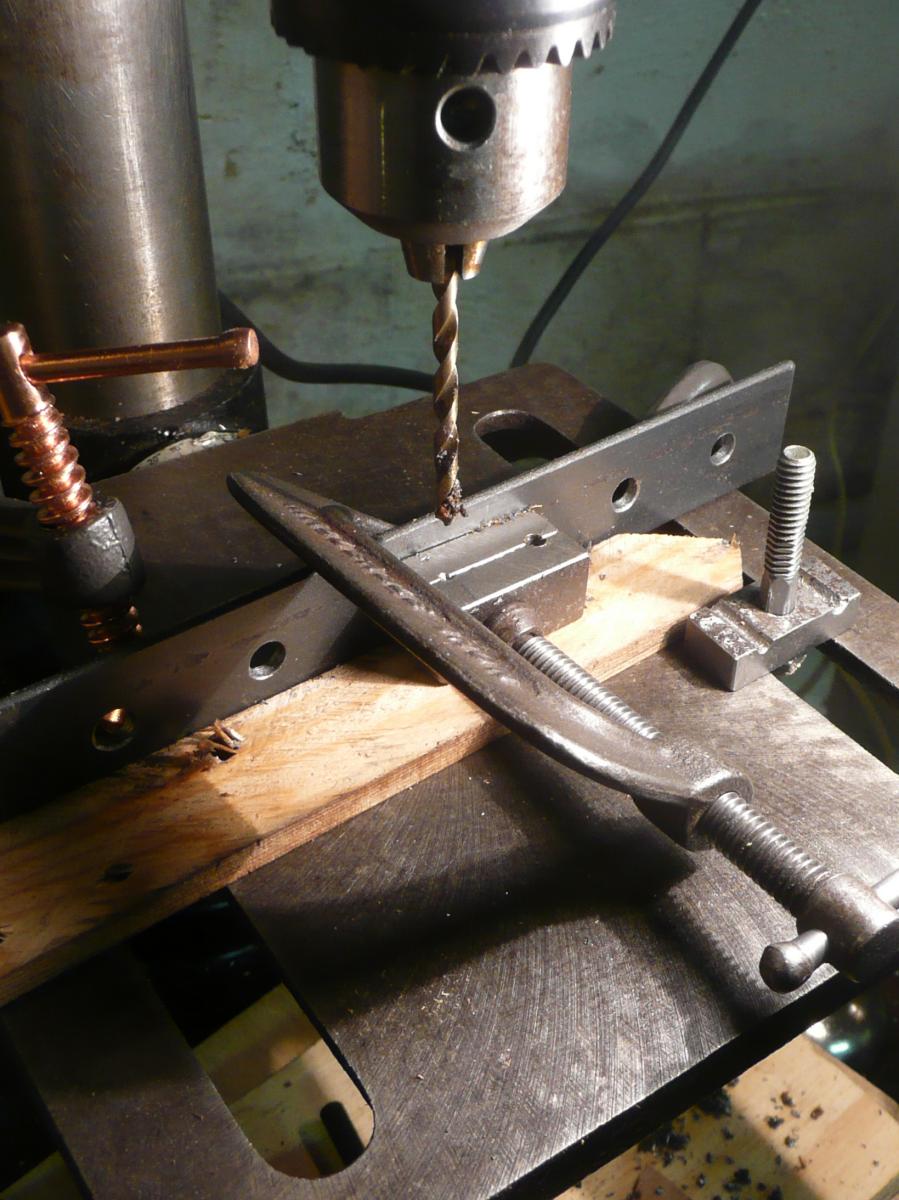

Setting up a drill press vice correctly is key for safe and precise work. Proper installation ensures the vice holds materials firmly. It also helps avoid mistakes during drilling. Follow simple steps to mount and align the vice perfectly.

Mounting The Vice

Place the vice on the drill press table. Use bolts or clamps to fix it tightly. Check that the vice does not move when tightened. Tighten the bolts evenly on both sides. This prevents the vice from tilting or shifting during use. Make sure the mounting bolts fit the table holes exactly.

Aligning For Accuracy

Align the vice jaws parallel to the drill bit. This keeps holes straight and accurate. Use a square or ruler to check alignment. Adjust the vice position until it lines up perfectly. Tighten all bolts again after alignment. Double-check the setup before starting your work. Proper alignment reduces errors and improves safety.

Operating Principles

The operating principles of a drill press vice are simple yet effective. This tool holds materials steady during drilling. It ensures accuracy and safety by preventing movement. Understanding how it works helps users get better results.

Clamping Mechanism

The clamping mechanism is the heart of the drill press vice. It consists of two jaws: one fixed and one movable. The movable jaw slides toward the fixed jaw to hold the workpiece. A screw or lever controls this movement. Tightening the screw moves the jaw closer, clamping the material firmly. This prevents slipping or shifting during drilling.

Adjusting Jaw Pressure

Jaw pressure controls how tightly the workpiece is held. Users adjust it by turning the screw or handle. Too little pressure allows the material to move. Too much pressure may damage the workpiece or vice. Proper pressure keeps the item secure without causing harm. This balance ensures smooth and accurate drilling.

