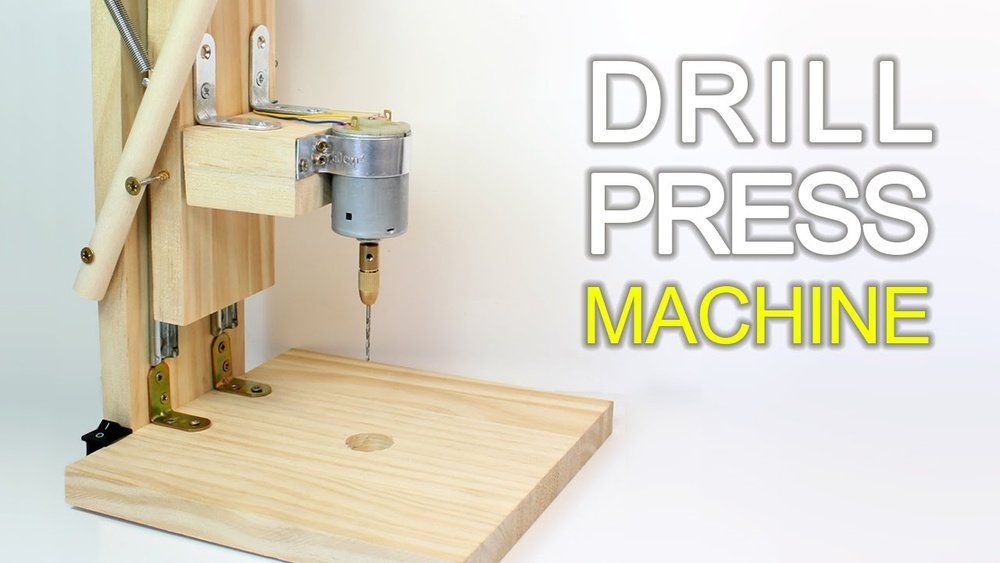

If you’re looking to take your DIY projects to the next level, a mini drill press can be a game changer. But buying one can be expensive and bulky.

What if you could make your own, right at home, using simple tools and materials? In this guide, you’ll discover easy steps to build a homemade mini drill press that fits perfectly in your workspace. Imagine the precision and control you’ll gain—without spending a fortune.

Keep reading, and you’ll soon have a tool that makes drilling easier, faster, and more accurate. Your next project deserves it!

Credit: www.homemadetools.net

Materials Needed

Building a homemade mini drill press starts with gathering the right materials. Choosing the correct tools and parts ensures your project goes smoothly. Quality materials help create a sturdy and safe drill press. Below is a list of what you will need.

Essential Tools

- Power drill with variable speed

- Drill bits set

- Screwdriver set

- Drill press vise or clamp

- Measuring tape or ruler

- Wrench set

- Electric drill stand (optional)

- Safety glasses

- Work gloves

Recommended Components

- Wooden or metal base board

- Metal or wooden vertical support rod

- Adjustable drill holder or chuck mount

- Spring or tension mechanism for drill movement

- Bolts, nuts, and washers

- Rubber feet for stability

- Metal brackets for support

- Small motor (if not using a power drill)

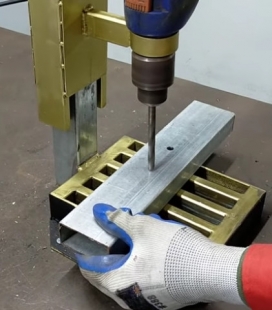

Credit: www.amazon.com

Choosing The Right Drill

Choosing the right drill is key to making a homemade mini drill press. The drill you pick affects how well your project turns out. It must fit your needs and work with your setup. Small details like power and size matter a lot. This guide helps you pick the best drill for your mini drill press.

Corded Vs Cordless Options

Corded drills get power from an outlet. They work without stopping. Perfect for long jobs where power is steady.

Cordless drills run on batteries. They move freely without a cord. Good for work in tight spaces or outside.

