If you want to get the most out of your drill press, mounting a drill press vise is a game-changer. It keeps your work steady, precise, and safe, saving you time and frustration.

But if you’re unsure how to mount it correctly, you might end up wasting effort or even damaging your tools. Don’t worry—this guide will walk you through every simple step to set up your drill press vise like a pro.

By the end, you’ll feel confident and ready to tackle your projects with ease. Keep reading to learn exactly how to mount a drill press vise the right way.

Credit: www.kakaindustrial.com

Choosing The Right Drill Press Vise

Choosing the right drill press vise is key for safe and accurate work. The right vise holds your material steady. It helps make precise cuts and holes. Picking the best type, material, and size improves your drilling experience. Here is what to consider before buying a drill press vise.

Types Of Drill Press Vises

There are several types of drill press vises. The most common is the standard vise. It holds flat or square objects firmly. A swivel base vise allows you to rotate the workpiece. This helps in drilling at different angles. A quick-release vise lets you open and close the jaws fast. It saves time when changing materials. Choose the type that fits your projects.

Material And Build Quality

Look for vises made from strong materials. Cast iron is popular for its strength and durability. Steel vises are tough and resist wear well. Avoid cheap plastic or light metals. They may break or loosen under pressure. A good vise has smooth jaw surfaces to protect your work. Check for solid construction and tight parts.

Size And Jaw Capacity

Size matters for your drill press vise. The jaw capacity is how wide the jaws open. It determines the size of material you can clamp. Small vises work for delicate, small pieces. Larger vises hold bigger, heavier materials. Match the size to your common tasks. Too small limits work, too big may be bulky.

Preparing Your Drill Press

Preparing your drill press is a key step before mounting a drill press vise. A clean and stable setup helps ensure accurate drilling. Taking time to prepare the drill press table improves safety and results.

Start by making sure the work area is clear and the drill press is off. Proper preparation prevents mistakes and saves time during your project.

Cleaning The Drill Press Table

Remove any dust, dirt, and metal shavings from the table surface. Use a brush or cloth to wipe it down thoroughly. Dirt or debris can cause the vise to sit unevenly. A clean table allows the vise to clamp firmly and stay in place.

Checking For Level And Stability

Check if the drill press table is level using a small spirit level. Place the level on the table and adjust the table height or position if needed. A level table ensures the vise holds the workpiece straight. Also, make sure the drill press base is stable and does not wobble. Stability keeps the drill press safe and steady during use.

Positioning The Vise

Positioning the drill press vise correctly is key for safe and accurate work. Proper placement helps keep your material steady and ensures precise drilling. Take your time to set the vise in the right spot before tightening it down.

Aligning With The Drill Bit

Start by placing the vise on the drill press table. Adjust it so the jaws line up with the drill bit. The drill bit should be centered over the space where the material will sit in the vise. This alignment prevents the bit from hitting the vise itself.

Move the vise gently back and forth to find the perfect spot. Check the alignment by lowering the drill bit slowly. Stop before the bit touches anything. Make small adjustments until the drill bit is directly above the vise jaws.

Securing The Vise Placement

Once aligned, secure the vise firmly to the drill press table. Use the bolts or clamps that came with your vise. Tighten them enough to stop any movement during drilling. A loose vise can cause errors and is unsafe.

Double-check the vise position after tightening. Make sure it has not shifted from the drill bit alignment. If it has, loosen and reposition the vise again. A well-secured vise keeps your project steady and your work precise.

