If you’ve ever struggled to drill the perfect hole right in the center of a dowel, you’re not alone. Getting that exact spot can be tricky, but it’s key to making your project look professional and sturdy.

Imagine saving time, avoiding mistakes, and boosting your confidence with just a few simple steps. You’ll discover easy techniques to drill the center of a dowel every single time. Ready to master this essential skill and take your woodworking to the next level?

Let’s dive in!

Credit: woodworking.stackexchange.com

Choosing The Right Dowel

Choosing the right dowel plays a big role in drilling its center accurately. The correct dowel ensures better fit and strong joints. It also makes drilling easier and cleaner. This section helps you understand what types, materials, and sizes of dowels suit your project best.

Types Of Dowels

Wooden dowels are the most common. They work well for furniture and craft projects. Plastic dowels offer moisture resistance and flexibility. Metal dowels provide high strength for heavy-duty use. Each type has unique features that affect drilling and final results.

Material Considerations

Softwood dowels are easy to drill but may splinter. Hardwood dowels are tougher and hold screws better. Plastic dowels require sharp drill bits to avoid melting. Metal dowels need special drill bits for clean holes. Choose the material based on your tool and project needs.

Size Selection Tips

Pick a dowel diameter that fits your hole snugly. Too small, and the joint will be weak. Too big, and it may split the wood. Measure twice to ensure accuracy. Also, consider dowel length to match the thickness of your materials.

Credit: www.youtube.com

Essential Tools For Center Drilling

Drilling the center of a dowel requires precise tools to achieve accuracy. Using the right equipment ensures clean, straight holes. It helps avoid mistakes and saves time. Here are the essential tools you need for center drilling.

Drill Types And Bits

A handheld drill or drill press works well for center drilling. Drill presses provide more control and stability. Choose drill bits designed for wood, like brad-point bits. These bits create clean, centered holes without splintering. For small dowels, use smaller diameter bits to match the dowel size exactly.

Marking And Measuring Tools

Mark the exact center before drilling. Use a ruler or caliper to find the midpoint. A pencil or fine-tip marker helps draw clear guide lines. Center punches can create a small indent to keep the drill bit from slipping. Accurate markings make drilling easier and prevent errors.

Clamps And Supports

Secure the dowel with clamps or a vise. This prevents movement during drilling. Use soft jaws or padding to avoid damaging the wood. Holding the dowel steady improves accuracy and safety. Proper support also helps maintain the drill’s angle and depth.

Marking The Center Accurately

Marking the center of a dowel accurately is key to drilling clean and precise holes. A well-marked center guides the drill bit and prevents mistakes. Taking time to mark the center helps avoid damage and ensures strong joints. Use simple tools and careful steps to find the exact middle.

Using A Center Finder

A center finder tool makes marking easy and precise. Place the dowel in the tool’s cradle. The center finder shows the exact middle point. Mark the spot with a pencil or sharp awl. This method saves time and reduces errors. It works well for round and square dowels.

Manual Marking Techniques

Measure the dowel diameter with a ruler or caliper. Divide the measurement by two for the radius. Use a compass or pencil to mark the radius on both sides. Draw crossing lines from opposite edges to find the center. Mark this point clearly before drilling.

Avoiding Common Mistakes

Do not guess the center by eye. Avoid marks that are too light or unclear. Check measurements twice to prevent errors. Keep the dowel steady while marking. Misplaced marks cause off-center holes and weak joints. Accuracy matters for a professional finish.

