Have you ever found yourself locked out of your own toolbox, with no key in sight? It can be frustrating when you need quick access to your tools but the lock won’t budge.

Don’t worry—you’re not alone, and there’s a solution. In this guide, you’ll learn exactly how to drill out a lock on a toolbox safely and effectively. By following simple steps, you can regain control without damaging your toolbox. Keep reading, and you’ll discover the tips and tricks to get back to work fast.

Credit: www.youtube.com

Tools Needed

To drill out a lock on a toolbox, you need the right tools. Using proper equipment makes the job easier and safer. Each tool has a specific role in the process. Prepare all tools before starting to save time and avoid frustration.

Drill Types

A power drill is the best choice for drilling out locks. Corded drills offer steady power without battery limits. Cordless drills provide flexibility and easy handling. Choose a drill with variable speed settings for better control.

Drill Bits

Use high-speed steel (HSS) drill bits for metal locks. Start with a small bit to create a pilot hole. Then, switch to a larger bit to widen the hole. Step drill bits work well for clean and precise drilling.

Safety Gear

Wear safety glasses to protect your eyes from metal shavings. Gloves help protect your hands from sharp edges and heat. Ear protection reduces noise from the drill. Always dress in clothes that cover your skin fully.

Credit: www.amazon.com

Assessing The Lock

Before drilling out a lock on a toolbox, it is important to assess the lock properly. This helps you choose the right tools and approach. Understanding the lock’s features can save time and reduce damage to your toolbox.

Lock Material

Check what material the lock is made from. Common materials include brass, steel, and zinc alloy. Softer metals like brass are easier to drill through. Harder metals like steel need stronger drill bits.

Knowing the lock material guides your drill bit choice. Use a metal drill bit for steel locks. A high-speed steel bit works well on softer metals.

Lock Type

Identify the type of lock on your toolbox. Padlocks, cam locks, and tubular locks are common types. Each lock type has a different structure inside.

Padlocks usually have a shackle and a locking mechanism. Cam locks have a rotating cam inside. Tubular locks have pins arranged in a circle. Understanding the lock type helps you target the drill correctly.

Positioning

Look at where the lock is placed on the toolbox. The position affects how you hold the drill. Locks on corners or edges need careful handling.

Make sure the toolbox is stable before drilling. Hold the drill steady and apply even pressure. Drilling at the right angle prevents damage to the toolbox body.

Preparing To Drill

Preparing to drill out a lock on a toolbox is an important first step. Proper preparation helps make the process easier and safer. It also protects your toolbox and tools from damage. Take time to get everything ready before starting the drill.

Marking Drill Points

Find the exact spot on the lock to drill. Usually, this is near the keyhole or the center of the lock cylinder. Use a marker or pencil to mark the spot clearly. A precise mark helps guide your drill bit. It prevents slipping and damage to other parts of the toolbox.

Securing The Toolbox

Keep the toolbox steady during drilling. Place it on a flat, stable surface. Use clamps or a vice to hold it firmly. A moving toolbox can cause mistakes or injury. Secure the toolbox tightly but avoid damaging it with too much pressure.

Safety Precautions

Wear safety goggles to protect your eyes from metal shards. Use gloves to protect your hands from sharp edges. Work in a well-ventilated area to avoid breathing dust. Keep your body clear of the drill’s path. Double-check your tools before starting to ensure they are in good condition.

Drilling Technique

Drilling out a lock on a toolbox requires the right technique. It helps you work safely and efficiently. Using the correct drilling method reduces damage and makes the job easier. Follow these key steps for the best results.

Starting The Drill

Place the drill bit on the center of the lock cylinder. Hold the drill steady to avoid slipping. Start drilling at a slow speed. This helps create a small hole without damaging the toolbox. Once the bit grips, increase the speed slightly. Keep the drill straight to ensure accuracy.

Applying Pressure

Apply firm but gentle pressure. Pressing too hard can break the drill bit or damage the lock housing. Let the drill bit do the work. Maintain steady pressure to help the bit cut through the lock pins. Pause if the drill gets too hot. This prevents overheating and extends drill bit life.

Avoiding Damage

Use a drill bit designed for metal. This prevents dulling and slipping. Avoid drilling too deep to protect the toolbox interior. Keep the drill bit cool by stopping occasionally. Use water or oil as a lubricant if needed. Always wear safety goggles to protect your eyes from metal shavings.

Removing The Lock

Removing the lock from a toolbox requires careful steps to avoid damage. The goal is to disable the lock so the toolbox can open. This process involves breaking the lock cylinder and then extracting the internal parts. Each step needs patience and the right tools to be safe and effective.

Breaking The Lock Cylinder

Start by locating the lock cylinder on the toolbox. Use a drill with a metal bit that fits the cylinder size. Drill slowly and steadily into the center of the lock. This action breaks the pins inside the cylinder. Keep drilling until the lock mechanism stops working.

Wear safety glasses to protect your eyes from metal shards. Avoid pressing too hard to prevent slipping. The goal is to destroy the pins, not the entire lock body. This will make the lock easier to remove in the next step.

Extracting Lock Parts

After breaking the cylinder, use a flathead screwdriver or a small pick. Insert it into the broken lock hole. Push or pry out the broken pins and springs inside. Remove all loose parts to clear the lock mechanism.

Take care not to damage the toolbox around the lock area. Clean the space so the toolbox can open freely. Once all pieces are out, test the toolbox latch. It should open without resistance.

After Drilling

After drilling out a lock on a toolbox, some important steps follow. These steps help restore the toolbox’s function and keep it secure. Taking care of the area and the lock ensures long-term use without trouble.

