Are you struggling to get precise holes with your drill press? Adjusting your drill press correctly can make all the difference between a sloppy job and a perfect finish.

Whether you’re a beginner or just need a quick refresher, knowing how to adjust your drill press will save you time and frustration. In this guide, you’ll discover simple steps to fine-tune your machine for accurate, clean drilling every time.

Keep reading to unlock the secrets that will make your next project easier and more professional.

Credit: www.reddit.com

Choosing The Right Drill Press

Choosing the right drill press is important for successful drilling tasks. The right drill press saves time and effort. It also improves safety and accuracy. Understanding the types and key features helps you pick the best one for your needs.

Types Of Drill Presses

Drill presses come in many types. Each type suits different jobs and skill levels. A bench drill press fits on a workbench. It is small and good for light tasks. A floor drill press stands on the floor. It is larger and more powerful. A magnetic drill press is portable. It uses magnets to stick to metal surfaces. This type is ideal for metalwork in tight spots. Choosing the type depends on your workspace and project size.

Key Features To Consider

Look at the drill press speed options. Variable speed helps match the drill speed to the material. Check the drill press table size and adjustability. A bigger table gives more support for large workpieces. The spindle travel distance matters. It shows how deep the drill can go. Also, consider the motor power. More power means it can handle harder materials. Safety features like guards and emergency stops are important too. These protect you during use.

Setting Up Your Drill Press

Setting up your drill press correctly is the first step to safe and accurate drilling. A well-prepared machine helps you work faster and avoid mistakes. Take time to check each part before starting. This ensures everything is ready for the task ahead.

Securing The Drill Press

Place the drill press on a strong, flat surface. Use bolts or clamps to fix it firmly in place. This stops the machine from moving during use. A steady drill press gives you better control and cleaner holes. Check that it does not wobble at all.

Installing The Correct Chuck

Choose the right chuck for your drill bit size and type. Remove the old chuck carefully by loosening the screw inside. Slide the new chuck onto the spindle and tighten it well. Make sure the chuck holds the drill bit tightly. Loose chucks can cause the bit to slip or break.

Aligning The Drill Bit

Aligning the drill bit is a key step in adjusting a drill press. Proper alignment ensures clean, accurate holes and reduces wear on the drill bit. Misalignment can cause uneven holes and damage the material. This section covers how to center the bit and check for runout.

Centering The Bit

First, loosen the chuck and insert the drill bit. Tighten it just enough to hold the bit. Lower the bit to the drill press table or a center punch mark. Adjust the table or bit so the tip is exactly over the mark. Rotate the chuck slowly by hand. Watch the bit tip’s movement carefully. If it wobbles, adjust the chuck or bit until it stays centered. Tighten the chuck firmly to lock the bit in place.

Checking For Runout

Runout means the bit spins off-center. It causes uneven holes and faster bit wear. Use a dial indicator or a simple test method. Place the drill bit close to a fixed point. Slowly rotate the bit by hand. Watch for side-to-side movement. If runout exists, loosen the chuck and reposition the bit. Tighten the chuck again and recheck. Repeat until the bit spins smoothly without wobbling.

Credit: www.youtube.com

Adjusting The Table

The table of a drill press holds your workpiece steady during drilling. Adjusting the table correctly improves accuracy and safety. It moves up and down and can tilt to different angles. Understanding how to set the height and angle helps achieve precise drilling results.

Height And Angle Settings

To adjust the height, loosen the table lock handle. Slide the table up or down the column to the needed height. Tighten the handle to secure the table in place. For angle adjustment, loosen the tilt lock. Tilt the table to the desired angle using the scale. Re-tighten the lock to keep the angle fixed. Proper height and angle settings help drill holes at the right depth and direction.

Locking The Table In Place

After setting the height and angle, lock the table firmly. Use the table lock handle to prevent any movement. A loose table can cause inaccurate holes or damage. Check the lock before starting your drill press work. A steady table ensures safety and precise drilling every time.

Calibrating The Depth Stop

Calibrating the depth stop on a drill press ensures every hole has the perfect depth. It helps avoid drilling too deep or too shallow. This adjustment is key for consistent and safe work. Proper calibration saves time and materials. Let’s explore how to set and fine-tune the depth stop for best results.

Setting Drilling Depth

Start by loosening the depth stop lock. Move the depth stop to the desired drilling depth. Use a ruler or depth gauge to measure accurately. Tighten the lock to secure the stop in place. Test by lowering the drill bit to the stop. Adjust if the depth is not exact.

Fine-tuning For Precision

Make small adjustments to the depth stop for better accuracy. Use a test piece of wood to check the hole depth. Compare the hole depth with your target measurement. Turn the depth stop screw slightly to correct the depth. Repeat testing until the depth matches perfectly. This step ensures precise drilling every time.

Maintaining Drill Press Accuracy

Maintaining drill press accuracy is key for precise drilling work. A drill press can lose accuracy over time due to dirt, wear, and lack of care. Regular maintenance keeps the machine running smoothly and cuts clean, straight holes every time.

Regular Cleaning And Lubrication

Clean the drill press after each use. Remove dust, metal shavings, and grease buildup. Use a soft brush or cloth to wipe surfaces. Avoid harsh chemicals that can damage parts.

Lubricate moving parts like the spindle, quill, and gears. Use machine oil or grease as recommended in the manual. Proper lubrication reduces friction and prevents rust. This keeps the drill press moving smoothly and precisely.

