If you want to take your drilling projects to the next level, attaching a drill press vise to your drill press is a game-changer. It keeps your workpiece steady, boosts precision, and makes your job safer and easier.

But if you’re unsure how to secure the vise correctly, you might waste time or risk damage. This guide will walk you through simple, clear steps to attach your drill press vise quickly and securely. By the end, you’ll have the confidence to get your vise set up right and start drilling like a pro.

Keep reading to discover how to make your drill press work smarter for you.

Choosing The Right Drill Press Vise

Choosing the right drill press vise is key for safe and precise work. The right vise holds your material steady and fits your drill press perfectly. Not all vises work for every drill press. Understanding your options helps you pick the best one.

Types Of Drill Press Vises

There are several types of drill press vises. A standard drill press vise is common and holds materials firmly with a screw mechanism. A swivel vise can rotate, which helps with angled drilling. A quick-release vise opens and closes fast, saving time on adjustments. Each type suits different tasks and needs.

Factors To Consider

Material size and shape matter when choosing a vise. Look for a vise that grips your workpiece securely. Check the vise’s jaw width and opening size. Strong clamping force keeps materials from moving. Also, consider the vise’s build quality. Steel vises offer durability. Plastic or aluminum vises may be lighter but less sturdy.

Matching Vise Size To Drill Press

The vise should match your drill press table size. A large vise might not fit on a small table. A small vise may not hold bigger workpieces well. Measure your drill press table before buying. Make sure the vise base fits and clamps securely to the table. Proper fit ensures stability and safety during use.

Preparing Your Drill Press

Preparing your drill press is the first step before attaching a drill press vise. A clean and clear workspace helps ensure safety and precision. Taking time to prepare the drill press will make the installation process smooth. Follow these steps to get your drill press ready.

Cleaning The Drill Table

Start by removing dust and debris from the drill table. Use a brush or cloth to clear all dirt. Cleaning prevents slipping and ensures the vise sits flat. A clean surface improves accuracy during drilling tasks.

Removing Existing Accessories

Check the drill table for any tools or clamps. Remove all accessories that may block the vise. Clearing the table gives you room to position the vise properly. It also prevents damage to other equipment.

Checking Drill Press Compatibility

Confirm the drill press table size matches your vise base. Check if the drill press has T-slots or holes for mounting. Make sure the vise fits securely without wobbling. Compatibility is key for safe and steady drilling.

Gathering Necessary Tools And Materials

Before attaching a drill press vise to your drill press, gather all needed tools and materials. Preparation saves time and avoids frustration. Having everything ready makes the installation smooth. This section covers the essential tools, safety gear, and optional accessories you may want.

List Of Required Tools

First, collect the basic tools needed for the job. A wrench or socket set fits the bolts securing the vise. A screwdriver may be required for smaller screws. A measuring tape helps position the vise accurately. A center punch marks drilling spots if needed. A hammer assists with the punch. Keep these tools close for easy access.

Safety Equipment

Safety is important during installation. Wear safety goggles to protect your eyes from metal chips. Gloves shield your hands from sharp edges. Hearing protection reduces noise from hammering or drilling. Use a dust mask if you create dust or particles. Always prioritize safety to prevent injuries.

Optional Accessories

Some extra items can help with the process. Clamps hold the vise steady while tightening bolts. A level ensures the vise sits flat and straight. Thread locker keeps bolts from loosening over time. A small brush cleans metal surfaces before attaching the vise. These accessories improve accuracy and durability.

