Have you ever found yourself locked out with no key in sight? It’s frustrating, stressful, and sometimes feels hopeless.

But what if you could take control and get back inside quickly? Learning how to drill out a lock might sound tricky, but with the right steps, you can do it safely and effectively. In this guide, you’ll discover simple, clear instructions to help you break free without causing unnecessary damage.

Keep reading, because your solution is closer than you think.

Credit: www.youtube.com

Tools Needed

Drilling out a lock requires the right tools to do the job safely and effectively. Having the proper equipment helps you work faster and avoid damage. Understanding the tools needed is the first step.

Types Of Drill Bits

Choose drill bits designed for metal. A high-speed steel (HSS) bit works well for most locks. For tougher locks, use cobalt drill bits. Start with a small bit to make a pilot hole. Then, switch to a larger bit to drill out the lock cylinder. Sharp bits make drilling easier and cleaner.

Safety Gear

Protect your eyes with safety goggles. Metal shavings can cause serious injury. Wear gloves to protect your hands from sharp edges. Use ear protection to reduce noise from the drill. A dust mask prevents inhaling small metal particles during drilling.

Additional Equipment

A power drill with adjustable speed is essential. Cordless drills offer more mobility. A center punch helps mark the spot to drill accurately. Keep a sturdy work surface to hold the lock steady. A small brush or compressed air cleans metal shavings from the lock.

Credit: www.wikihow.com

Preparing The Lock

Preparing the lock is the first step before drilling it out. This step helps you work safely and effectively. It also reduces the risk of damaging your door or surrounding parts.

Proper preparation saves time and effort during drilling. It ensures you target the right area on the lock. Understanding the lock type and marking the drill spot are key parts of this process.

Assessing The Lock Type

Identify the lock type before drilling. Common types include cylinder, deadbolt, and padlocks. Each type needs a different drilling approach.

Check the lock for visible screws or bolts. Some locks have protective covers that must be removed. Knowing the lock type helps you choose the right drill bit size.

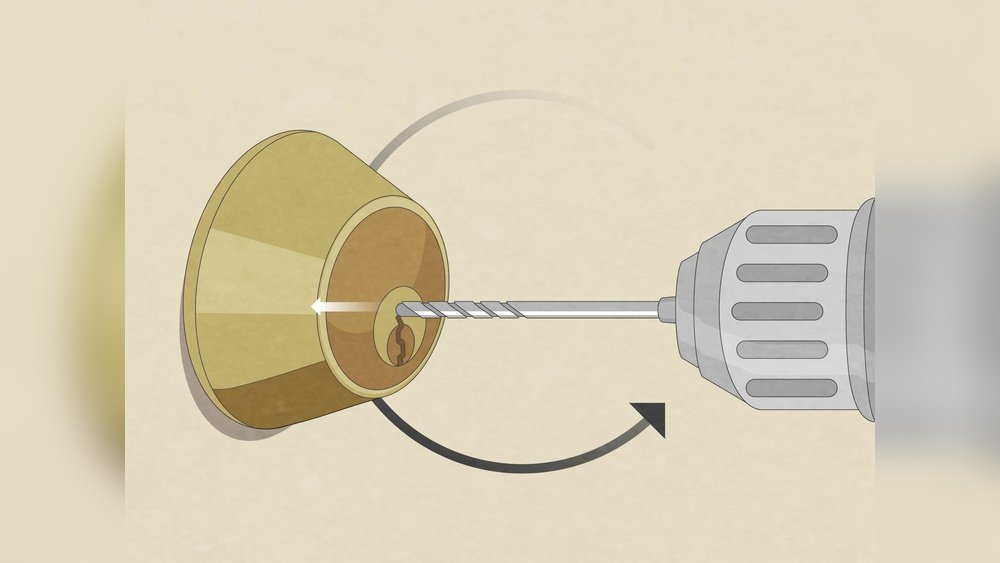

Marking The Drill Spot

Find the exact spot to drill on the lock. Usually, this is near the keyhole or cylinder center. Use a marker or pencil to mark the spot clearly.

Marking guides the drill and prevents mistakes. A small indentation with a nail or punch helps keep the drill bit steady. Accurate marking leads to a cleaner, easier drilling process.

Drilling Techniques

Drilling techniques play a key role in drilling out a lock safely and effectively. Using the right method helps avoid damage and makes the process faster. This section covers important tips on drill speed, pressure, angle, and positioning to guide you through the task.

Drill Speed And Pressure

Keep the drill speed moderate to maintain control. Too fast can overheat the drill bit or lock. Too slow may cause the bit to get stuck.

Apply firm but steady pressure. Pressing too hard risks breaking the bit. Light pressure slows progress and causes slipping.

Angle And Positioning

Hold the drill straight and steady, aiming at the lock cylinder center. A wrong angle can damage the lock or drill bit.

Position the drill bit right where the pins are inside the lock. This spot is usually just above the keyhole.

Removing Lock Components

Removing lock components is a key step in drilling out a lock. It helps you clear the way for a new lock or repair. This process requires care and the right tools. Small mistakes can damage the door or lock further.

