Are you tired of uneven holes and wasted material when using your drill press? Mastering how to make the right feed on your drill press can change everything.

It’s not just about pushing the drill down—you need control, precision, and the right technique to get perfect results every time. You’ll discover simple steps that anyone can follow to improve your feed rate. By the end, you’ll save time, reduce mistakes, and make your projects look professional.

Ready to take your drill press skills to the next level? Keep reading and unlock the secret to smooth, accurate drilling.

Credit: canadianwoodworking.com

Choosing The Right Drill Press

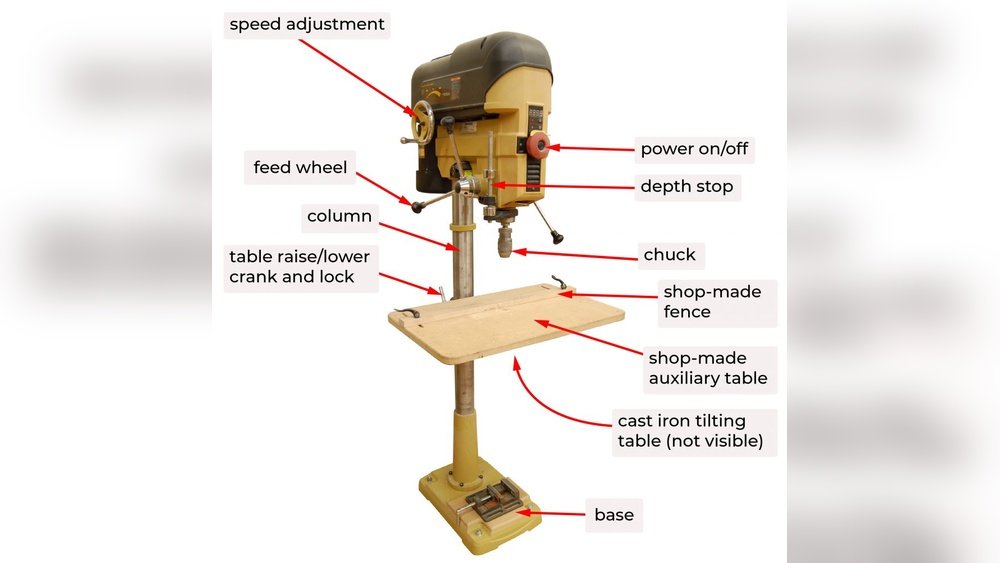

Choosing the right drill press is important for making a good feed. The right drill press helps you work safely and accurately. It also saves time and effort. Knowing what type of drill press fits your needs is the first step. Also, understanding key features helps you pick a reliable machine. Lastly, the drill bits must match the drill press and the material you work on.

Types Of Drill Presses

There are several types of drill presses. A benchtop drill press is small and fits on a table. It is good for light jobs and small spaces.

A floor drill press is larger and stands on the floor. It is stronger and can handle bigger jobs. These are best for heavy-duty work.

Radial drill presses have an arm that moves the drill head. This type allows more flexibility and can reach different spots on large pieces.

Key Features To Consider

Look at the drill press motor power. Higher power means it can drill harder materials easily. Check the speed settings. Multiple speeds help you match the speed to the material.

The size of the drill chuck matters. It must hold the drill bits firmly. The depth stop feature controls how deep the drill goes. This is useful for precise drilling.

Also, consider the table size and adjustability. A bigger table supports larger workpieces. Tilting and rotating tables help drill at angles.

Selecting Suitable Drill Bits

Choose drill bits that fit your drill press chuck size. Use bits made for the material you will drill. For example, wood bits for wood and metal bits for metal.

Sharp drill bits make clean holes and reduce pressure. Dull bits can damage the material and the drill press. Replace or sharpen bits often for the best results.

Special drill bits like brad-point or spade bits can improve accuracy for certain jobs. Match the bit type to your project needs.

Setting Up For Accurate Feed

Setting up for accurate feed on a drill press is vital for clean and precise holes. Proper setup saves time and prevents damage to your workpiece and drill bit. Follow these simple steps to ensure a smooth and accurate drilling process.

Securing The Workpiece

Always clamp the workpiece firmly to the drill press table. Use a vise or clamps to stop any movement during drilling. A steady workpiece means a cleaner hole and less chance of injury.

Adjusting The Drill Speed

Match the drill speed to the material you are working with. Slow speeds work best for hard metals. Faster speeds suit softer materials like wood or plastic. Adjust the speed control before starting the drill press.

Aligning The Drill Bit

Check that the drill bit is straight and centered in the chuck. Lower the bit slowly to touch the mark on your workpiece. Proper alignment helps avoid off-center holes and bit breakage.

Feed Techniques For Precision

Precision in drilling depends a lot on feed techniques. Proper feed control helps avoid mistakes and ensures clean holes. Understanding how to feed the drill press correctly improves your work quality and safety.

Different feed methods suit different projects and materials. Learning these methods gives you better control over the drill bit and workpiece. This section explains key feed techniques for more accurate drilling.

Manual Feed Methods

Manual feed means using your hand to lower the drill bit. It allows careful control of speed and pressure. This method works well for delicate or small pieces. Slow and steady movement reduces the risk of slipping or breaking the bit. Always hold the handle firmly and guide the bit straight down.