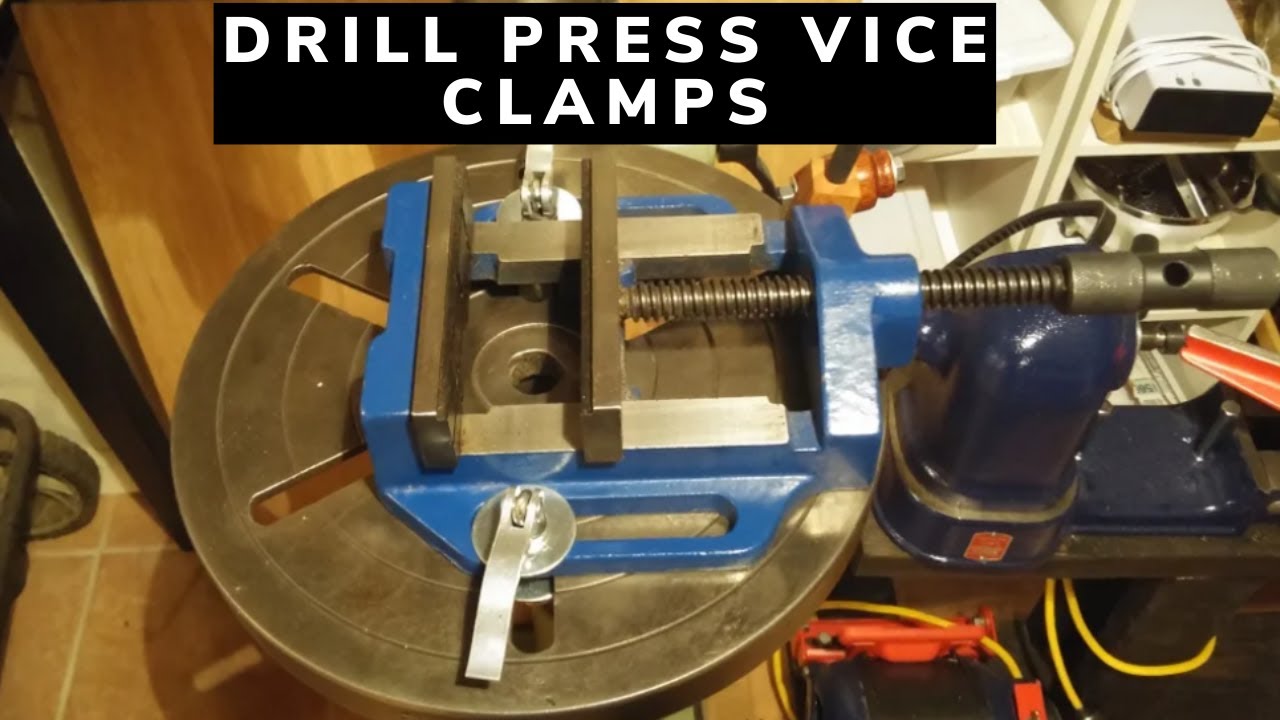

Credit: www.youtube.com

Positioning The Vise On The Drill Table

Positioning the vise on the drill table is a key step for safe and accurate drilling. The right placement ensures the workpiece stays steady. It also helps keep the drill bit aligned. Taking time to position the vise carefully will improve your results. Follow these steps to place the vise correctly on the table.

Aligning The Vise

Place the vise on the drill table close to the drill bit. Make sure the jaws face the right direction. The vise should line up with the drill bit’s path. Check that the vise is straight and not tilted. Proper alignment keeps your holes precise and clean.

Ensuring Stability

Check if the vise sits flat on the table. The surface must be even to avoid wobbling. Tighten the vise’s base or clamps to hold it firm. Avoid any movement during drilling. Stability protects both your workpiece and the drill press.

Marking Mounting Points

Mark the spots where you will fix the vise. Use a pencil or marker for clear marks. These points guide drilling holes or placing bolts. Double-check the marks to keep the vise steady. Accurate marking helps in quick and safe mounting.

Securing The Vise

Securing the vise on a drill press is essential for safe and accurate drilling. A firmly attached vise keeps your workpiece steady. It prevents slips and mistakes during drilling. Follow clear steps to attach the vise properly to your drill press table.

Using T-slots And Bolts

Most drill press tables have T-slots. These slots hold bolts that secure the vise. Slide the vise base into the T-slot. Align the holes in the vise with the slot. Insert the bolts through these holes. Tighten the bolts to hold the vise firmly. This method provides a stable setup for your drilling tasks.

Clamping Techniques

Clamps add extra security to the vise. Place clamps on both sides of the vise base. Press the clamps down firmly onto the table. Use clamps if your drill press lacks T-slots. Ensure the vise does not move or shift. Clamping helps keep the vise steady during powerful drilling jobs.

Tightening For Safety

Always tighten all bolts and clamps fully. Loose attachments can cause the vise to move. A moving vise risks damaging the workpiece and the drill bit. Use a wrench or a screwdriver to ensure tightness. Check the tightness before starting each drilling task. Safety depends on a well-secured vise.