Choose corded for steady power. Pick cordless for ease and mobility.

Power And Size Considerations

Power is important for drilling through different materials. Higher power handles thicker wood or metal easily.

Size matters too. A smaller drill fits better in a mini drill press frame. It is easier to control and safer to use.

Balance power with size. A compact, strong drill works best for a homemade mini drill press.

Building The Base

Building the base is the first step in making a homemade mini drill press. A strong base keeps the drill steady during work. It supports the whole machine and helps make precise holes. Choosing the right material and preparing it carefully ensures the drill press works well and lasts long.

Selecting A Stable Platform

The base must be stable and heavy enough to hold the drill steady. Wood or metal boards work well. Choose a flat surface without cracks or warping. A wider base offers better balance. The platform should fit your workspace and be easy to handle. Stability reduces vibration and improves drilling accuracy.

Cutting And Preparing The Base Material

Cut the base material to your desired size. Use a saw or cutting tool suitable for wood or metal. Smooth the edges with sandpaper or a file to avoid splinters or sharp parts. Drill holes for mounting the drill and other parts. Clean the surface to remove dust and debris before assembly. Proper preparation helps the drill press hold parts firmly.

Constructing The Vertical Support

Constructing the vertical support is a key step in building a homemade mini drill press. This part holds the drill in place and keeps it steady. A strong, straight support ensures accurate drilling and safety during use.

Choosing the right materials and attaching the support firmly to the base are important. These steps help create a stable and durable drill press that works well every time.

Selecting Support Materials

Choose materials that are strong and easy to work with. Wood like hardwood or plywood works well for beginners. Metal can be used but needs special tools and skills.

Make sure the material is straight and free from cracks. The support should be thick enough to hold the drill without bending.

A 1×4 or 2×4 piece of wood often fits well for this project. It offers good height and strength. Avoid thin or weak wood that can break easily.

Attaching The Support To The Base

Start by placing the vertical support on the base. Position it at the center or slightly off-center for balance. Mark the spots for screws or nails.

Use wood screws to fix the support securely. Screws hold better than nails and allow for adjustments. Drill pilot holes to prevent the wood from splitting.

Check that the support stands straight before tightening screws fully. A level or square tool helps with this step. The support must be stable to keep the drill steady during use.

Mounting The Drill

Mounting the drill is a key step in building your homemade mini drill press. It holds the drill steady for precise work. A firm mount prevents wobbling and keeps the drill aligned with the workpiece. You need a strong and adjustable system that fits your drill well.

Creating A Secure Holder

Start by making a holder that grips the drill tightly. Use wood or metal to build a frame around the drill body. Cut the material to match the drill’s shape closely. Add padding inside to protect the drill and stop slipping. Secure the holder with screws or bolts for a firm fit. This keeps the drill from moving during operation.

Adjusting For Drill Size

Drills come in different sizes. Your holder must adjust to fit various drills. Use slots or adjustable clamps in the holder design. This allows you to tighten or loosen the grip as needed. Test the fit with your drill before final assembly. A flexible holder saves time and works with multiple tools.

Credit: www.youtube.com

Adding The Drill Press Handle

Adding the drill press handle is a key step in building your homemade mini drill press. The handle controls the drill’s up and down movement. It needs to be strong and easy to use. A good handle makes drilling safer and more precise.

Designing A Lever Mechanism

Start by planning a simple lever mechanism. The lever should move smoothly and not require much force. Use a sturdy rod or metal bar as the lever arm. The length of the lever affects control and power. A longer lever means easier movement but less space.

Create a pivot point where the lever will rotate. This can be a bolt or pin fixed to the drill press frame. Ensure the lever moves freely around this pivot. Attach a connecting link from the lever to the drill chuck holder. This link transfers the lever’s motion to the drill bit.

Attaching The Handle To The Support

Choose a solid support piece for the handle attachment. Wood or metal both work well. Drill a hole in the support to hold the pivot bolt. Insert the lever arm and secure it with a nut or cotter pin.