Start by breaking the cylinder. Then carefully extract the lock parts. Follow each step slowly to avoid extra damage. Understanding these parts will make the job easier and safer.

Breaking The Cylinder

The cylinder is the round part where you insert the key. Use a drill with a metal bit to break it. Drill straight into the center of the cylinder. Apply steady pressure and keep the drill level. The goal is to destroy the pins inside. This stops the lock from turning and opens the way to remove it.

Work slowly. Too much force can harm the door or frame. Wear safety glasses to protect your eyes from metal shards. Stop drilling once the cylinder is clearly broken.

Extracting The Lock

After breaking the cylinder, the lock becomes loose. Use a screwdriver to remove screws holding the lock in place. Pull the lock body out carefully. If it is stuck, wiggle it gently to free it.

Check for any remaining parts inside the door. Remove all pieces to make space for the new lock. Clean the area before installing a replacement. This helps the new lock fit well and work smoothly.

Post-drilling Steps

After drilling out a lock, several important steps follow to finish the job properly. These steps ensure the door works well and stays secure. Taking time here prevents future problems.

Cleaning The Area

Remove all metal shavings and debris from the drilled hole. Use a brush or vacuum to clear the space. Clean surfaces help the new lock fit correctly. Dirt or metal bits can cause the lock to jam. Wipe the area with a damp cloth to remove fine dust. Let it dry fully before installing the new lock.

Installing A New Lock

Choose a replacement lock that fits your door type and size. Insert the lock carefully into the cleaned hole. Align it with the screw holes for a tight fit. Use the correct screws to secure the lock firmly. Test the lock by turning the key or knob several times. Make sure it operates smoothly without sticking or jamming. Adjust if needed to ensure proper function and security.

Common Mistakes To Avoid

Drilling out a lock is a delicate task. Many people make mistakes that cause damage or waste time. Avoiding these errors helps finish the job faster and safer. Here are some common mistakes to watch out for.

Using The Wrong Drill Bit

Choosing the wrong drill bit can ruin the lock and the drill. Always use a high-speed steel or cobalt bit. These bits cut through metal better. A regular wood bit will dull quickly and cause damage.

Drilling In The Wrong Spot

Drilling in the wrong place makes the lock harder to remove. Study the lock’s mechanism before starting. Aim for the pins inside the cylinder. Drilling the wrong area wastes time and effort.

Applying Too Much Pressure

Pressing too hard can break the drill bit or damage the lock. Use steady, light pressure. Let the drill bit do the work. This prevents slipping and keeps the drill steady.

Not Wearing Safety Gear

Metal shards can fly during drilling. Always wear safety glasses to protect your eyes. Gloves help avoid cuts from sharp edges. Safety gear reduces the risk of injury.

Ignoring Drill Speed Settings

Using the wrong drill speed can overheat the bit. High speeds work well on soft metals. Slow speeds are better for hard metals like steel. Adjust the drill speed to match the lock type.

When To Call A Professional

Drilling out a lock can be tough and risky. Sometimes, it is best to call a professional locksmith. They have the right tools and skills to handle tough locks safely. Knowing when to call a professional can save time and avoid damage to your door or lock.

Signs You Should Call A Locksmith

Locks that are very old or rusty may break during drilling. Professionals know how to work with these types safely. If the lock is part of a security system, drilling might cause more problems. A locksmith can avoid this risk.

When You Lack Proper Tools

Drilling a lock needs special drill bits and tools. Using the wrong tools can damage the door. Professionals come prepared with the right equipment. They complete the job quickly and without extra damage.

To Avoid Damage To Your Door

Drilling can harm the door frame or surrounding area. Experts understand how to protect your door while working. Calling a locksmith helps keep your door intact and secure.

When You Need Quick Access

Lost keys or locked-out situations need fast solutions. A locksmith can open your door quickly without guesswork. They reduce waiting time and stress.

Credit: www.youtube.com

Frequently Asked Questions

How Do I Safely Drill Out A Lock?

To safely drill out a lock, use a drill bit slightly smaller than the lock cylinder. Drill at the center of the keyhole slowly. Wear safety goggles and gloves. Avoid excessive force to prevent damage to the door or surrounding hardware.

What Tools Are Needed To Drill Out A Lock?

You need a power drill, drill bits (starting small, then larger), safety goggles, gloves, and possibly a screwdriver. A center punch can help mark the drilling spot. These tools ensure precision and safety during the lock drilling process.

Can Drilling A Lock Damage My Door?

Drilling can damage the lock and possibly the door if done improperly. Use the correct drill bit and controlled pressure. Avoid drilling too deep or off-center to protect the door’s integrity and reduce repair costs.

Is Drilling Out A Lock A Legal Method To Open It?

Drilling out a lock is legal only if you own the property or have permission. Unauthorized lock drilling can be considered illegal entry or vandalism. Always verify legal rights before attempting to drill a lock.

Conclusion

Drilling out a lock takes care and the right tools. Always wear safety gear to protect your eyes and hands. Take your time and drill slowly to avoid damage. Remember, this method should be used only in emergencies. After drilling, replace the lock to keep your property safe.

Practice patience and stay calm throughout the process. These simple steps help you solve lock problems quickly and safely.