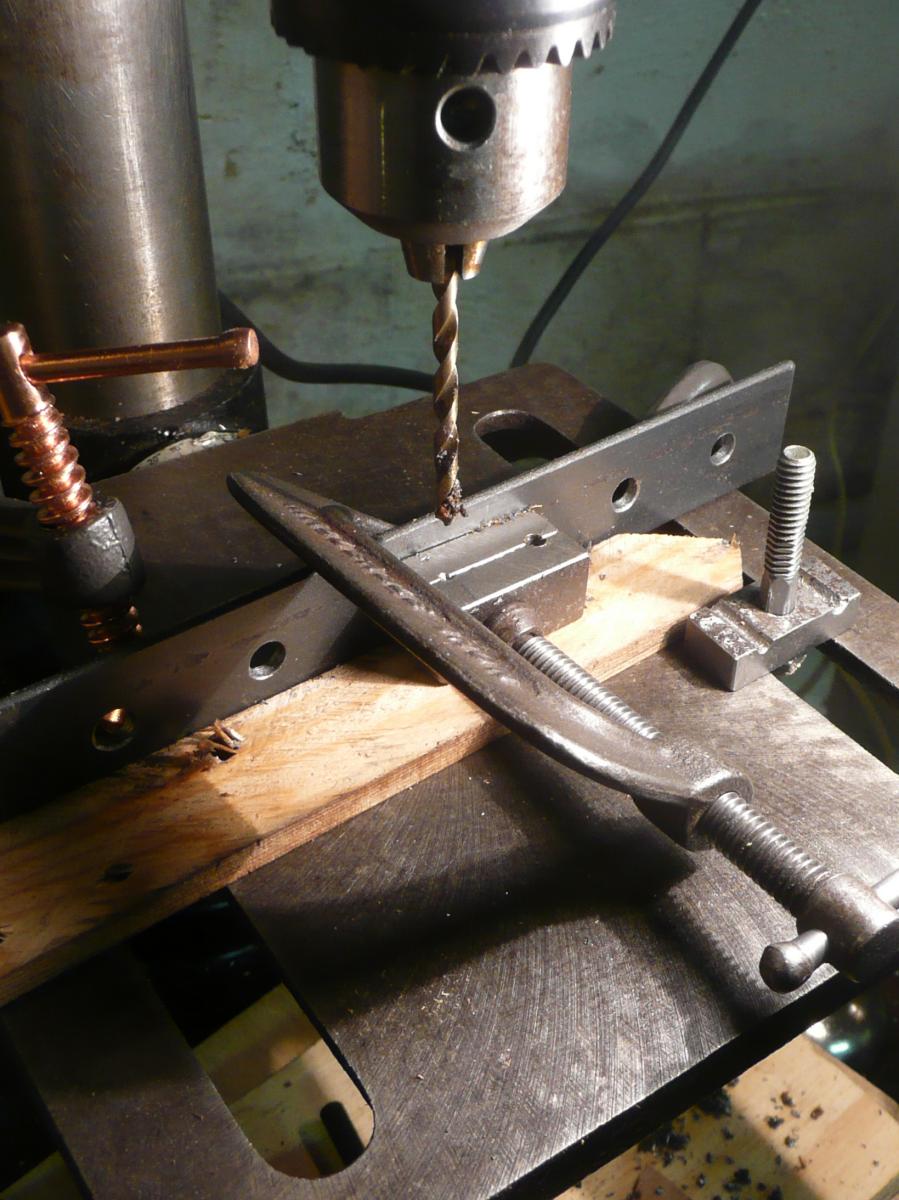

Credit: www.reddit.com

Adjusting The Vise For Accuracy

Adjusting the vise for accuracy is key to getting precise drill holes. A well-set vise keeps your workpiece steady and aligned. Small adjustments here make a big difference in your drilling results.

Checking Alignment With The Drill Bit

First, place the workpiece in the vise and close the jaws gently. Lower the drill bit slowly until it almost touches the workpiece. Look carefully to see if the bit lines up with the spot you want to drill. Move the vise slightly if the bit is off-center. Repeat this step until the bit is perfectly aligned.

Fine-tuning Vise Position

Loosen the vise mounting bolts just enough to shift the vise. Slide or rotate the vise in small steps to improve alignment. Tighten the bolts slightly after each adjustment. Check the bit alignment again. Keep adjusting and tightening until the vise holds the workpiece exactly where you want it.

Testing Clamping Pressure

Check how tight the vise grips the workpiece. The pressure should be firm but not too strong to damage the material. Try to move the workpiece by hand. It should not shift or wiggle. Adjust the vise handle to increase or decrease clamping force. Proper pressure ensures safety and accuracy during drilling.

Maintenance Tips For Drill Press Vises

Maintaining your drill press vise is key to keeping it working well. Proper care helps the vise last longer and hold materials firmly. Small steps in upkeep save time and money over time.

Cleaning And Lubrication

Clean the vise after every use. Remove dust, metal shavings, and dirt with a brush or cloth. Avoid water to stop rust. Use light machine oil on moving parts. This reduces friction and prevents wear.

Regular Inspection

Check the vise regularly for wear or damage. Look for cracks, loose screws, or bent parts. Tighten any loose bolts. Replace damaged parts quickly to keep the vise safe and effective.

Troubleshooting Common Issues

If the vise does not hold tight, check the jaw alignment. Misaligned jaws cause slipping. Clean and re-lubricate the screw if it feels stiff. Listen for unusual noises that could mean problems. Address issues early to avoid bigger repairs.

Credit: homepage.cs.uiowa.edu

Frequently Asked Questions

How Do I Secure A Drill Press Vise Properly?

To secure a drill press vise, align it on the drill press table. Use bolts or clamps to fasten it tightly. Ensure the vise is stable and does not move during drilling for safety and precision.

What Tools Are Needed To Attach A Drill Press Vise?

You typically need a wrench, bolts, and clamps to attach a drill press vise. Sometimes, a screwdriver or Allen key is necessary. These tools help fix the vise firmly to the drill press table.

Can I Attach Any Vise To A Drill Press?

Not all vises fit every drill press. Choose a vise compatible with your drill press size and table. Check the mounting hole pattern to ensure proper attachment and secure fit.

How To Align The Vise For Accurate Drilling?

Place the vise square to the drill press table. Use a try square to check alignment. Adjust the vise until it is perfectly perpendicular to the drill bit for precise drilling.

Conclusion

Attaching a drill press vise to your drill press is simple and safe. Secure the vise tightly to avoid movement during use. Check the alignment to ensure precise drilling every time. A well-attached vise helps you work faster and cleaner.

Take your time to set it up correctly. This small step improves your drilling projects a lot. Keep your workspace organized and tools ready. Enjoy better control and accuracy with your drill press vise.