Credit: www.hobby-machinist.com

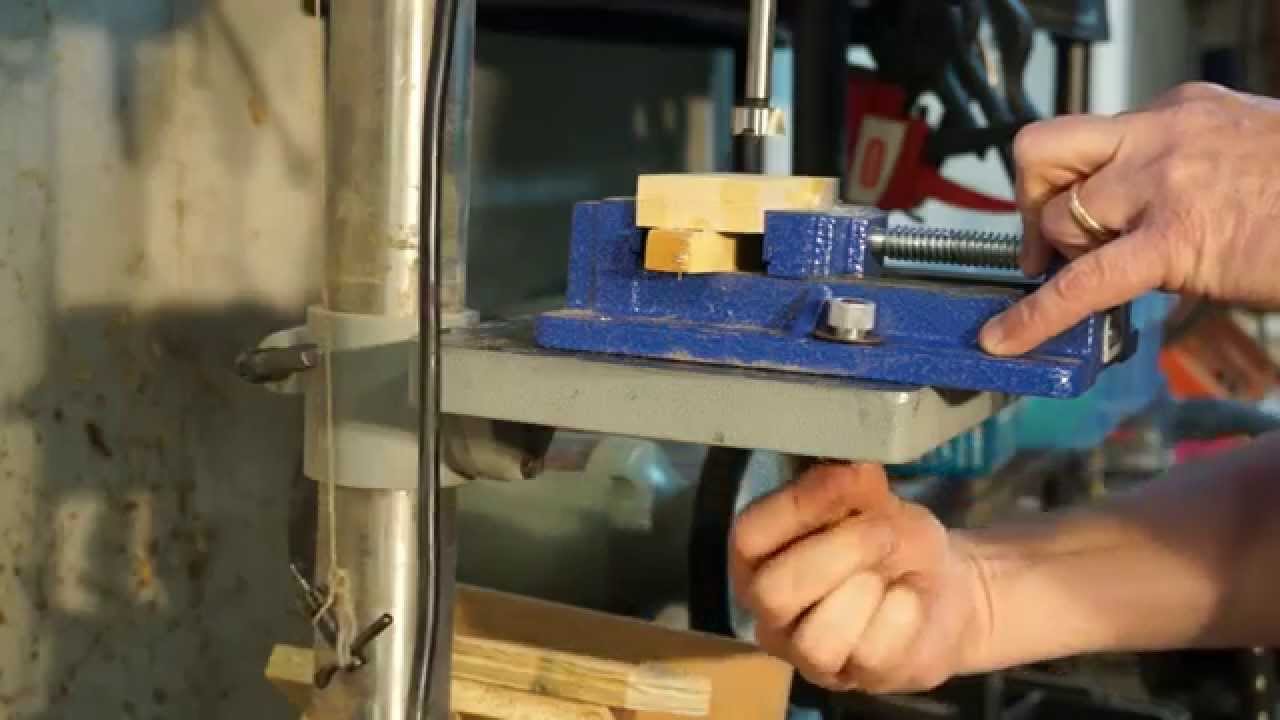

Mounting The Vise

Mounting the vise on your drill press is a key step for safe and accurate work. A properly mounted vise keeps your materials steady. This prevents slipping and ensures precise drilling. Follow simple steps to secure the vise firmly on the drill press table.

Use the right tools and methods to avoid damage. Mounting the vise correctly saves time and improves your results.

Using Bolts And Clamps

Place the vise on the drill press table. Align the holes of the vise base with the table slots. Use bolts that fit these holes. Insert the bolts through the holes and into the slots below.

Use washers with bolts to spread the pressure evenly. Tighten the bolts just enough to hold the vise in place. If your drill press table has no slots, use clamps instead. Position clamps over the vise base and table edge. Tighten clamps securely to hold the vise steady.

Tightening For Firm Grip

Check the vise position before fully tightening. Adjust it so it sits flat and straight. Use a wrench to tighten bolts firmly. Avoid over-tightening to prevent damage to the table or vise.

For clamps, turn the handles until the vise does not move. Test by trying to shift the vise with your hand. A firm grip means no movement. Proper tightening ensures safety and precise drilling.

Testing The Setup

After mounting your drill press vise, testing the setup is essential. This step ensures the vise holds materials firmly and works smoothly. Testing helps avoid mistakes during drilling and keeps your work safe.

Checking For Movement

Start by placing a workpiece in the vise jaws. Tighten the vise and try to move the workpiece with your hand. There should be no wobble or slip. If the workpiece moves, the vise may not be mounted tightly or correctly. Check the base bolts and tighten them as needed. Also, ensure the mounting surface is flat and clean.

Adjusting Jaw Alignment

Look closely at the vise jaws. They must be parallel and meet evenly. Uneven jaws can cause poor grip and damage the workpiece. Use a ruler or square to check jaw alignment. Adjust the jaws by loosening the mounting bolts slightly. Move the vise or jaws until aligned. Then, retighten the bolts firmly. Proper jaw alignment improves drilling accuracy and safety.

Credit: www.youtube.com

Maintenance Tips

Maintaining your drill press vise is key to its long life and strong hold. Simple care steps keep it working smoothly and safely. Check it often to avoid rust and wear. Clean and oil parts regularly to keep the vise tight and easy to move.

Regular Cleaning

Remove dust and metal shavings after each use. Use a soft brush or cloth to clean all surfaces. Wipe down the jaws to stop rust build-up. Avoid water, which can cause corrosion. Keep the base free of dirt for better stability.

Lubricating Moving Parts

Apply light machine oil to the screw and slide areas. This reduces friction and prevents wear. Use oil sparingly to avoid attracting dirt. Move the handle back and forth to spread the lubricant. Repeat lubrication every few weeks for best results.

Frequently Asked Questions

How Do You Attach A Drill Press Vise Securely?

To attach a drill press vise securely, align the vise base with the drill press table slots. Use bolts and washers to fasten the vise tightly. Ensure the vise is firmly clamped to prevent movement during drilling.

What Tools Are Needed To Mount A Drill Press Vise?

You need bolts, washers, nuts, a wrench, and an Allen key. These tools help secure the vise to the drill press table safely. Having a measuring tape can also help align the vise precisely.

Can I Mount A Drill Press Vise Without T-slots?

Yes, you can mount a vise using clamps or by drilling holes in the table. However, T-slots provide the most secure and adjustable mounting option for stability.

How To Align The Vise On A Drill Press Table?

Place the vise parallel to the drill press spindle. Use a square to check alignment. Proper alignment ensures accurate drilling and prevents material damage.

Conclusion

Mounting a drill press vise is simple with clear steps. Secure the vise tightly to avoid movement during work. Always check alignment to keep your cuts accurate. Using the right tools makes the process faster and safer. Take your time and follow instructions carefully.

Practice will help you get comfortable with the setup. A well-mounted vise improves your project quality and safety. Now, you can work with more control and confidence.