Using Feed Handles Effectively

Feed handles help move the drill press spindle smoothly. Use all three handles evenly to keep balance. This prevents the bit from wobbling or tilting. Push the handles slowly to avoid sudden movements. Practice steady, even strokes to maintain control. Proper use of feed handles reduces wear on the machine.

Applying Consistent Pressure

Pressure must be steady and not too hard. Too much force can damage the drill bit or workpiece. Too little pressure causes the bit to stall or burn. Focus on a uniform push that matches the material hardness. Consistent pressure helps the drill cut cleanly and last longer. Check your feed speed and adjust pressure as needed.

Credit: stonedesignbysantos.com

Enhancing Feed Control

Controlling the feed on a drill press is key to making clean, precise holes. Enhancing feed control helps avoid mistakes and improves safety. Small changes can make a big difference in how smoothly the drill moves through the material.

Proper feed control protects the drill bit and workpiece. It also helps maintain steady pressure and speed. This section explains simple ways to improve feed control on your drill press.

Installing Feed Rate Attachments

Feed rate attachments help control how fast the drill moves down. These attachments attach to the drill press handle or spindle. They allow you to set a consistent feed speed without guesswork. Using these tools can prevent pushing too hard or too fast. This reduces drill bit wear and improves hole quality.

Utilizing Depth Stops

Depth stops limit how far the drill bit moves into the material. They are easy to install and adjust. Setting a depth stop ensures consistent hole depths every time. This prevents drilling too deep, which can damage the workpiece or table. Depth stops also speed up repetitive drilling tasks.

Maintaining Smooth Feed Movement

Smooth feed movement reduces jerks and uneven pressure. Keep the drill press spindle clean and lubricated. Check the handle and feed mechanism for any stiffness. Use steady, even pressure on the feed lever. Avoid forcing the drill bit through the material. Smooth movement extends tool life and improves accuracy.

Troubleshooting Common Issues

Troubleshooting common issues on a drill press helps improve feed quality. These problems can cause poor results and damage your workpiece. Fixing these issues keeps your drilling process smooth and safe.

Dealing With Bit Wander

Bit wander happens when the drill bit moves off the mark. This causes inaccurate holes and rough edges. To stop bit wander, use a center punch to make a small dent on the workpiece. This dent guides the bit and keeps it steady.

Also, check that the drill bit is sharp and not dull. A dull bit slips easily and causes wandering. Tighten the chuck firmly to hold the bit in place. Loose bits lead to unstable drilling.

Preventing Workpiece Damage

Workpiece damage occurs from too much pressure or wrong feed speed. Use a slow feed rate for hard materials to avoid cracks. Secure the workpiece firmly with clamps or a vise. Movement during drilling can ruin the surface.

Lubricate the drill bit for metal or tough materials. This reduces heat and wear on the bit and workpiece. Always clean chips and dust to keep the work area clear and safe.

Fixing Uneven Feed Rates

Uneven feed rates cause rough holes and tool wear. Check the feed lever or handle for smooth operation. Tighten or adjust loose parts that affect feed control.

Practice steady pressure on the feed lever. Sudden pushes or pulls create uneven feed. Adjust the drill press feed mechanism if needed to maintain consistent speed.

Maintenance For Optimal Performance

Maintaining your drill press is key for smooth and accurate feed. Regular care keeps the machine working well and prevents damage. Small steps can extend the life of your drill press and improve safety.

Lubricating Moving Parts

Lubricate all moving parts often. Use machine oil or grease made for metal tools. Focus on the feed mechanism, spindle, and gears. This reduces friction and wear. Clean old grease before applying new oil. Too little lubrication causes hard movement. Too much causes dirt buildup.

Checking And Replacing Components

Check belts, pulleys, and bearings regularly. Look for cracks, wear, or looseness. Replace parts that look worn or broken. Tighten any loose screws or bolts. Faulty components make the feed uneven or unsafe. Use parts made for your drill press model. Keep extra parts on hand for quick fixes.

Cleaning The Drill Press

Clean dust, metal shavings, and grease from the drill press. Use a soft brush or cloth. Avoid water or harsh chemicals. Clean the table, base, and moving parts. Dirt and debris cause poor feed and damage. Regular cleaning keeps the drill press precise and safe.

Credit: www.hobby-machinist.com

Frequently Asked Questions

What Is Feed On A Drill Press?

Feed on a drill press refers to the controlled movement of the drill bit into the workpiece. It ensures smooth cutting and accurate hole depth. Proper feed prevents bit damage and improves drilling efficiency.

How To Adjust Feed Rate On A Drill Press?

Adjust the feed rate by changing the pressure applied on the feed lever. Some drill presses have adjustable feed speed settings or gears. Start slow and increase feed gradually for better control and precision.

Why Is Proper Feed Important In Drill Press Work?

Proper feed prevents drill bit overheating and reduces wear. It ensures clean, accurate holes and extends tool life. Incorrect feed rates can cause bit breakage and damage to the workpiece.

Can Feed On Drill Press Be Automated?

Yes, many modern drill presses feature automatic feed mechanisms. These systems control the bit’s downward motion for consistent drilling speed and depth. Automation improves productivity and precision in repetitive drilling tasks.

Conclusion

Making feed on a drill press needs care and focus. Always set your speed and feed rate correctly. Use the right tools and keep them sharp. Watch the drill’s progress closely to avoid mistakes. Safety comes first—wear goggles and keep hands clear.

Practice helps you get better and faster. With time, drilling becomes smooth and precise. Follow these steps for steady and safe drilling results.