Inspecting Components For Wear

Check belts, pulleys, and bearings regularly. Look for cracks, frays, or signs of wear. Replace damaged parts quickly to avoid bigger problems. Worn components cause wobbling and misalignment.

Ensure the table and spindle remain stable and secure. Tighten loose bolts or screws. Properly aligned parts ensure the drill bit stays straight. This maintains drilling accuracy and extends tool life.

Troubleshooting Common Issues

Troubleshooting common drill press issues helps keep your work precise and safe. Problems often come from small errors in setup or wear. Fixing these stops damage to materials and tools.

Drill Bit Wandering

Drill bit wandering happens when the bit slips off the mark. Check if the drill bit is sharp and correctly secured. Dull bits cause more wandering than sharp ones. Make sure the drill press table is stable and the workpiece is clamped tightly. Use a center punch to make a small dent on the drilling spot. This helps guide the bit and stops it from moving.

Inconsistent Hole Depths

Inconsistent hole depths can ruin a project. Set the drill press depth stop correctly before starting. Check the depth gauge for any damage or looseness. If the feed handle moves too easily, tighten it to control the depth better. Use a drill bit with a built-in depth stop for uniform holes. Test on scrap material to confirm settings before drilling the final piece.

Credit: www.homemadetools.net

Frequently Asked Questions

How Do I Set The Drill Press Depth Stop?

To set the depth stop, loosen the stop collar on the quill. Slide it to the desired depth. Tighten the collar securely to prevent movement during drilling.

What’s The Best Way To Align The Drill Press Table?

Loosen the table locking lever. Adjust the table so it’s perpendicular to the drill bit. Use a square for precise alignment. Tighten the lever firmly after adjusting.

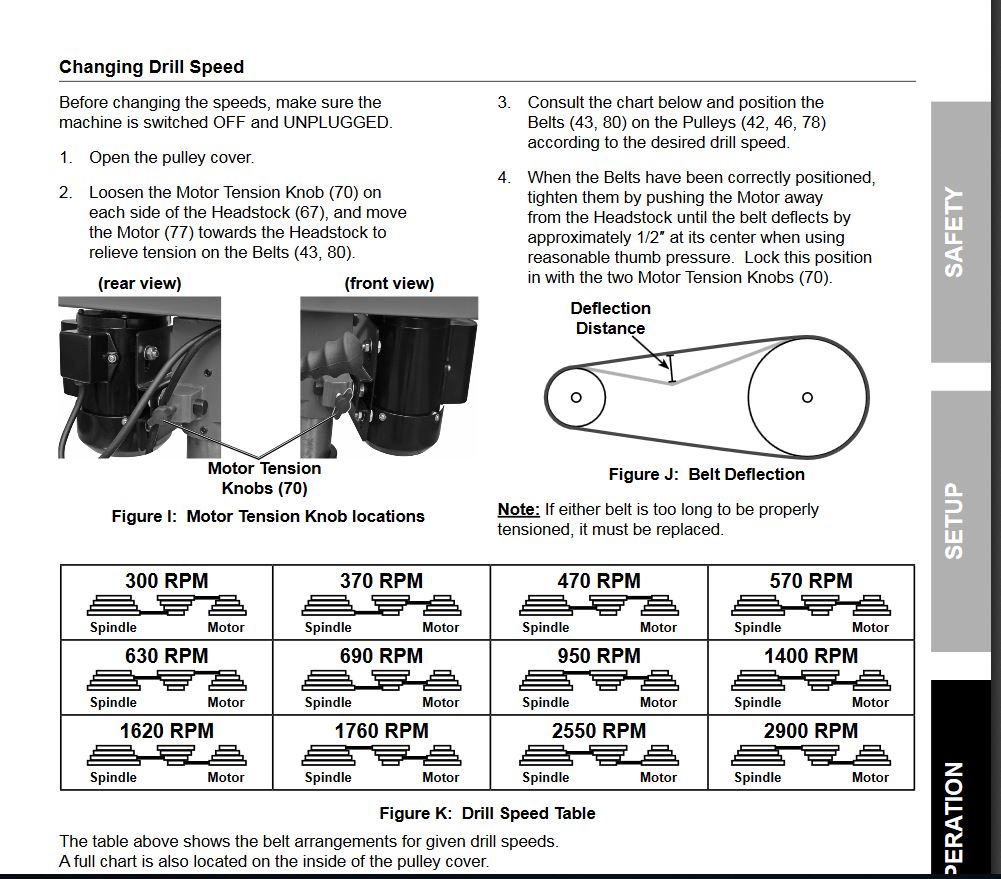

How Do I Adjust Drill Press Speed Correctly?

Check the drill press manual for speed settings. Adjust the belt position on pulleys or use variable speed controls. Match speed to material type for clean drilling.

How Can I Ensure Drill Bit Is Centered Properly?

Loosen the chuck and insert the drill bit. Tighten it evenly while ensuring the bit is straight. Rotate the chuck slowly to verify centering.

Conclusion

Adjusting a drill press takes patience and careful steps. Start by loosening the right parts gently. Align the drill bit with your workpiece carefully. Tighten the settings firmly but without force. Check your adjustments before you start drilling. Small tweaks can improve your drilling accuracy.

Practice a few times to feel confident. This helps you avoid mistakes and saves time. A well-set drill press makes your projects easier. Keep your tools clean and maintained for best results. Safety matters—always wear protective gear while working.