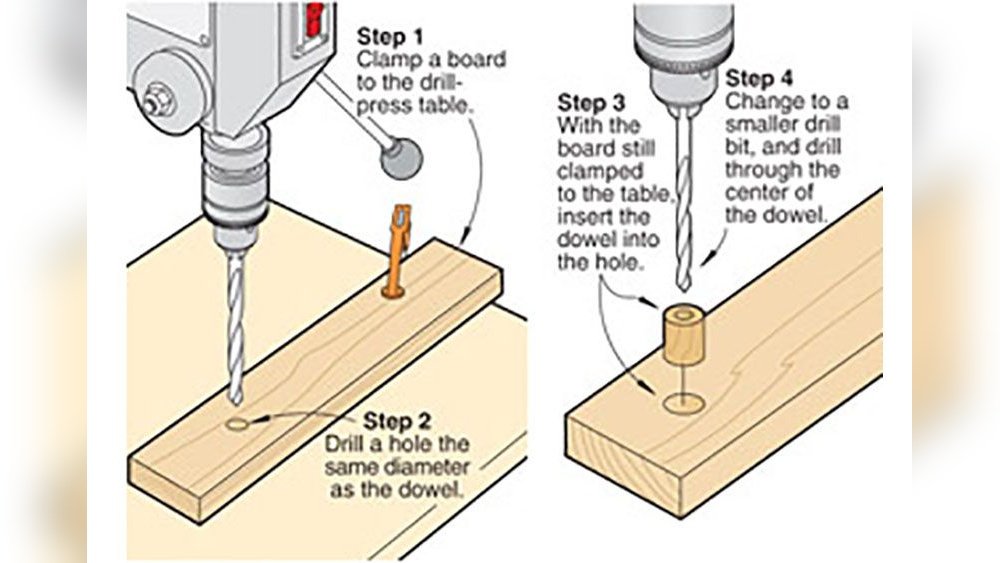

Step-by-step Drilling Process

Drilling the center of a dowel requires care and accuracy. Follow this step-by-step process to achieve a clean, precise hole. Each step ensures the dowel stays secure and the drill hits the exact middle point. This method helps avoid mistakes and improves your woodworking results.

Securing The Dowel

Hold the dowel firmly before drilling. Use a clamp or a vise to keep it still. This prevents the dowel from spinning or moving. A steady dowel helps create a straight, centered hole. Check that the dowel is level and well supported.

Setting Drill Speed And Depth

Choose a slow drill speed for better control. Fast speeds can cause the drill to slip or overheat. Set the drill depth using a stopper or tape on the bit. This stops the drill from going too deep. Proper speed and depth protect the dowel and drill bit.

Drilling Techniques For Precision

Start drilling with light pressure to mark the center. Keep the drill perpendicular to the dowel surface. Steady hands are key to avoid angled holes. Drill slowly and pause to clear wood shavings. This improves visibility and prevents bit clogging.

Troubleshooting Common Issues

Drilling the center of a dowel can be tricky. Small mistakes can cause problems like off-center holes or splintering. Knowing how to fix these common issues saves time and improves your project quality. Below are some tips to help you troubleshoot and get better results.

Preventing Drill Bit Wander

Drill bit wander happens when the bit slips from the center. It makes the hole uneven or off-target. To prevent this, start with a small pilot hole. Use a sharp drill bit and a steady hand. Clamping the dowel firmly stops movement. A center punch can mark the spot for the drill bit. This creates a small guide and keeps the bit in place.

Handling Splintering And Tear-out

Splintering occurs when wood fibers break around the hole. Tear-out looks like rough edges or chips. To reduce splintering, drill slowly and apply gentle pressure. Use a backing board under the dowel for support. Sharp drill bits cut cleaner holes and reduce tear-out. You can also score around the hole with a knife before drilling. This limits damage to the wood fibers.

Correcting Off-center Holes

Off-center holes weaken joints and look unprofessional. If you notice an off-center hole, try to realign your drill carefully. Use a smaller drill bit to widen the hole slightly and center it again. If the hole is too far off, you may need to start over with a new dowel. Mark the center clearly before drilling next time to avoid this issue.

Credit: www.youtube.com

Advanced Tips For Perfect Results

Drilling the center of a dowel needs precision and care. Advanced tips help achieve clean, accurate holes. These tips save time and reduce mistakes. They improve your woodworking quality and make the process smoother.

Using Jigs And Templates

Jigs hold the dowel steady during drilling. This prevents slipping and off-center holes. Templates guide the drill bit exactly where to go. You can make jigs from wood or metal. They keep each hole uniform and precise. Using a jig makes drilling safer and easier.

Drilling Multiple Dowels Consistently

Mark the drilling points clearly on all dowels. Use a stop collar on the drill bit for equal depth. Clamp dowels together in a jig for uniform holes. Drill slowly and steadily to avoid splintering. Consistency in speed and pressure improves results. This method saves time when working on many dowels.

Finishing Touches And Clean-up

Remove burrs around the hole edges with fine sandpaper. Check each hole for smoothness and correct size. Clean dust from the dowels before assembly. Use a small brush or compressed air for cleaning. Proper finishing ensures strong glue joints. Neat holes help the dowel fit perfectly.

Frequently Asked Questions

How Do I Find The Center Of A Dowel Accurately?

Use calipers or measure the diameter, then mark the midpoint with a pencil. This ensures precise centering for drilling.

What Drill Bit Size Is Best For Dowel Holes?

Choose a drill bit slightly smaller than the dowel diameter. This creates a snug fit and prevents splitting.

How Can I Prevent Dowel Splitting When Drilling?

Use a sharp drill bit and drill slowly. Clamping the dowel and backing it with scrap wood helps avoid splits.

Should I Drill Dowels Before Or After Assembly?

Drill dowels before assembly for better accuracy. Mark and drill carefully to ensure aligned joints during assembly.

Conclusion

Drilling the center of a dowel is easier with the right steps. Measure carefully to find the exact middle. Use a drill guide or mark clearly for precision. Take your time and drill slowly to avoid mistakes. This simple process helps you create strong, neat joints.

Practice a few times to build confidence. Now, you can complete your woodworking projects with better results. Keep tools sharp and workspace clean for safety. Small details make a big difference. Enjoy crafting with more accuracy and ease.