Are you wondering how much torque you really need in an impact driver? Choosing the right torque can make your work faster, easier, and more precise.

Too little power, and you’ll struggle with tough screws; too much, and you might damage your materials or tools. You’ll discover exactly what torque means for your projects and how to pick the perfect impact driver that matches your needs.

Keep reading to make smarter, more confident buying decisions that save you time and effort.

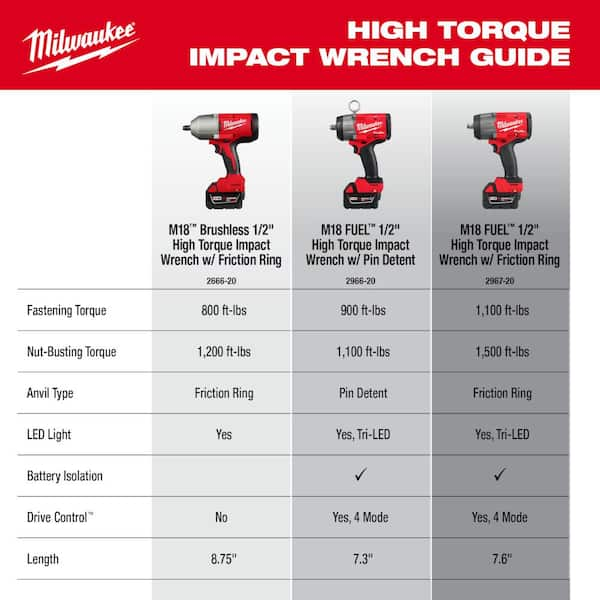

Credit: www.homedepot.com

Torque Basics

Understanding torque is key to choosing the right impact driver. Torque affects how well the tool turns screws and bolts. It shows the force the driver applies. Knowing torque basics helps you pick the best tool for your needs.

Different tasks need different torque levels. Too little torque means the driver won’t do the job. Too much torque can damage screws or materials. Let’s explore the main ideas about torque.

What Torque Means

Torque is a twisting force that makes things turn. It is measured in units like inch-pounds or Newton-meters. The higher the torque, the stronger the twisting force. Impact drivers use torque to spin bits fast and tight.

Think of torque as how hard the driver twists a screw. More torque helps with bigger screws and tougher materials. Less torque works for small screws or delicate work.

Torque Vs Power

Power and torque are not the same. Power is how fast a tool works. Torque is how strong it turns. A tool can have high power but low torque or vice versa.

Impact drivers need good torque to do tough jobs. Power helps the driver keep working without slowing down. Both matter, but torque is more important for driving screws.

Measuring Torque

Torque is measured with special tools called torque wrenches or meters. These tools show the twisting force in numbers. Impact driver boxes often list the maximum torque.

Knowing the torque number helps you choose the right driver. Higher torque means the driver can handle harder jobs. Check the torque rating before buying your impact driver.

Credit: www.reddit.com

Impact Driver Torque Range

Impact drivers come with different torque levels. Torque is the force that helps the tool turn screws and bolts. Choosing the right torque depends on the type of job. Understanding the torque range helps pick the best tool for each task.

Low Torque Models

Low torque impact drivers offer around 400 to 800 inch-pounds of torque. They work well for light tasks like assembling furniture or hanging pictures. These models are lighter and easier to control. Perfect for beginners or small home projects.

Mid Range Torque

Mid range impact drivers deliver between 800 and 1,200 inch-pounds of torque. They handle most household jobs with ease. Tasks like building decks or fixing fences fit this range well. Balanced power and control make them versatile for many users.

High Torque Options

High torque impact drivers provide 1,200 inch-pounds or more. These powerful tools tackle tough jobs like heavy construction and automotive work. They drive large screws and bolts quickly. Ideal for professionals or serious DIYers needing extra strength.

Matching Torque To Tasks

Choosing the right torque for your impact driver is key to working safely and efficiently. Different tasks need different power levels. Too little torque means the job won’t get done. Too much torque can damage materials or tools. Understanding how to match torque to your tasks helps you pick the right driver and avoid problems.

Light Duty Uses

Light duty tasks require less torque. These include driving small screws and assembling furniture. Usually, torque around 500 to 1,000 inch-pounds is enough. This prevents stripping screws or damaging soft wood. Light duty drivers are often compact and easy to handle. They work well for home projects and quick fixes.

Medium Duty Applications

Medium duty jobs need more power. Tasks like building decks or fixing fences fall here. Torque from 1,200 to 1,800 inch-pounds suits these uses. This level can drive larger screws and bolts into harder materials. Medium duty impact drivers balance power and control. They are ideal for regular DIY and repair work.

Heavy Duty Jobs

Heavy duty tasks demand high torque. Examples include construction work and automotive repairs. Torque above 2,000 inch-pounds helps handle thick bolts and tough materials. These drivers are larger and more robust. Heavy duty impact drivers deliver strong force without losing precision. They suit professionals and serious DIYers.

Factors Influencing Torque Needs

Torque is the twisting force an impact driver applies to fasten or loosen screws and bolts. The amount of torque you need depends on several key factors. These factors help determine the power required for your tasks. Understanding them ensures you choose the right tool for your work.

