Are you struggling with a stuck ignition lock cylinder and wondering if drilling it out is your only option? Before you panic, this guide will walk you through the steps to drill your ignition lock cylinder safely and effectively.

You’ll learn exactly what tools you need, how to avoid damaging your vehicle, and what to expect during the process. If you want to regain control of your car without spending a fortune on a locksmith, keep reading—this article is made just for you.

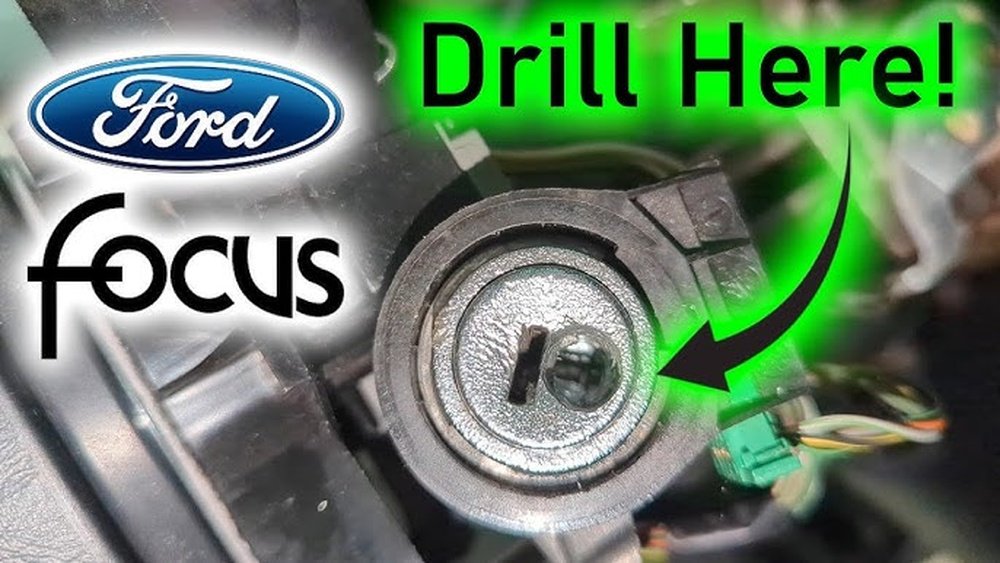

Credit: www.youtube.com

Tools Needed

Drilling an ignition lock cylinder needs specific tools. These tools make the job easier and safer. Knowing what tools to use helps avoid damage and saves time. Below are the main tools required for this task.

Drill Types

A corded drill offers steady power and control. It works well for drilling through metal locks. A cordless drill gives more freedom of movement. But it may have less power. Choose a drill with variable speed settings. This allows better control while drilling.

Drill Bits

Use high-speed steel (HSS) drill bits for metal locks. A 3/16-inch bit is a good starting size. You may need to use larger bits to finish the job. Step drill bits also work well for this task. They create clean holes and reduce damage risk.

Safety Gear

Wear safety glasses to protect your eyes from metal shards. Gloves protect your hands from sharp edges and heat. Hearing protection is important if the drill is loud. Use a dust mask to avoid inhaling metal dust. Safety gear reduces injury risk during drilling.

Preparing The Lock

Preparing the lock is an important first step before drilling the ignition lock cylinder. It helps to work safely and avoid damage to other parts. Taking time to prepare the lock makes the drilling process smoother.

Removing Surrounding Components

Start by removing parts around the lock cylinder. These parts can block access or get damaged during drilling. Use basic tools like screwdrivers or pliers to take off covers and panels carefully. Keep all screws and parts safe for reassembly.

Clear space around the lock cylinder. This gives better visibility and control. It also protects other components from metal shavings or accidental hits.