Cleaning The Area

Remove metal shavings and dust from the drilled spot. Use a small brush or cloth to clear all debris. Clean surfaces prevent rust and damage. Check the hole edges for sharp bits and smooth them. This step protects your hands and the new lock.

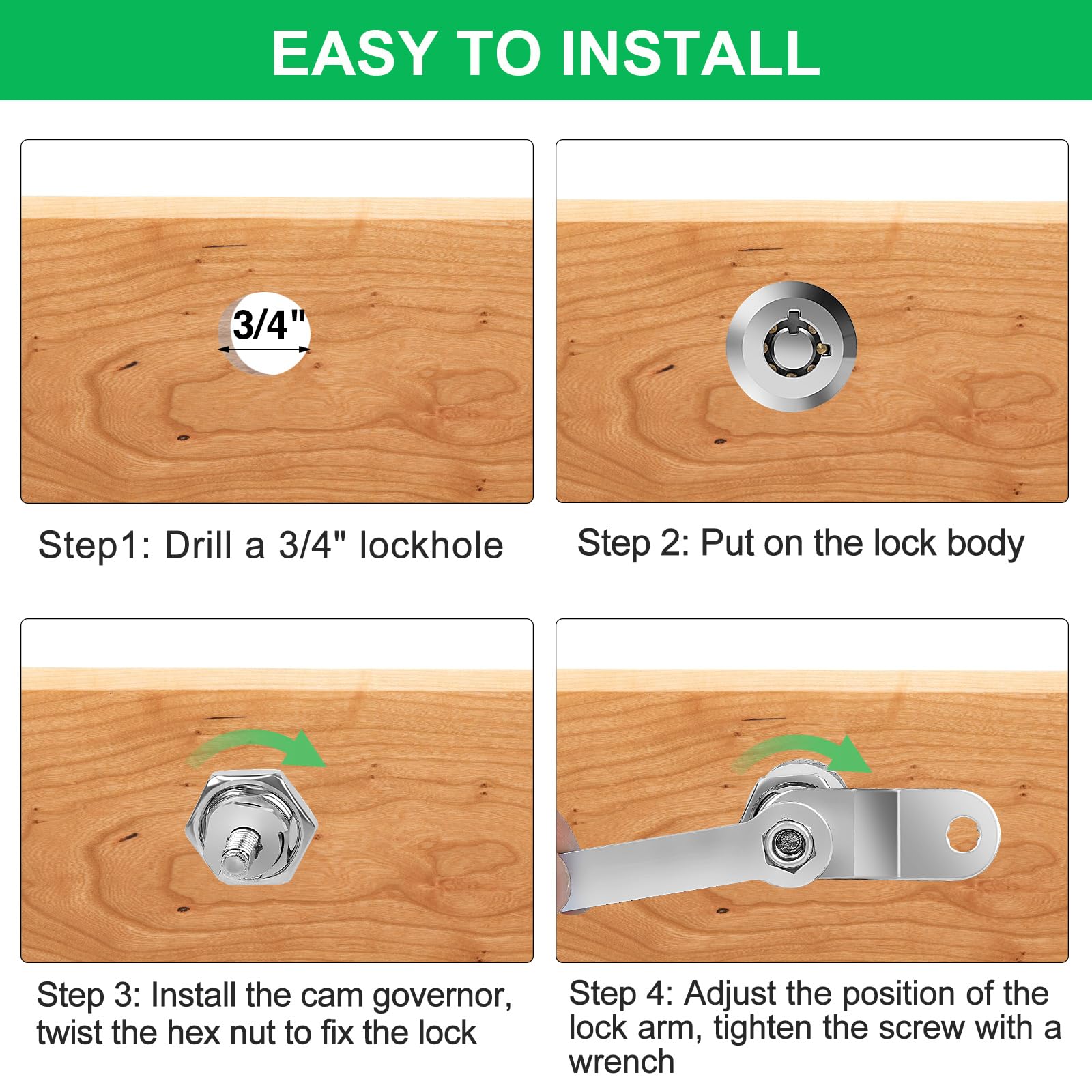

Replacing The Lock

Choose a lock that fits your toolbox size. Measure the hole before buying a replacement. Insert the new lock carefully into the hole. Secure it with screws or clips provided. Test the lock to ensure it works well and locks tightly.

Preventing Future Issues

Lubricate the lock regularly with graphite or oil. Keep the toolbox dry to avoid rust. Store the toolbox in a safe, dry place. Consider a lock cover to protect from dirt and water. Check the lock often for signs of wear or damage.

Credit: www.reddit.com

Frequently Asked Questions

How Do I Drill Out A Lock On A Toolbox Safely?

Use a drill with a metal drill bit. Wear safety goggles and gloves. Drill directly into the lock cylinder until it breaks. Avoid excessive force to prevent damage to the toolbox.

What Tools Are Needed To Drill Out A Toolbox Lock?

You need a power drill, metal drill bits, safety goggles, and gloves. A center punch helps mark the drill spot. These tools ensure precise and safe lock removal.

Can Drilling Out A Lock Damage My Toolbox?

Yes, improper drilling can damage the toolbox. Use the correct drill bit size and drill carefully. Focus on the lock cylinder to minimize damage to the toolbox surface.

How Long Does It Take To Drill Out A Toolbox Lock?

Drilling out a lock usually takes 5 to 10 minutes. Time depends on the lock type and drill power. Proper technique speeds up the process efficiently.

Conclusion

Drilling out a lock on a toolbox can be done with the right tools and care. Take your time and follow each step carefully. Always wear safety gear to protect yourself. Remember, this method works best when other options fail.

Keep your toolbox secure afterward to avoid future problems. Small actions can save you time and frustration. Stay calm and focused throughout the process. This simple guide helps you get back to work quickly.