Test the handle by moving it up and down. The drill bit should move smoothly without binding. Tighten all fasteners but keep movement easy. Add a grip to the handle end for comfort. Rubber or wood are good materials for this.

Ensuring Precision And Stability

Ensuring precision and stability is key to a successful homemade mini drill press. Without these, your drill may wobble or drill uneven holes. A steady base and careful alignment make a big difference.

Precision means the drill moves exactly where you want. Stability means the drill press does not shake or move during use. Both help create clean, accurate holes every time.

Aligning The Drill

Start by checking the drill bit is straight and centered. Use a square or ruler to measure alignment. Adjust the drill mount until the bit points straight down. Make sure the drill bit does not touch the sides of the frame.

Keep the drill bit perpendicular to the base. This ensures holes go in straight. Tighten all screws to hold the drill firmly in place.

Testing For Smooth Operation

Turn the drill press on without a drill bit first. Listen for any unusual noises or vibrations. The drill should spin smoothly and quietly.

Lower the drill bit slowly to the base. It should move without sticking or shaking. If the drill does not move smoothly, check the guide rods and bearings. Lubricate or adjust parts as needed for smooth motion.

Safety Tips

Safety is the top priority when using a homemade mini drill press. Careful attention protects you from accidents and injuries. Follow these safety tips to work confidently and avoid harm.

Protective Gear

Wear safety glasses to guard your eyes from flying debris. Use ear protection if the drill press is loud. Gloves protect your hands but avoid loose gloves that can catch on parts. Wear a dust mask if you drill materials that create dust. Choose clothing that fits well and does not hang loose.

Safe Operating Practices

Secure the workpiece firmly before drilling. Keep hands away from the drill bit. Always switch off and unplug the drill press before changing bits. Check the drill press for loose parts before use. Work in a well-lit area to see clearly. Do not force the drill; let it cut at its own speed.

Maintenance And Upgrades

Maintaining your homemade mini drill press ensures it stays reliable and safe. Regular care helps you avoid costly repairs. Upgrading parts can improve performance and make your work easier. Small changes often bring big benefits. Focus on simple steps to keep your drill press in top shape.

Regular Checks

Inspect your drill press before each use. Check for loose screws or bolts. Tighten any that feel wobbly. Look at the drill bit for damage. Replace dull or broken bits right away. Clean dust and debris from moving parts. Lubricate the spindle and gears with light oil. This reduces friction and wear. Test the motor to ensure smooth running. Watch for unusual noises or vibrations. Address problems quickly to prevent bigger issues.

Adding Features For Better Performance

Upgrade your drill press with useful features. Add a depth stop to control drilling depth. This ensures consistent holes every time. Install a small LED light for better visibility. Attach a clamp or vise to hold materials firmly. It increases safety and precision. Consider a speed controller to adjust motor speed. Different materials need different speeds for best results. Adding a dust collection system keeps your workspace clean. These simple upgrades enhance your drill press function and ease of use.

Frequently Asked Questions

What Materials Are Needed For A Mini Drill Press?

You need a small motor, drill chuck, wooden base, metal rods, and screws. These materials ensure stability and precision.

How Do I Assemble A Homemade Mini Drill Press?

Attach the motor to the base, fix the drill chuck, and mount the rods. Align everything for smooth vertical movement.

Can I Use A Mini Drill Press For Small Projects?

Yes, it’s perfect for small, precise drilling tasks like jewelry or electronics. It offers control and accuracy.

How Do I Ensure Safety When Using A Mini Drill Press?

Always wear safety goggles, secure your workpiece, and keep hands clear. Use the press on a stable surface.

Conclusion

Building a homemade mini drill press can be simple and rewarding. You only need a few basic tools and materials. This project saves money and helps you learn new skills. Take your time and follow each step carefully. Soon, you will have a useful tool for small drilling jobs.

Enjoy working on your projects with confidence and precision. Keep practicing, and your skills will improve quickly. A homemade mini drill press is a great addition to any workshop.