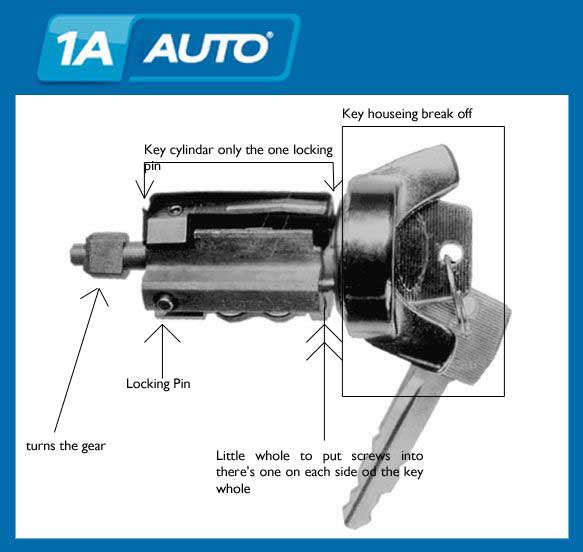

Securing The Lock Cylinder

Hold the lock cylinder firmly to stop it from moving. Use a clamp or vise if possible. A steady lock cylinder reduces errors and helps drill in the right spot.

Check the lock cylinder’s position. Align it so the drill bit hits the correct area. Proper securing improves accuracy and speeds up the drilling process.

Marking Drill Points

Marking drill points is a key step before drilling an ignition lock cylinder. It helps you drill in the right spots. Proper marking reduces mistakes and protects the lock’s internal parts.

Clear marks guide your drill bit and make the job easier. Precise points save time and prevent damage to the cylinder.

Identifying Weak Spots

Look closely at the lock cylinder. Find spots that seem thinner or softer. These weak spots are easier to drill through. Focus on areas around the keyhole and pins inside the lock. Avoid drilling too close to strong metal parts. Weak spots help you break the lock faster and with less effort.

Using A Center Punch

A center punch makes small dents on the drill points. These dents stop the drill bit from slipping. Place the punch on the marked spot. Tap it gently with a hammer. The dent guides the drill bit straight into the lock. This step improves accuracy and safety while drilling.

Drilling Process

Drilling an ignition lock cylinder requires care and precision. The drilling process is the key step to remove the lock cylinder safely. Following the right method helps avoid damage to the car or lock system.

Focus on the drill speed, pressure, and angle. Each factor affects the outcome and ease of the job. Proper drilling ensures the cylinder can be removed quickly and cleanly.

Setting Drill Speed

Choose a low to medium drill speed. High speed can overheat the metal and ruin the lock. Slow drilling gives better control and accuracy. Start slow, then adjust if needed. Consistent speed helps prevent slips and mistakes.

Applying Pressure

Use steady, firm pressure on the drill. Too much force can break the drill bit or damage the lock. Too little pressure slows down the work. Keep the pressure even to drill through the pins inside. Let the drill do the work without pushing hard.

Drilling At Correct Angles

Hold the drill perpendicular to the lock surface. Angled drilling can cause damage or miss key parts. Keep the drill straight for clean holes. Adjust your hand position to maintain the angle. Correct angles make the cylinder easier to remove after drilling.

Removing The Cylinder

Removing the ignition lock cylinder is a key step in the drilling process. It allows you to access the internal parts safely. This section explains how to remove the cylinder using basic tools. Follow these tips carefully to avoid damage.

Using Pliers Or Extractors

Start by locating the retaining clip or screw that holds the cylinder. Use pliers or a special extractor tool to grip the cylinder firmly. Pull the cylinder straight out with steady force. Avoid twisting too much to prevent breaking the lock. If the cylinder moves slowly, wiggle it gently while pulling.

Handling Stuck Cylinders

Stuck cylinders need extra care to avoid damage. Spray a small amount of lubricant around the lock area. Let it sit for a few minutes to loosen the parts. Use a flathead screwdriver to pry the edges carefully. Apply steady pressure but do not force it. Repeat the process until the cylinder comes free.

Credit: www.experts-exchange.com

Safety Tips

Drilling an ignition lock cylinder can be tricky and dangerous. Safety must be your top priority. Taking the right precautions helps protect you and your vehicle. It also keeps the work area clean and safe. Follow these safety tips to avoid accidents and damage.