Tips For Precision Clamping

Precision clamping is key for accurate drilling. A drill press vice holds your workpiece firmly. This prevents movement during drilling. Tight and stable clamping ensures clean, precise holes. Follow these tips for best results.

Choosing The Right Vice

Select a vice that fits your drill press size. The jaws should open wide enough for your workpieces. Look for strong, durable materials like cast iron or steel. A vice with smooth jaw surfaces prevents damage to materials. Consider a vice with adjustable jaws for different shapes and sizes. This flexibility improves clamping precision.

Securing Workpieces Safely

Place the workpiece fully inside the vice jaws. Align it with the drill bit for accurate drilling. Tighten the vice handle firmly but avoid over-tightening. Over-tightening can damage the workpiece or the vice. Use soft jaw covers to protect delicate materials. Double-check the workpiece stability before drilling. This step prevents accidents and improves accuracy.

Common Issues And Solutions

Using a drill press vice can bring challenges. Common issues often affect work quality and safety. Fixing these problems keeps the tool reliable and safe. Below are two frequent issues and their solutions.

Jaw Slippage

Jaw slippage happens when the vice cannot hold the workpiece tightly. This issue causes the piece to move during drilling. Clean the jaws and workpiece surface to remove oil or dirt. Tighten the vice handle firmly, but do not over-tighten. If slippage continues, check for worn or damaged jaws. Replace jaws if needed to restore grip strength.

Misalignment Problems

Misalignment leads to uneven drilling and poor results. Check if the vice base sits flat on the drill press table. Adjust the base or use shims to level the vice. Ensure jaws are parallel and square to the drill bit. Loosen, reposition, and retighten the vice to correct alignment. Regularly inspect the vice for wear that causes misalignment.

Credit: www.homedepot.com

Maintenance And Care

Proper maintenance and care keep a drill press vice working smoothly. Regular attention prevents rust and wear. It also extends the tool’s life and improves safety. Simple steps like cleaning and lubrication make a big difference. These tasks are easy to do and save money in the long run.

Cleaning Techniques

Start by removing all dust and metal shavings from the vice. Use a soft brush or cloth to wipe the surfaces. Avoid water, as it can cause rust. For stubborn dirt, use a mild solvent or degreaser. Clean the screw threads carefully to prevent buildup. After cleaning, dry the vice completely before use.

Lubrication Points

Lubricate the screw threads regularly for smooth movement. Apply light machine oil or grease to the moving parts. Focus on the lead screw, handle, and sliding jaws. Avoid over-lubricating, which can attract dirt. Wipe off excess oil to keep the vice clean. Lubrication reduces friction and prevents wear on metal surfaces.

Enhancing Drill Press Efficiency

A drill press vice holds materials steady during drilling. This stability helps make clean, accurate holes. It saves time by preventing slips and mistakes. Using the right vice and tools can speed up your work. Small changes can improve your drill press setup.

Improving efficiency means working faster and with better results. A good vice reduces the need to reposition workpieces. It also protects your materials from damage. Understanding how to use accessories and upgrades helps get the best from your drill press vice.

Using Accessories

Accessories can increase the vice’s grip and versatility. Soft jaws protect delicate materials from scratches. Stop blocks allow quick and repeatable positioning of workpieces. Clamps can hold irregular shapes firmly in place. These tools reduce setup time and improve accuracy.

Using the right accessory depends on the material and task. Simple additions can make drilling safer and easier. They help keep materials secure without extra effort.

Upgrading Vice Features

Upgrading your drill press vice improves performance and ease of use. A swivel base allows you to change angles quickly. Quick-release mechanisms speed up clamping and releasing. Hardened steel jaws last longer and provide stronger grip. Some vices include built-in measuring scales for precision.

Better vices reduce hand strain and improve control. Investing in these features saves time on each job. It also makes drilling more consistent and reliable.

Credit: homepage.cs.uiowa.edu

Frequently Asked Questions

What Is A Drill Press Vice Used For?

A drill press vice securely holds workpieces during drilling. It prevents movement, ensuring precise and safe drilling. It is essential for accurate holes and consistent results in metal or wood projects.

How Does A Drill Press Vice Improve Drilling Accuracy?

The vice clamps the material firmly, stopping any shift or wobble. This stability allows the drill to hit the exact spot every time. It reduces errors and improves overall precision in your work.

Can A Drill Press Vice Fit All Drill Presses?

Most drill press vices are adjustable and fit standard drill tables. However, sizes vary, so check compatibility with your drill press model. Proper fitting ensures safe and effective use.

How Do You Properly Secure A Workpiece In A Drill Press Vice?

Place the workpiece flat against the vice jaws. Tighten the screw handle firmly without over-tightening. Ensure the workpiece is stable and aligned with the drill bit before starting.

Conclusion

A drill press vice holds workpieces firmly during drilling. It keeps materials steady and safe. The vice’s jaws clamp tightly to avoid slipping. You adjust the vice with a handle or screw. This tool helps create accurate holes every time.

Using a drill press vice saves effort and improves results. Understanding how it works makes your projects easier. Try using one for better control and precision. Simple, strong, and effective—this tool supports your work well.