Material Type

Different materials need different torque levels. Soft materials like plastic or softwood need less torque to avoid damage. Hard materials like metal or hardwood require more torque to drive fasteners securely. Knowing the material type helps prevent stripping or breaking.

Fastener Size And Type

Large screws and bolts need more torque to tighten properly. Small fasteners require less force to avoid snapping. The type of fastener also matters. For example, lag bolts need higher torque than drywall screws. Match torque to fastener size and type for best results.

Work Environment

Work conditions affect torque needs too. Tight spaces may limit tool size and torque. Outdoor jobs might require more torque to handle dirt or rusted fasteners. Cold weather can make materials harder, increasing torque needs. Consider the environment before choosing torque power.

Choosing The Right Impact Driver

Choosing the right impact driver is important for your projects. The right tool makes work faster and easier. You need to think about power, comfort, and extra features. Each factor helps you pick the best driver for your needs.

Understanding these points helps you avoid buying a tool that is too weak or too heavy. A good impact driver fits your tasks and feels good in your hand.

Battery Vs Corded Options

Battery-powered impact drivers give freedom to move anywhere. No cords limit your reach. They work well for quick jobs and outdoor tasks. Corded drivers plug into power outlets. They offer steady, strong power without stopping. Corded models suit long tasks where constant power is needed. Choose battery for portability and corded for continuous use.

Ergonomics And Weight

Comfort matters when using impact drivers for a long time. Light tools reduce arm tiredness. Look for designs with soft grips and balanced weight. A well-shaped handle improves control and reduces slips. Test how the driver feels in your hand. Pick one that is easy to hold and steady during use.

Additional Features

Extra features add value to your impact driver. LED lights help see dark spaces clearly. Variable speed controls give better power management. Some models include belt clips for easy carrying. Brushless motors last longer and need less maintenance. These features improve your work experience and tool lifespan.

Maximizing Torque Efficiency

Maximizing torque efficiency means using your impact driver to its full power without wasting energy. Proper torque use helps you finish tasks faster and protects your tool. It also prevents damage to screws and materials.

Small adjustments can improve torque output and save effort. Focus on the right accessories and tool care. Use settings that match the job. These steps make your work easier and extend the tool’s life.

Proper Bit Selection

Choose the right bit for each screw type and size. A loose bit reduces torque and may strip screws. Use high-quality bits made for impact drivers. Match the bit shape to the screw head exactly. This keeps torque focused and effective.

Maintenance Tips

Clean the impact driver regularly to avoid dust buildup. Check the chuck and bits for wear or damage. Lubricate moving parts as needed. Replace worn bits quickly. Well-maintained tools deliver consistent torque and last longer.

Using Torque Settings

Select torque settings based on the material and screw size. Low torque works for soft materials to avoid damage. Higher torque suits tough materials and large screws. Adjust settings step-by-step to find the best power for each task.

Common Torque Myths

Many people believe torque is the most important factor in choosing an impact driver. This idea leads to some common myths. These myths can confuse beginners and even experienced users. Understanding these myths helps you pick the right tool for your needs.

More Torque Always Better

More torque does not always mean better performance. Too much torque can damage screws or materials. It can also make the tool harder to control. Choose torque based on the job, not just the highest number.

Torque Guarantees Durability

High torque does not guarantee that a tool lasts longer. Durability depends on build quality and materials. A well-made driver with moderate torque can last for years. Focus on brand reputation and user reviews for durability clues.

Torque Replaces Skill

Torque cannot replace good technique and skill. Proper handling and knowledge matter more than raw power. Skilled users can do better work with less torque. Practice and patience improve results more than torque alone.

Credit: axatool.com

Frequently Asked Questions

What Torque Is Ideal For Home Diy Projects?

For home DIY tasks, an impact driver with 1,200 to 1,500 inch-pounds of torque is ideal. It handles most fastening needs without being too powerful or heavy, offering a good balance between control and strength.

How Much Torque Do Professional Impact Drivers Provide?

Professional impact drivers usually offer between 1,500 and 2,000 inch-pounds of torque. This range suits heavy-duty tasks like construction, where stronger fastening and quicker work are essential for efficiency.

Can Too Much Torque Damage Screws Or Materials?

Yes, excessive torque can strip screws or damage materials. Using an impact driver with adjustable torque settings helps prevent over-tightening and ensures safer, more precise fastening for different projects.

What Torque Do I Need For Automotive Repairs?

For most automotive repairs, an impact driver with 1,200 to 1,800 inch-pounds of torque works well. It provides enough power to remove and tighten bolts without risking damage to vehicle components.

Conclusion

Choosing the right torque for your impact driver matters a lot. Too little torque can cause slow work or damage. Too much torque can make tasks harder to control. Think about the jobs you do most. Light tasks need less torque, heavy tasks need more power.

Knowing your needs helps pick the best tool. This saves time and makes your work easier. Remember, the right torque keeps your projects safe and smooth. Keep it simple, and your impact driver will serve you well.