Protecting Yourself

Wear safety glasses to protect your eyes from metal shards. Use gloves to avoid cuts and burns. Work in a well-lit area to see clearly. Keep your body parts away from the drill bit. Stand steady to maintain control of the drill. Take breaks if you feel tired or distracted.

Avoiding Damage To Vehicle

Cover nearby surfaces with tape to prevent scratches. Mark the exact spot to drill to avoid mistakes. Use the correct drill bit size for the lock cylinder. Drill slowly and carefully to control depth. Avoid drilling too deep to protect internal parts. Disconnect the battery to prevent electrical problems.

Dealing With Debris

Clear metal shavings often to avoid buildup. Use a small brush or vacuum to clean the area. Keep debris away from your eyes and mouth. Dispose of metal pieces safely to prevent injury. Clean the lock cylinder area before reinstalling parts. Maintain a tidy workspace for better focus.

After Drilling Care

After drilling the ignition lock cylinder, proper care is crucial. It ensures your vehicle’s ignition works smoothly. Neglecting this step may cause damage or malfunction. Follow these simple steps to maintain the area and install a new cylinder correctly.

Cleaning The Area

Remove all metal shavings and debris carefully. Use a small brush or compressed air. Clean the drilled hole thoroughly to avoid blockages. Wipe the surrounding surface with a clean cloth. This prevents dirt from entering the ignition system.

Installing A New Cylinder

Choose a compatible ignition lock cylinder for your vehicle. Align the new cylinder with the drilled hole. Insert it slowly, ensuring a snug fit. Secure the cylinder with screws or clips as needed. Test the key to confirm smooth operation. Proper installation prevents future ignition problems.

Common Mistakes To Avoid

Drilling an ignition lock cylinder requires care and precision. Many beginners make errors that can cause damage or waste time. Avoiding common mistakes helps the process go smoothly and safely.

Overheating The Drill Bit

Drilling too fast causes the bit to overheat. Hot drill bits lose sharpness quickly. This makes drilling harder and can damage the lock. Use slow, steady pressure and take breaks to cool the bit.

Incorrect Drill Bit Size

Using the wrong drill bit size can ruin the lock cylinder. A bit too large can break the lock or the key mechanism. A bit too small wastes time and effort. Choose a bit size that matches the lock’s pins carefully.

Rushing The Process

Trying to drill quickly leads to mistakes and damage. Patience is essential. Rushing can cause the drill to slip or break pins inside. Take your time to keep control and ensure a clean drill.

Credit: myfuse.education

Frequently Asked Questions

How Do You Safely Drill An Ignition Lock Cylinder?

To drill an ignition lock cylinder safely, use a drill bit slightly smaller than the keyhole. Drill slowly at low speed to avoid damage. Always wear safety goggles and protect surrounding components. This method helps to remove the cylinder without harming the ignition switch.

What Tools Are Needed To Drill An Ignition Lock?

You need a power drill, drill bits (preferably cobalt), safety goggles, and a screwdriver. A center punch helps mark the drilling spot. These tools ensure precision and safety during the ignition lock cylinder drilling process.

Can Drilling An Ignition Lock Damage The Ignition Switch?

Yes, improper drilling can damage the ignition switch or wiring. Use the correct drill bit size and drill carefully. Avoid excessive force and overheating to prevent internal damage. Proper technique minimizes risks and preserves the vehicle’s electrical system.

Why Would You Need To Drill An Ignition Lock Cylinder?

Drilling is necessary when the ignition lock cylinder is jammed, broken, or the key is lost. It allows removal of the faulty cylinder for replacement. This method is a last resort when other unlocking methods fail.

Conclusion

Drilling an ignition lock cylinder requires care and the right tools. Always follow safety steps to avoid damage. Take your time and work slowly for best results. Practice on old locks if possible to gain confidence. Remember, this method should be a last resort.

Knowing how to drill the lock helps in emergencies. Stay calm and focused throughout the process. This guide gives you clear steps to handle the task safely. Keep your tools ready and be patient. You can manage this job with some effort and care.